Aqueous ink for mimeograph printing and method for mimeograph printing

A stencil printing, water-based technology, applied in the direction of ink, application, household utensils, etc., can solve problems such as damage, inability to print again, loss of ink fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

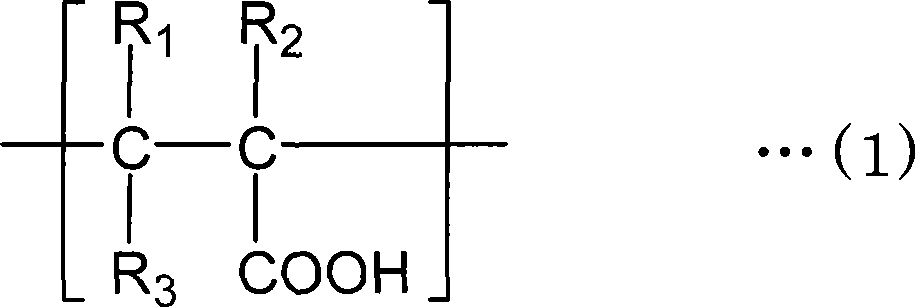

Method used

Image

Examples

Embodiment 1

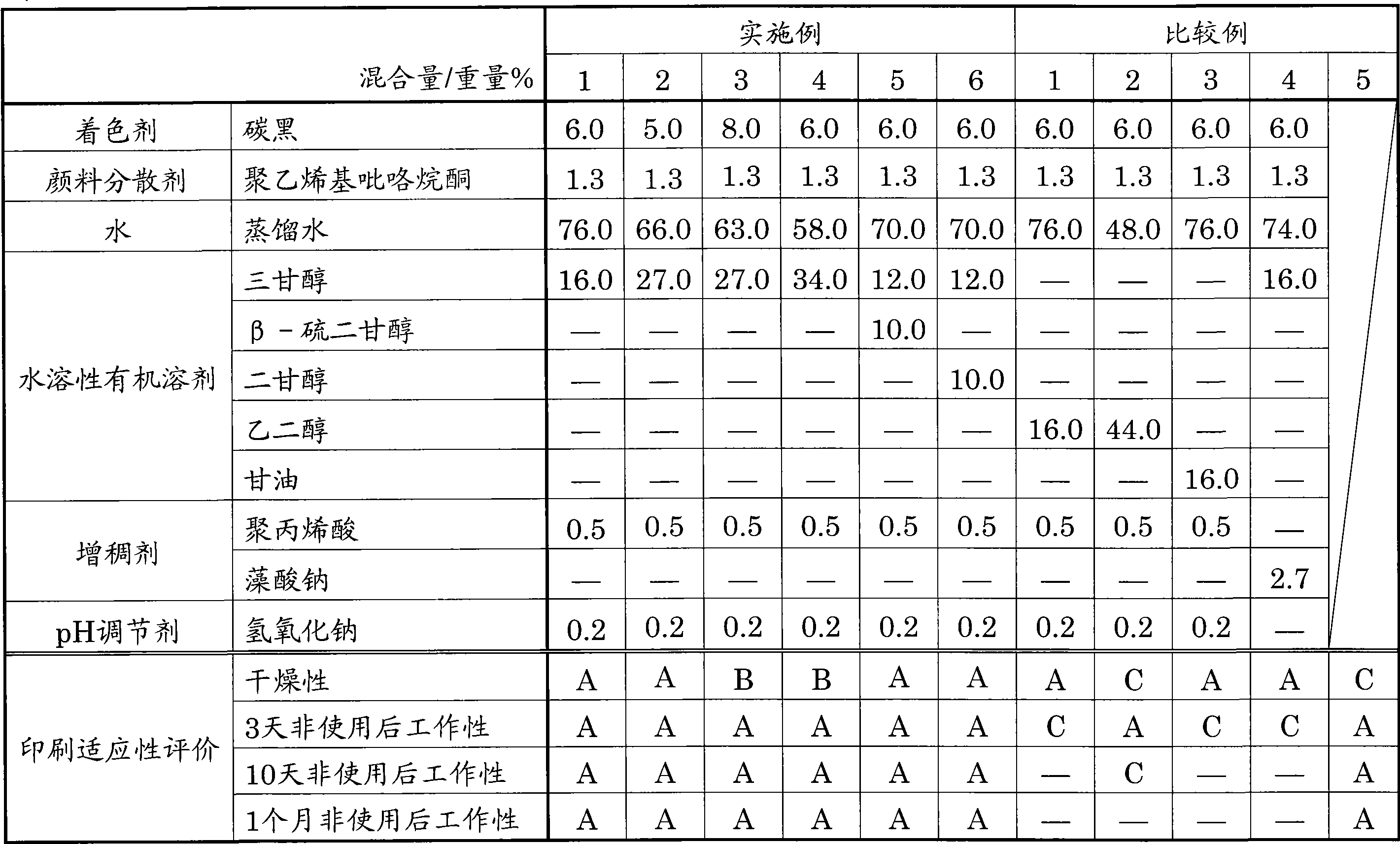

[0057]6.0% of carbon black ("MCF88" manufactured by Mitsubishi Chemical Corporation) as a colorant, 1.3% of polyvinylpyrrolidone ("K90" manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.) as a pigment dispersant, and 20.0% of distilled water were mixed, Fully disperse it with a sand mill to prepare a pigment dispersion. Dissolve 0.5% of polyacrylic acid ("Junlon PW 150" manufactured by Nippon Junyaku Co., Ltd.) as a thickener in 16.0% of distilled water, add 10.0% of 2% sodium hydroxide aqueous solution to this for neutralization, and then add the previously prepared The pigment dispersion, 16.0% of triethylene glycol, and the remainder (30.2%) of distilled water were mixed to obtain the ink of Example 1.

[0058] Embodiment 2~6, comparative example 1~4

[0059] Except for the formulation shown in Table 1, it carried out similarly to Example 1, and obtained the ink of each Example and a comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com