Cleaning, filling and plugging device for glass bottle or similar container

A technology of stoppering device and glass bottle, which is applied in the field of filling and stoppering device and cleaning, which can solve the problems of inconvenient debugging, maintenance and repair, large production line area, and difficulty in meeting hygienic standards, and reduce broken bottles. The effect of high efficiency, reduced floor space and shortened movement distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

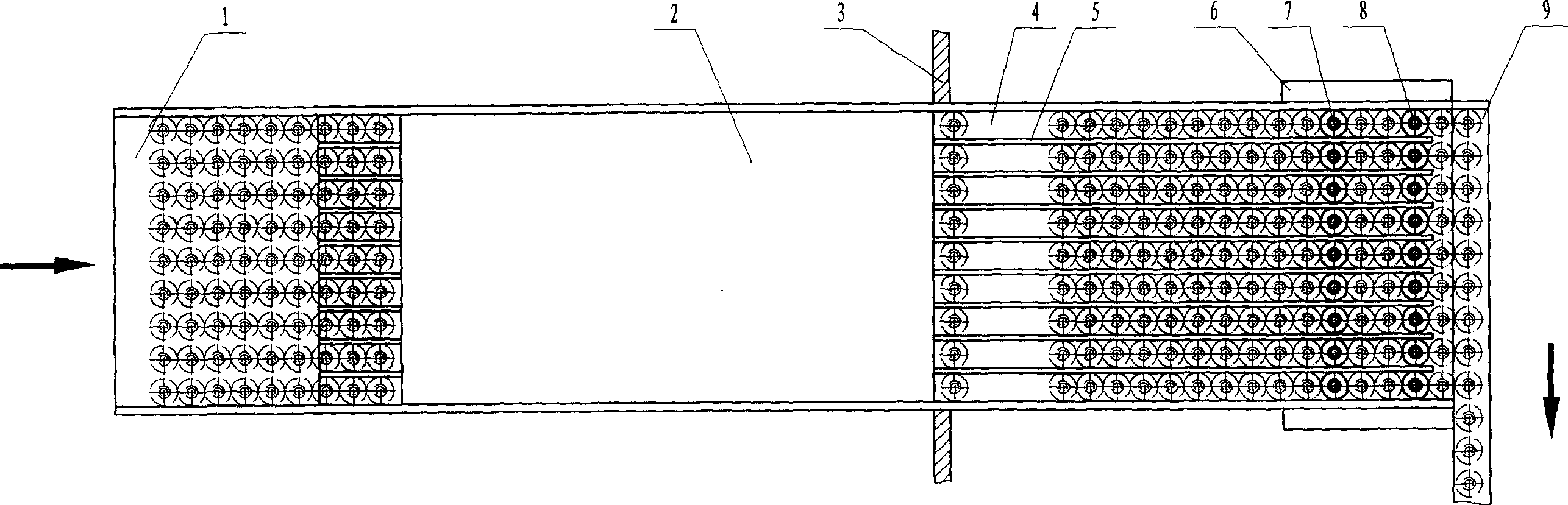

[0035] Embodiment 1: as figure 1 with figure 2 As shown, a cleaning, filling and corking device for a glass bottle or a similar container of the present invention includes a bottle feeding device 1, a bottle washing machine 2, a filling and stoppering machine 6 and a bottle output device 9 connected successively. In the example, the bottle feeding device is a bottle unscrambling conveying device, the bottle washing machine 2 adopts a box type bottle washing machine 2 (for example: QCX30 type box type bottle washing machine), and the bottle output device 9 is a single row bottle transporting track. The bottle unscrambling conveying device is connected with the bottle inlet mechanism in the bottle washing machine 2, and a multi-track conveying device 4 is arranged between the bottle washing machine 2 and the filling and stoppering machine 6, and one end of the multi-track conveying device 4 is connected to the outlet in the bottle washing machine 2 The bottle mechanism is conn...

Embodiment 2

[0039] Embodiment 2: as image 3 with Figure 4 As shown, a cleaning, filling and corking device for a glass bottle or a similar container of the present invention includes a bottle feeding device 1, a bottle washing machine 2, a filling and stoppering machine 6 and a bottle output device 9 connected successively. In the example, the bottle feeding device is a single row bottle feeding track, the bottle washing machine 2 adopts a box type bottle washing machine 2 (example: QCX30 type box type bottle washing machine), and the bottle output device 9 is a single row bottle feeding track. The single row bottle conveying track is connected with the bottle feeding mechanism in the bottle washing machine 2, and a multi-track conveying device 4 is arranged between the bottle washing machine 2 and the filling and stoppering machine 6, and one end of the multi-track conveying device 4 is connected to the outlet in the bottle washing machine 2. The bottle mechanism is connected, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com