Cork skirtboard and production method

A production method and skirting technology, applied in the field of skirting, can solve problems such as difficult processing, single line type, large natural color difference, etc., and achieve the effects of overcoming difficult processing, reasonable structure of finished products, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

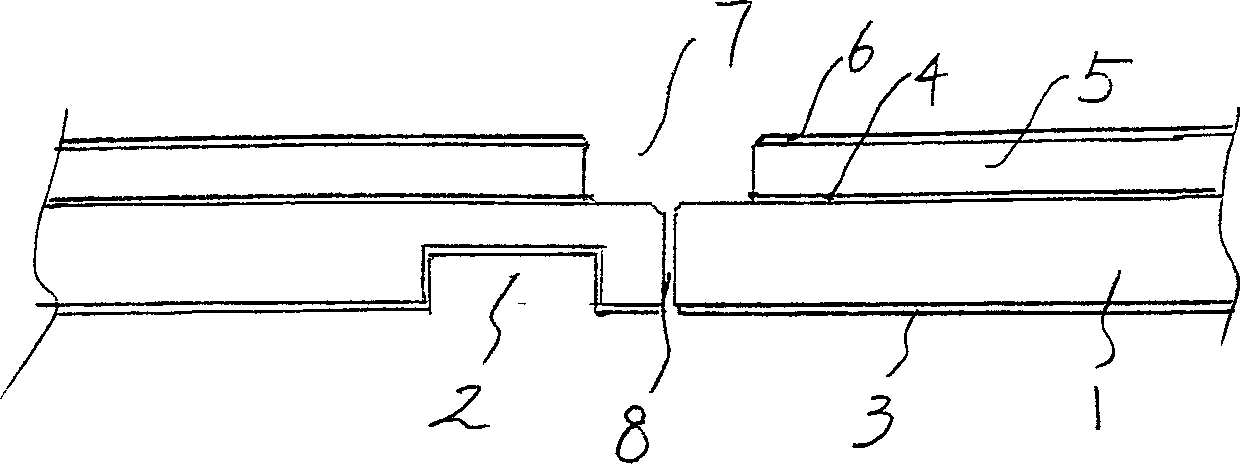

[0016] (1) According to the visual or linear design requirements, the base material is sawed into strips, and processed into the required shape by four-sided planing (at least one side is wireless), and the wire groove 2 is set on the back of the base material 1. The depth of the wire groove is at Within 60% of the substrate thickness. And coat the moisture-proof layer 3 on the back side of the substrate (wireless surface);

[0017] (2) Calculate the specifications of the cork veneer layer required at the beginning according to the line shape of the substrate, apply the glue layer 4 on the front side of the substrate, and attach the cork veneer layer 5 to the front side of the substrate by one or more times of heating and molding skirting molding blanks;

[0018] (3) According to the requirements of visual or linear design, the surface of the skirting line blank is polished into a smooth and flat surface with a multi-curved surface sander to form a semi-finished skirting line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com