Multifunctional valve

A multi-functional valve and valve body technology, which is applied in the direction of lifting valve, valve details, valve device, etc., can solve the problems of increasing equipment cost, labor time, troublesome operation lever, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

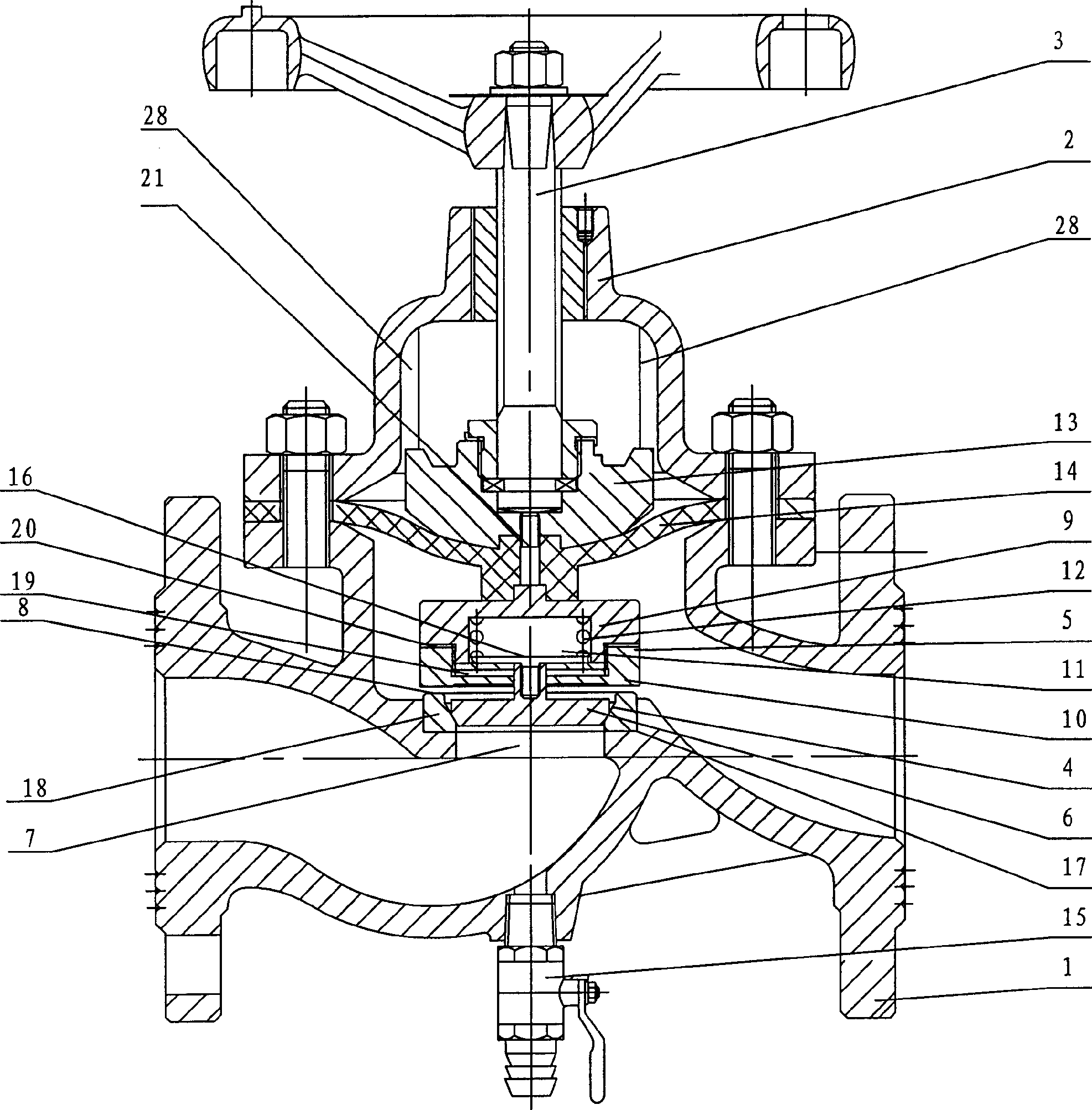

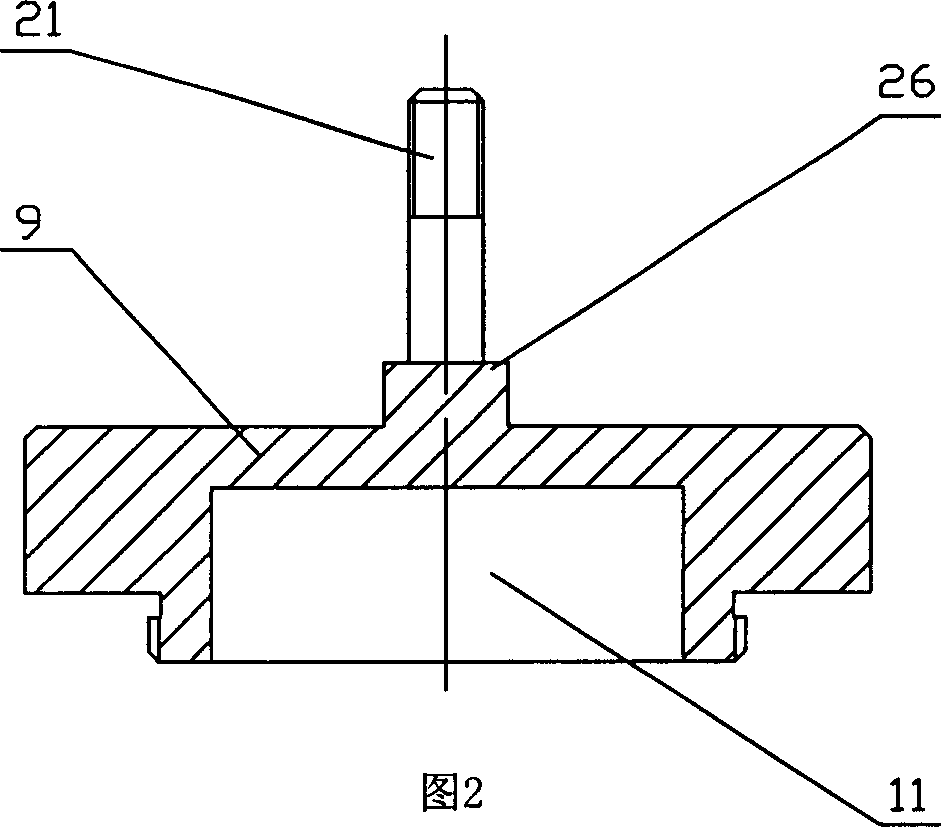

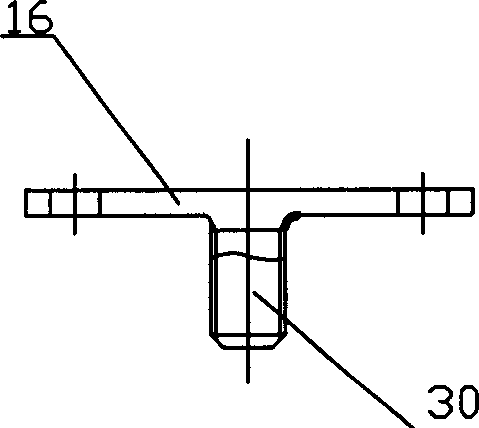

[0015] Such as figure 1 ,figure 2, image 3 , Figure 4 , Figure 5 As shown, the multifunctional valve of the present invention includes a valve body 1, a valve cover 2 and a valve stem 3, the upper part of the valve stem 3 has an external thread, the valve cover 2 is provided with an internal thread matched with the external thread of the valve stem 3, and the valve stem 3 is provided with a valve flap, the valve flap includes a cut-off valve flap 5 and a conical valve flap 6, wherein the conical valve flap 6 and the cut-off valve flap 5 are connected to each other, and the conical valve flap 6 can be moved up and down relative to the cut-off valve flap 5 along the axial direction Elastic expansion and contraction; the material inlet 7 of the valve body 1 is provided with a conical surface 4 corresponding to the conical valve disc 6, and the inner wall of the valve body 1 adjacent to the material inlet 7 is provided with a cut-off valve disc matching surface 8, when the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com