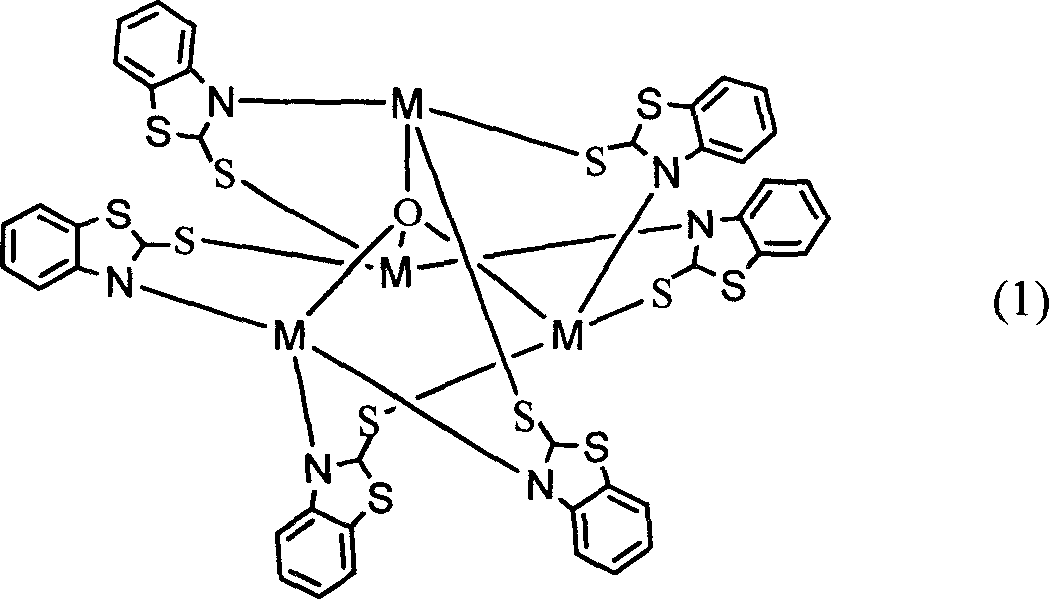

Process of preparing 2-thio benzothiazole transition metal cluster compound

A mercaptobenzothiazole and transition metal technology is applied in the field of preparing 2-mercaptobenzothiazole transition metal clusters, and can solve the problems of affecting application promotion, low solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Synthesis of 2-mercaptobenzothiazolium iron clusters

[0012] In a 250mL three-necked flask equipped with a thermometer, a reflux condenser and a stirring magnet, add 4.00g (0.024mol) of 2-mercaptobenzothiazole and 80mL of absolute ethanol, and stir to completely dissolve the solid. Then, 1.70 g (0.025 mol) of sodium ethoxide was added, and stirring was continued for 8 hours, followed by the dropwise addition of 50 mL of 30% FeSO 4 Aqueous solution, control the temperature of the system at reflux temperature, stir for 1 hour, a yellow-brown precipitate is formed, cool to room temperature, filter, wash the yellow-brown precipitate with water, and dry at a temperature lower than 100°C to obtain yellow-brown 2-mercaptobenzothiazole Iron cluster crystals, yield 3.08g (yield about 62.3%).

[0013] The physical and spectroscopic properties of the obtained compound are as follows:

[0014] Melting point: 273-275°C.

[0015] Elemental analysis: theoretical value C...

Embodiment 2

[0017] Example 2: Synthesis of 2-mercaptobenzothiazole cobalt clusters

[0018] In a 250mL three-necked flask equipped with a thermometer, a reflux condenser and a stirring magnet, add 4.00g (0.024mol) of 2-mercaptobenzothiazole and 80mL of absolute ethanol, and stir to completely dissolve the solid. Then, 1.70 g (0.025 mol) of sodium ethoxide was added, and stirring was continued for 7 hours, followed by the dropwise addition of 50 mL of 30% CoCl 2 Aqueous solution, control the temperature of the system at reflux temperature, stir for 1.5 hours to form a green precipitate, cool to room temperature, filter, wash the green precipitate with water, and dry it below 100°C to obtain a green 2-mercaptobenzothiazole cobalt cluster Compound crystals, yield 3.07g (yield about 61.4%).

[0019] The physical and spectroscopic properties of the obtained compound are as follows:

[0020] Melting point: 311-312°C.

[0021] Elemental analysis: theoretical value C 42 h 24 N 6 co 4 OS 1...

Embodiment 3

[0023] Embodiment 3: the synthesis of 2-mercaptobenzothiazole nickel cluster compound

[0024] In a 250mL three-necked flask equipped with a thermometer, a reflux condenser and a stirring magnet, add 4.00g (0.024mol) of 2-mercaptobenzothiazole and 80mL of absolute ethanol, and stir to completely dissolve the solid. Then, 1.70 g (0.025 mol) of sodium ethoxide was added, and stirring was continued for 7 hours, followed by the dropwise addition of 50 mL of 30% NiSO 4 Aqueous solution, control the temperature of the system at reflux temperature, stir for 1 hour, a purple precipitate is formed, cool to room temperature, filter, wash the purple precipitate with water, dry below 100°C, and obtain a purple 2-mercaptobenzothiazole nickel cluster Compound crystals, yield 3.16g (yield about 63.3%).

[0025] The physical and spectroscopic properties of the obtained compound are as follows:

[0026] Melting point: 332-334°C.

[0027] Elemental analysis: theoretical value C 42 h 24 N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com