Mechanical automatic speed transmission

An automatic transmission and mechanical technology, applied in the field of mechanical transmission, can solve the problems of poor maintainability and assembly, high labor intensity, frequent operation, etc., and achieve the effects of convenient maintenance, reduced labor intensity, and convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

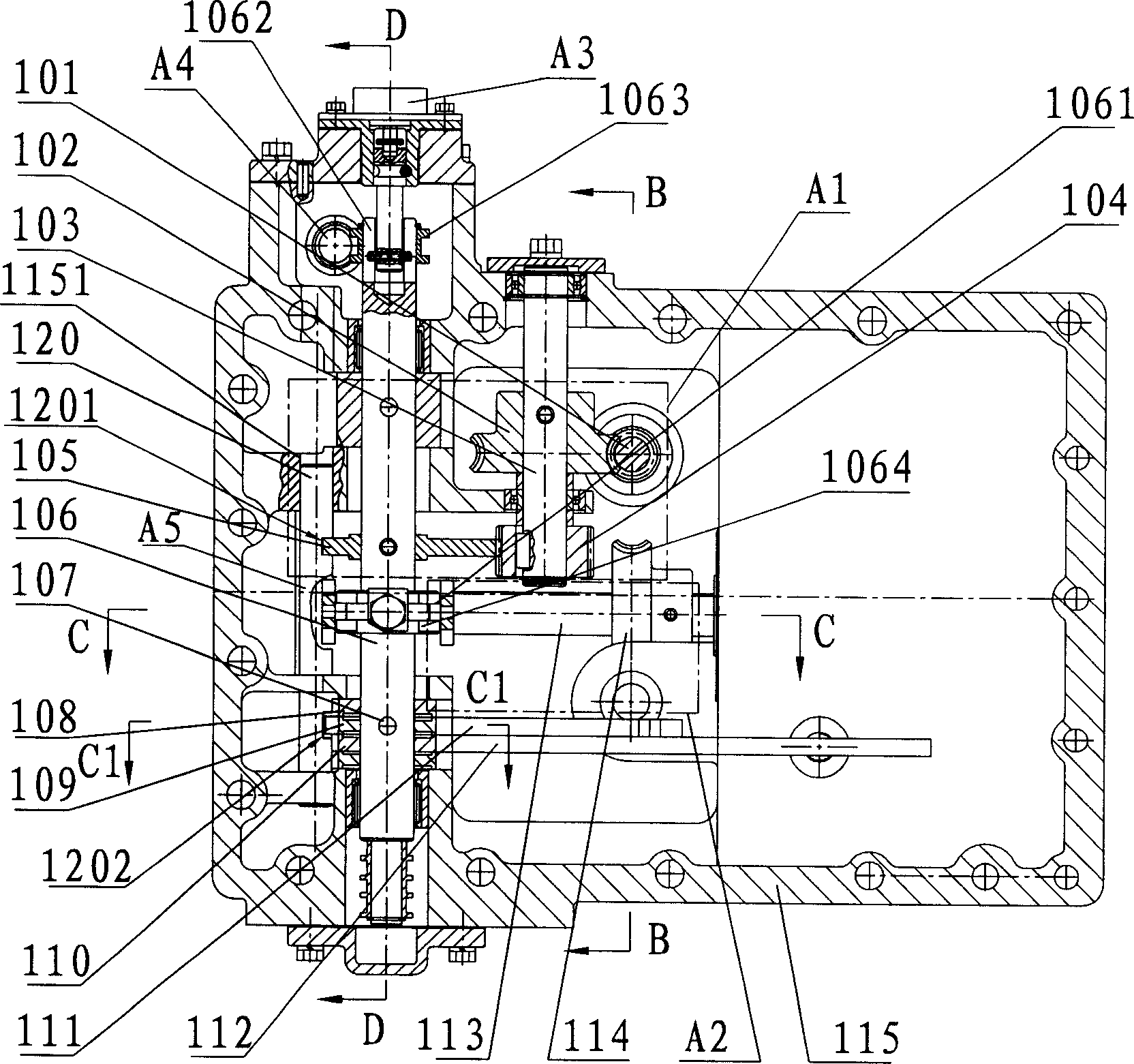

[0030] Taking the transmission of six gears as an example below, the present invention will be further described. Wherein the intermediate gear shifting block and the intermediate gear connecting rod have only one piece each, which are respectively two / three speed shifting blocks 109 and two / three speed connecting rods 111.

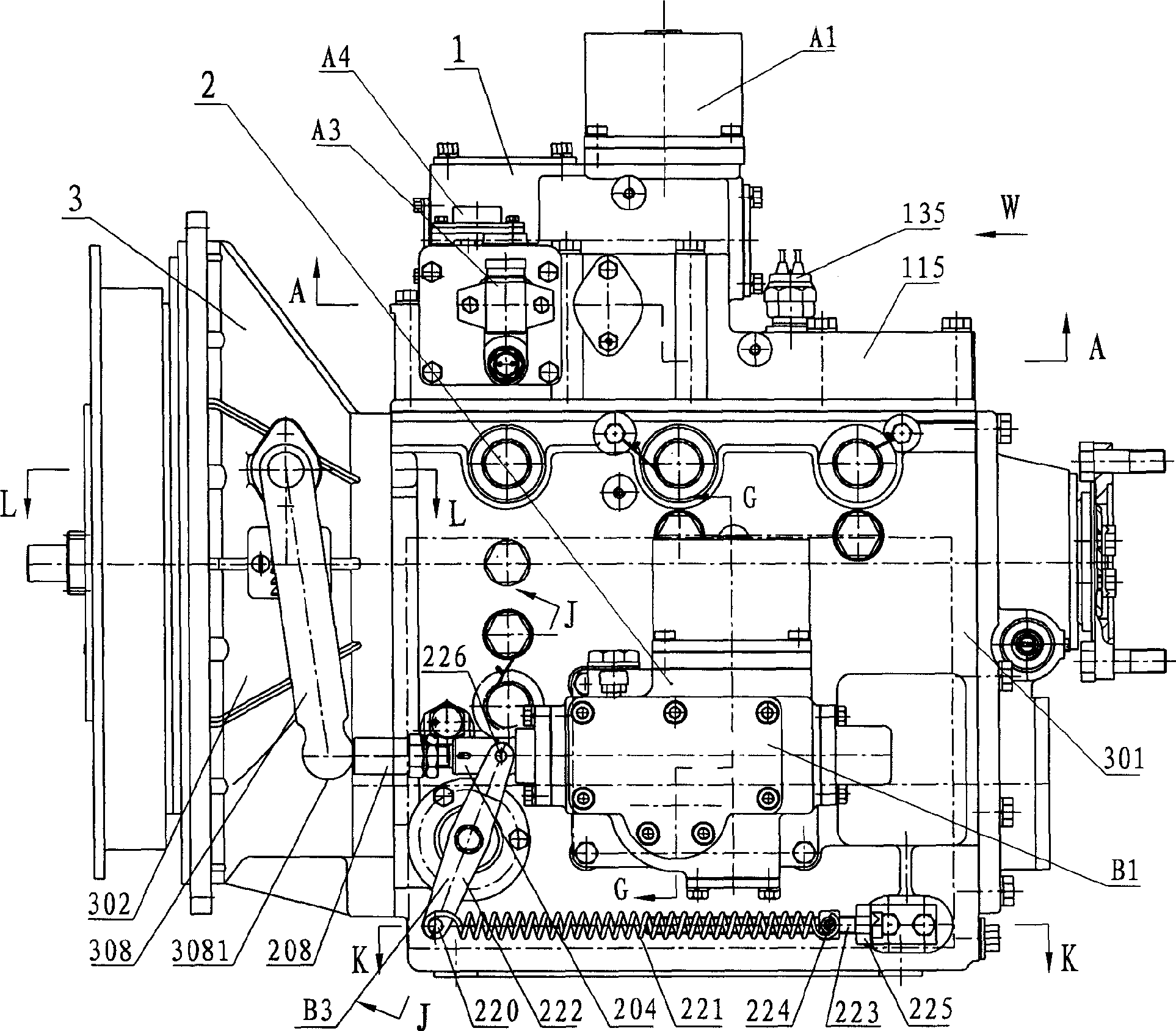

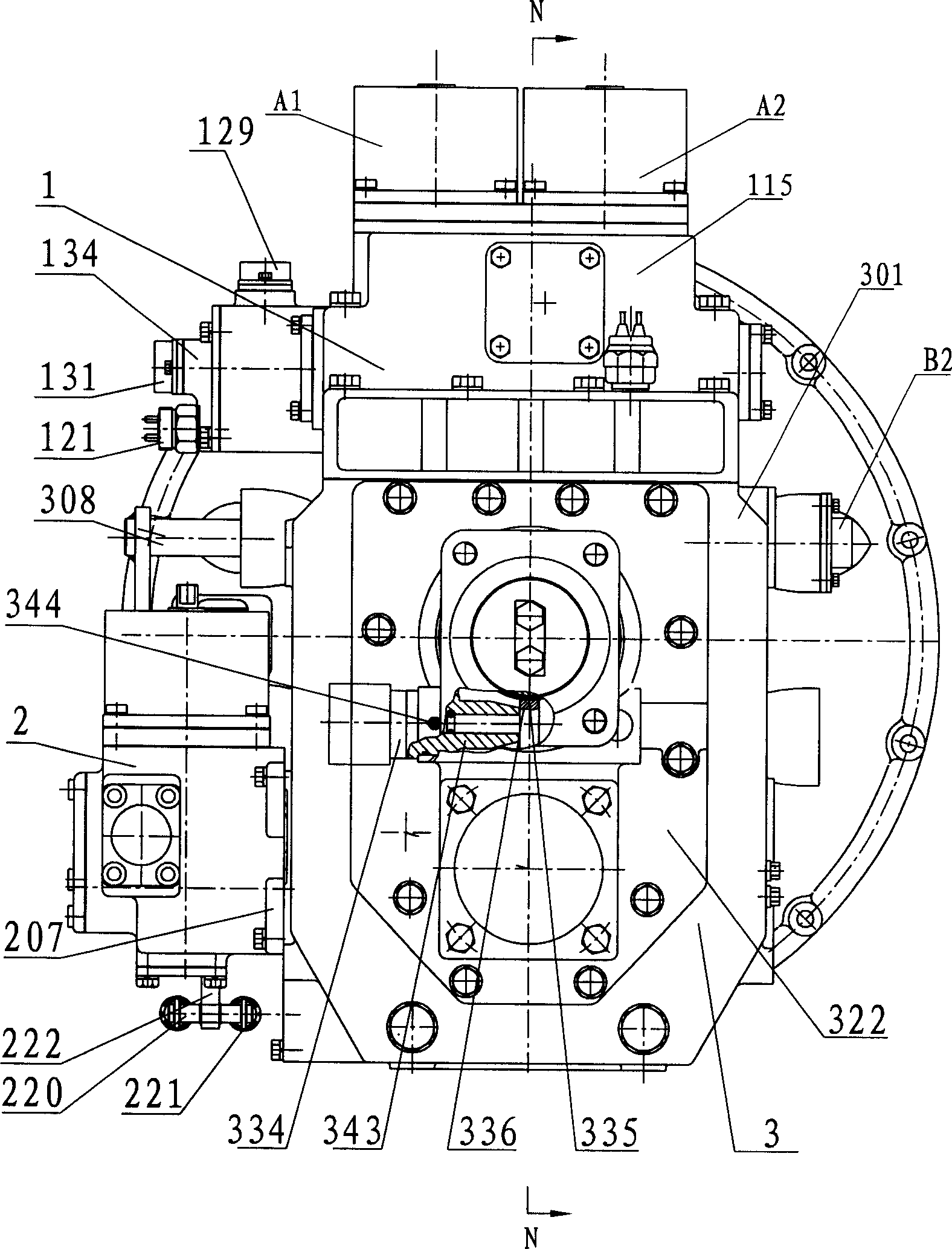

[0031] Such as figure 1 , 2, 20, the mechanical automatic transmission of the present invention includes: a speed change transmission device 3, a shift actuator 1 and a clutch actuator 2. Such as figure 2 , 15 As shown in -19, the speed change transmission device 3 mainly includes a main housing 301, a clutch housing 302, a release bearing seat 303, a clutch release bearing 304, an input shaft 305, a clutch 306, a release shift fork 307, a release bearing control rod 308, a high-speed synchronization Device 309, high-speed shift fork 311, two / three-speed shift fork 313, two / three-speed synchronizer 314, low-speed shift fork 317, low-speed synchronize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com