Method for manufacturing nanocarbon-metal composite material

一种金属复合材料、纳米碳材料的技术,应用在纳米技术、纳米技术、纳米结构制造等方向,能够解决降低表面硬度和耐磨损性等问题,达到提高表面硬度、提高能量节省的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The invention will be described by means of several examples, which are not intended to limit the scope of protection of the invention.

[0036] 1. Carbon nanomaterials used in the experiment:

[0037] Carbon nanofibers (hereinafter abbreviated as CNF) with a diameter of 1.0-150 nm and a length of 100 μm.

[0038] 2. Metal matrix materials used in the experiment:

[0039] Magnesium alloy die casting (JIS H 5303 MDC1D) chips (hereinafter abbreviated as MD1D).

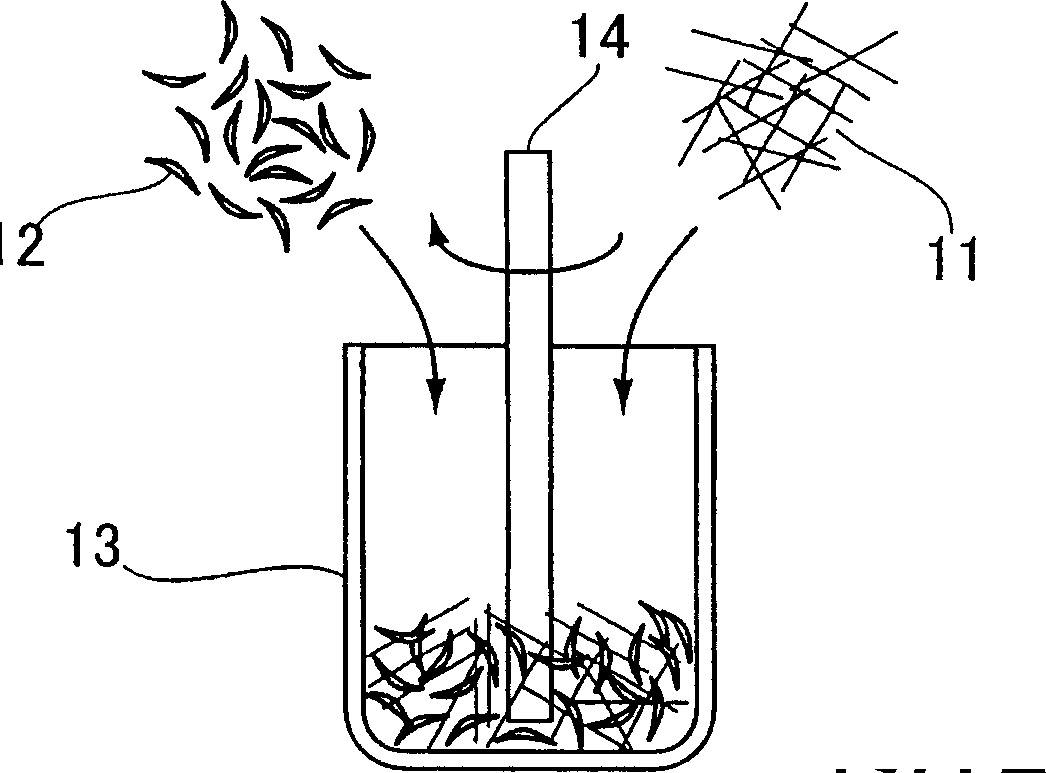

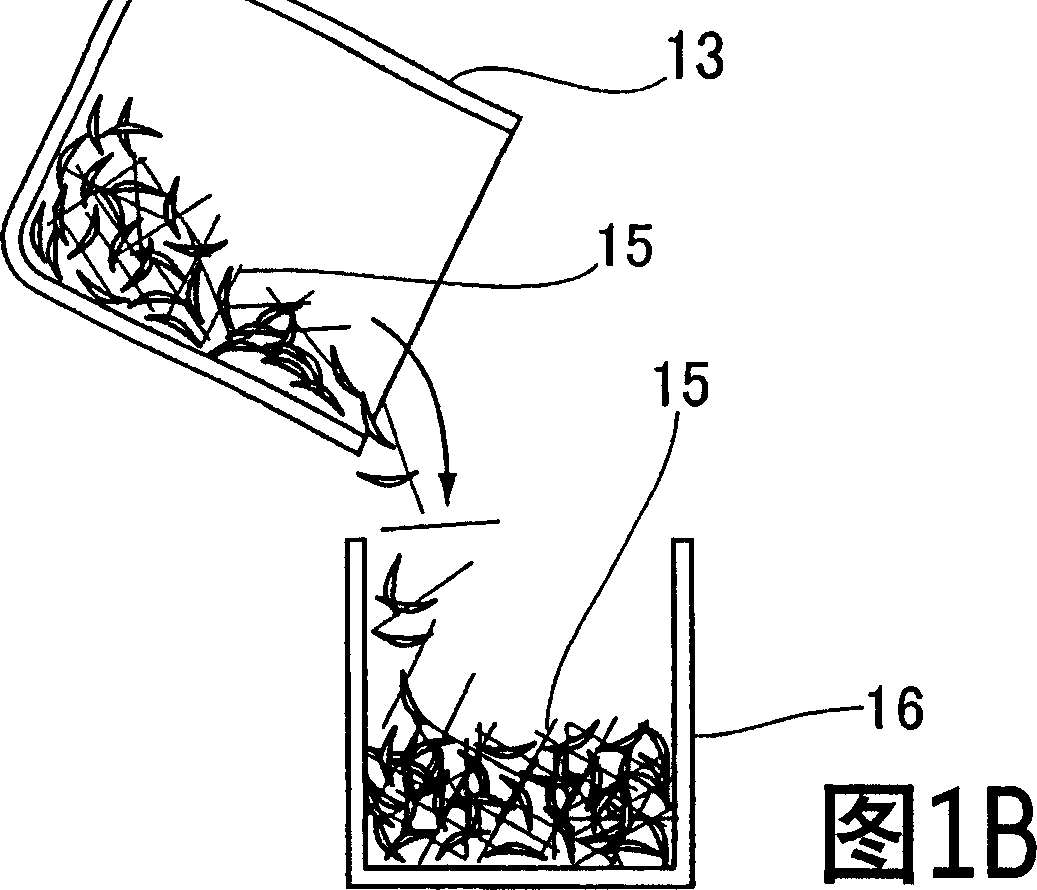

[0040]3. Mixing steps:

[0041] 3.1. Mixing ratio:

[0042] Sample No. 01: 5vol% CNF / 95vol% MD1D

[0043] Sample No. 02: 5vol% CNF / 95vol% MD1D

[0044] Sample No. 03: 10vol% CNF / 90vol% MD1D

[0045] Sample No. 04: 10vol% CNF / 90vol% MD1D

[0046] Sample No. 05: 15vol% CNF / 85vol% MD1D

[0047] Sample No. 06: 15vol% CNF / 85vol% MD1D

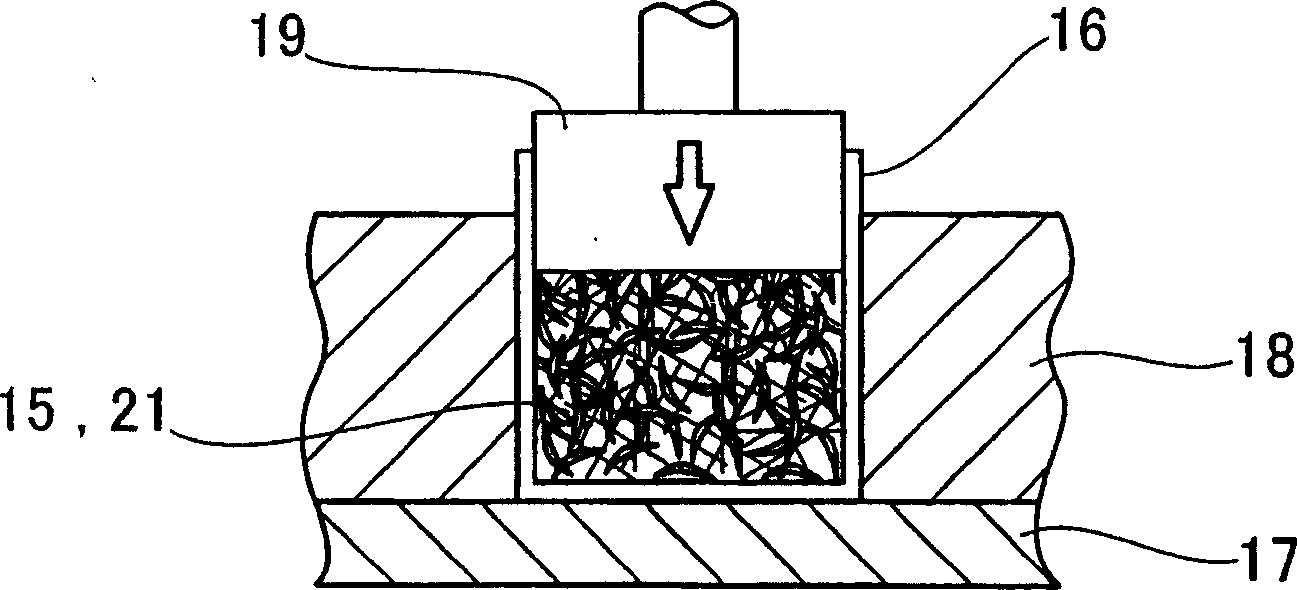

[0048] 4. Coating steps (for samples No. 01-06):

[0049] Use aluminum cans and foil for wrapping.

[0050] 5. Heating steps (for samples No. 01-06):

[0051] Heating tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com