Cooling water-tower sprinkling plate structure

A technology for cooling water towers and sprinkler trays, which is applied to water shower coolers, direct contact heat exchangers, heat exchanger types, etc., and can solve the problems of reducing water consumption recovery rate, increasing electricity cost, and discounting the effect of hot water cooling to reduce congestion, save water and electricity costs, and improve industrial competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

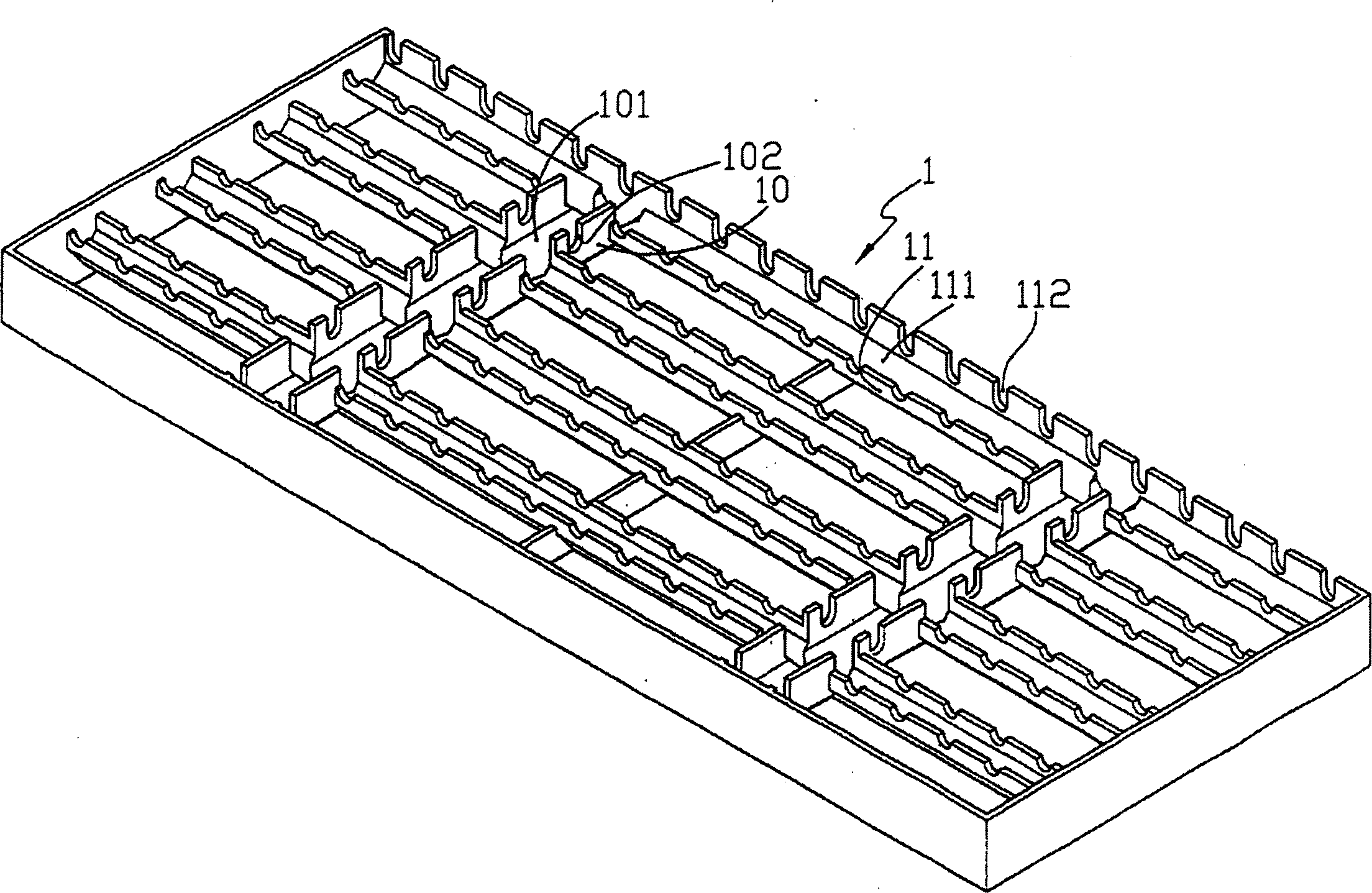

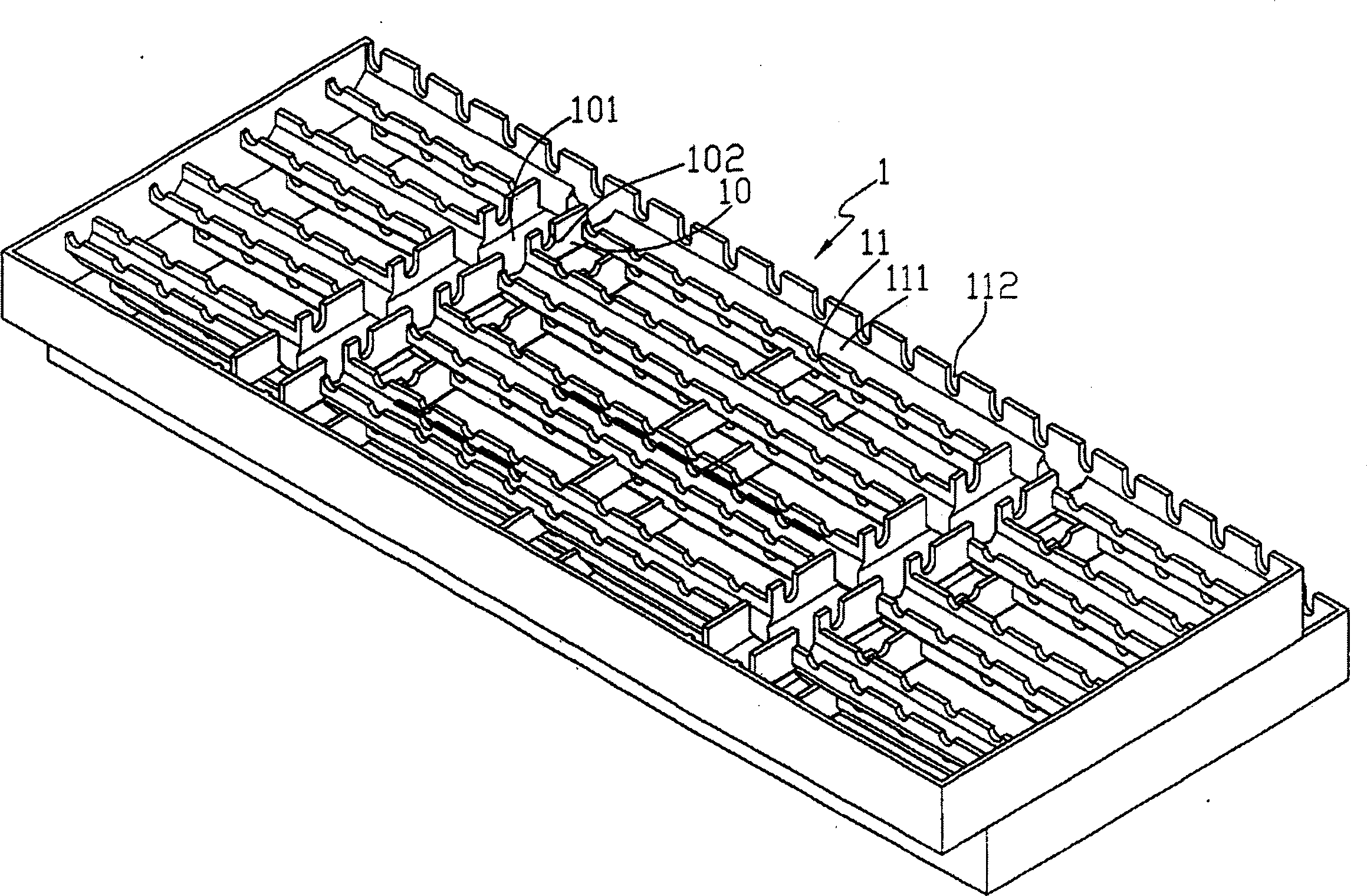

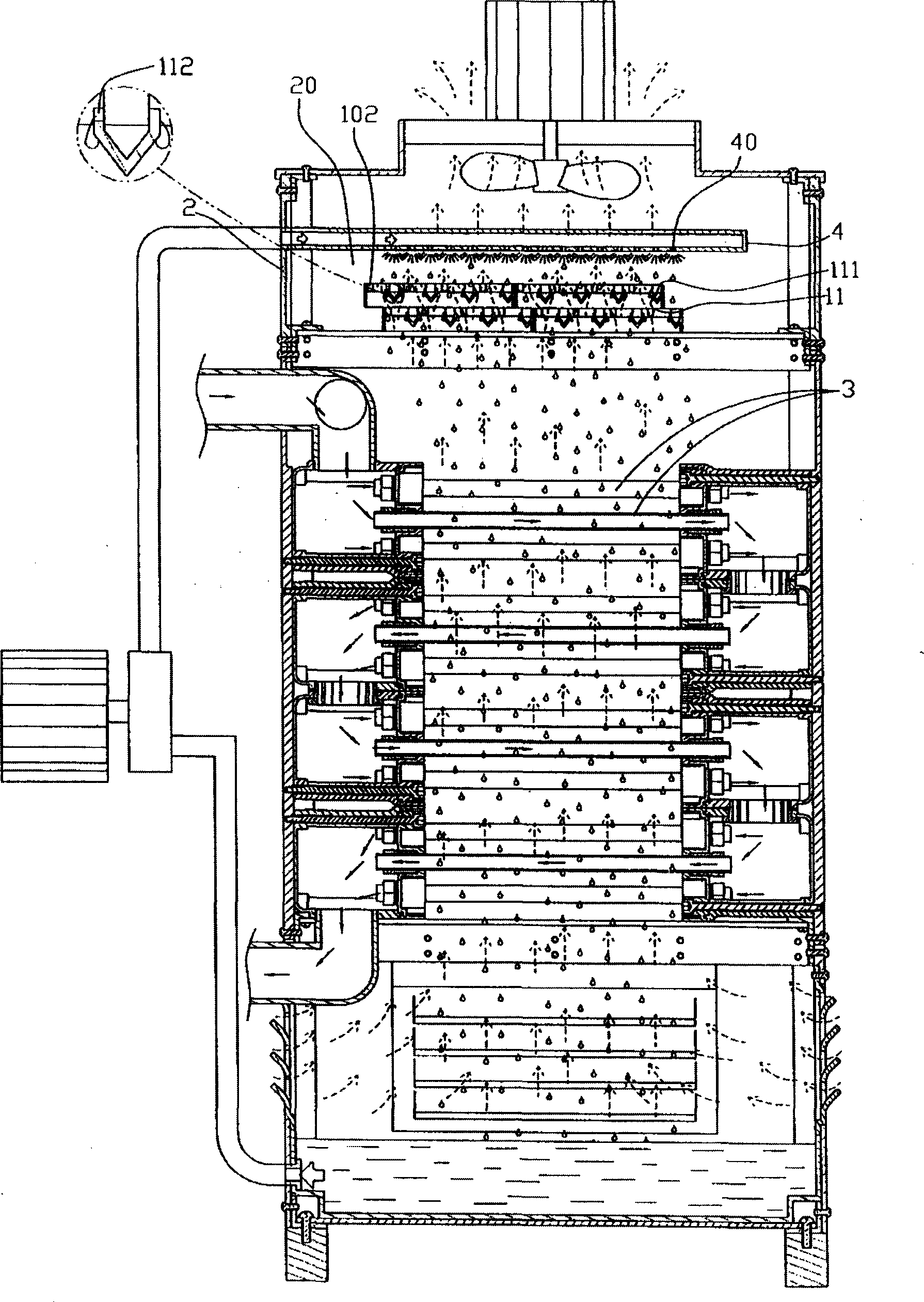

[0019] refer to Figure 1 to Figure 4 , a cooling tower sprinkler plate structure of the present invention, which mainly includes a plate body 1, which can be composed of several longitudinal ribs 10, or composed of several transverse ribs 11, or composed of several longitudinal ribs 10 and transverse ribs 11 are composed of each other, and the two adjacent longitudinal ribs 10 are parallel, or the two adjacent transverse ribs 11 are parallel, or the longitudinal ribs 10 and transverse ribs 11 are interlaced. ; Moreover, flow channels 101, 111 can be provided inside the above-mentioned ribs 10, 11, and gaps 102, 112 are provided on the peripheral sides of the flow channels 101, 111, so that cooling water drips on the flow channels 101, 111 of the tray body 1 After the internal assembly, it can overflow from the gaps 102, 112 to the outside.

[0020] When in use, it is only necessary to stack the two trays 1 on top of each other and then install them at an appropriate place ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com