Method for making spring shaft mounted in eyeglass elastic hinge

A technology of elastic hinges and manufacturing methods, which is applied in glasses/goggles, optics, instruments, etc., can solve problems such as large diameter errors, deformation of hinge holes, and product performance degradation, and achieve long service life, tight fit, and good performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

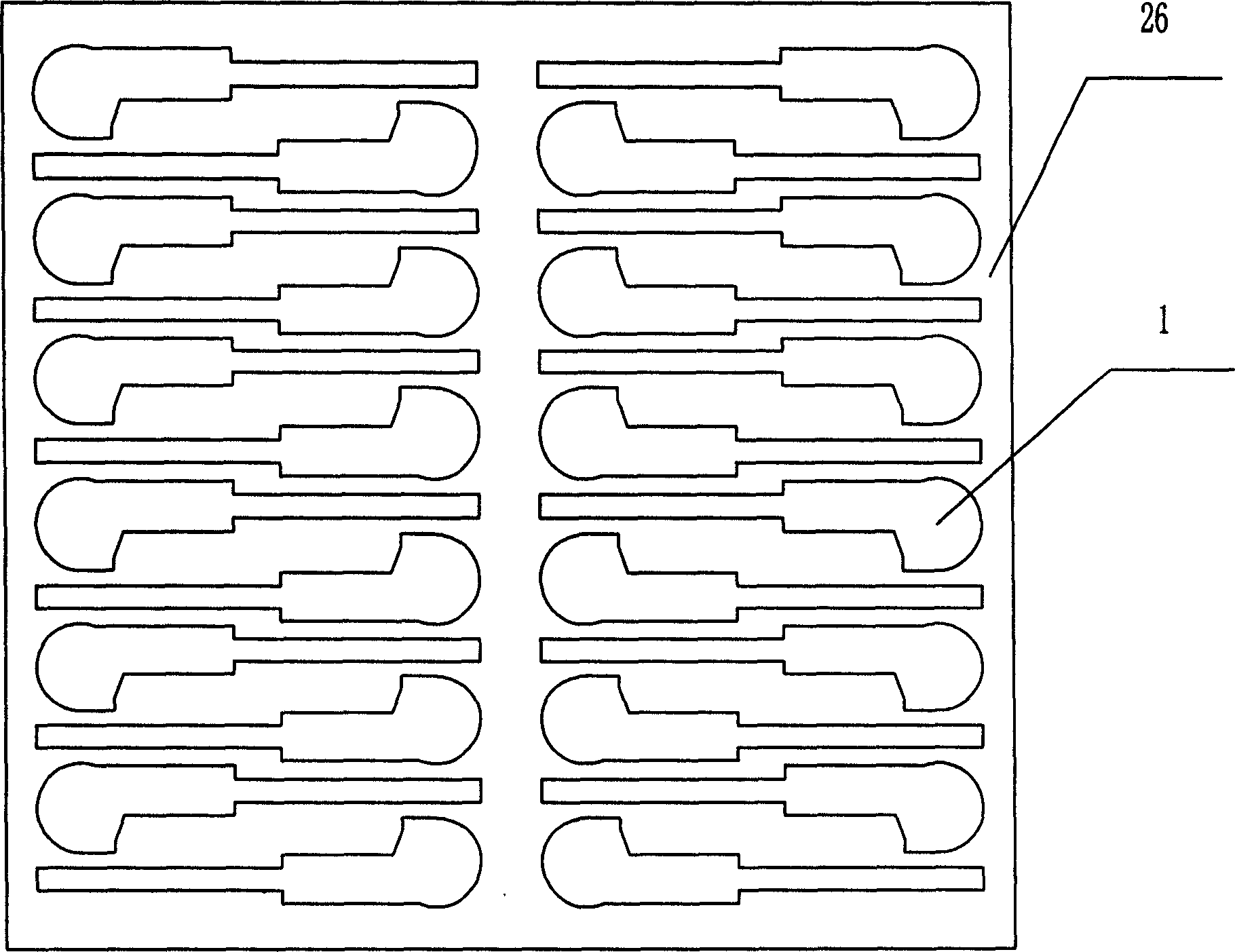

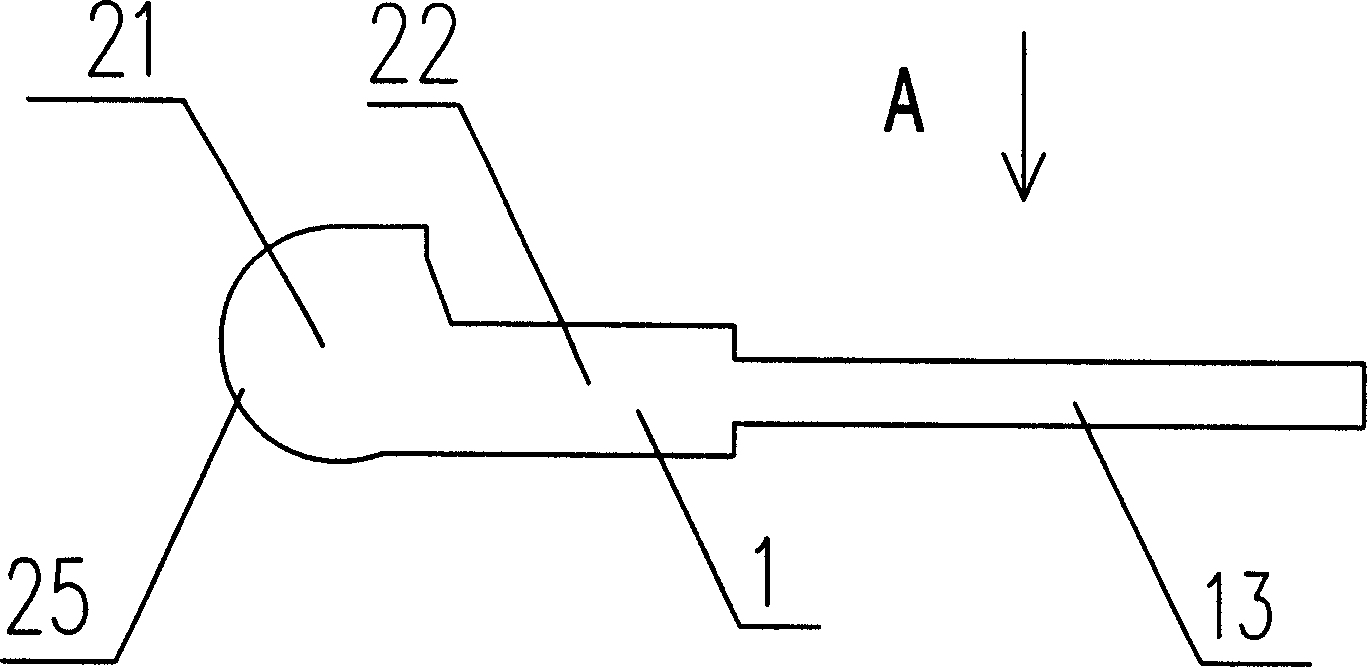

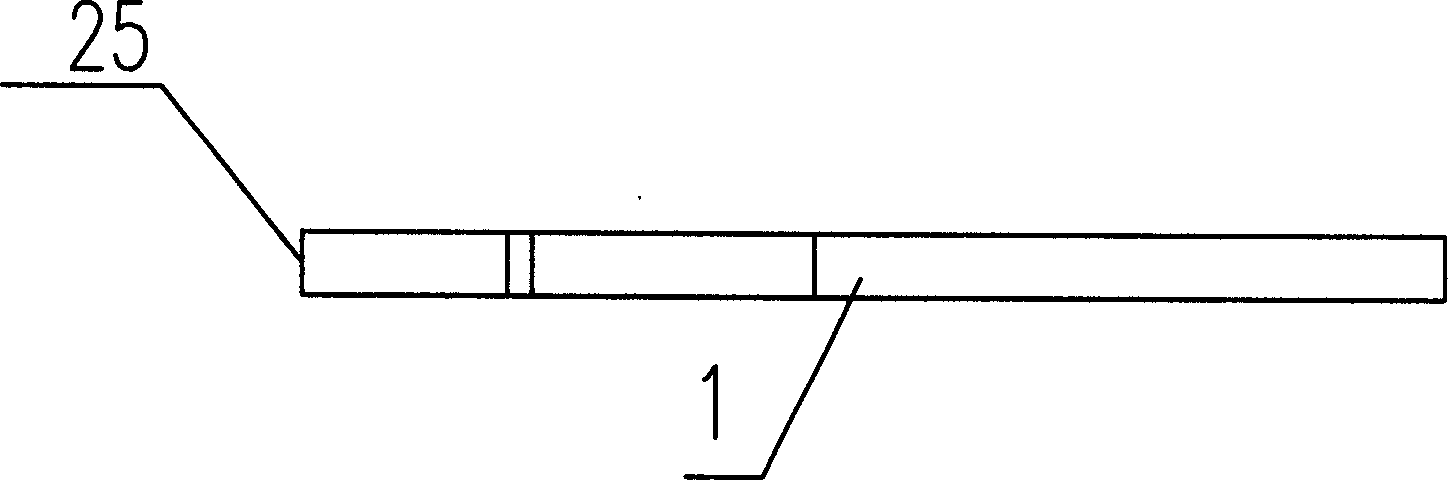

[0028] As shown in the figure, a metal material plate 26 with a high material utilization rate is prepared. The single-process blanking die and the feeder are installed on the blanking machine, and then the blank of the hinge shaft 1 is punched out from the metal plate 26 along the closed contour at one time, so that the shape of the blank is the same as the finished hinge shaft, except for the tail. 13 has not yet been formed, at this time the tail 13 is in the shape of a square column, the head 21 and the body 22 have been formed at one time, and the surface of the shearing surface 25 has no traces of multiple punching. Then use ordinary metal cutting machine tools, such as small bench drills and instrument milling with a drill die, and then use the good drilling performance of the drill bit to drill the hinge hole 20 that meets the technical require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com