Triangular rotor hydraulic pump

A triangular, hydraulic pump technology, applied in the field of rotor hydraulic pumps, can solve the problems of poor self-priming ability and oil pollution sensitivity of vane pumps, and achieve the effects of stable rotation, strong self-priming ability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

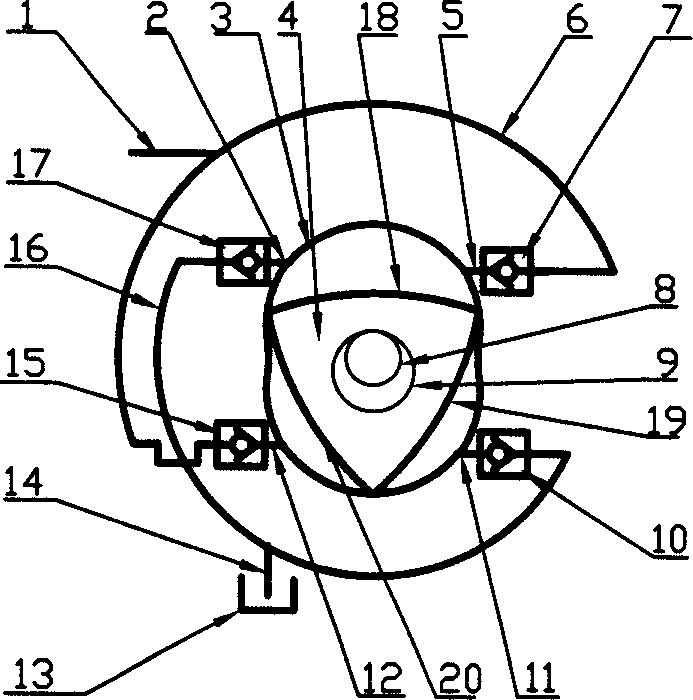

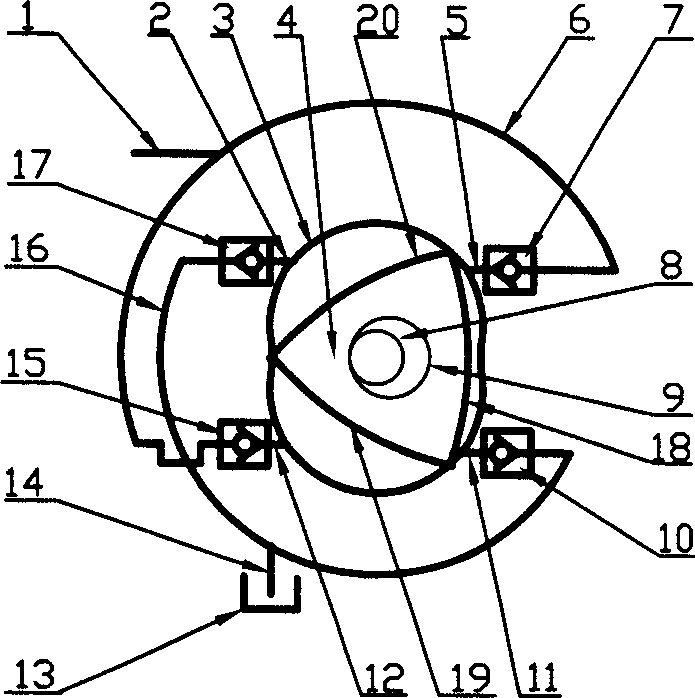

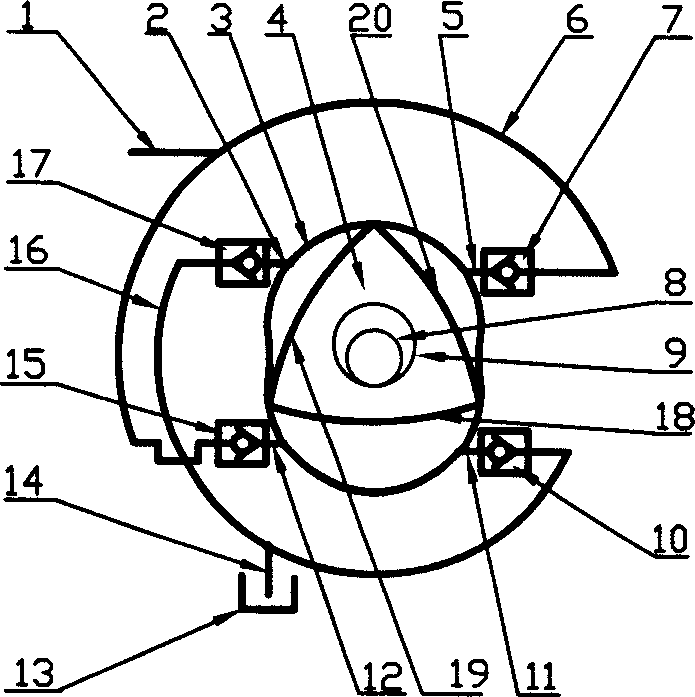

[0011] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the present invention is composed of a stator 3 and a rotor 4, the inner cavity of the stator 3 is an "8"-shaped hysteroidal curve surface, and an oil inlet 2, an oil inlet 11, an oil outlet 5 and an oil outlet 12 are opened on it. . The oil inlets 2 and 11 are connected to the oil inlet groove 16 through the oil inlet check valves 17 and 10 respectively, and the oil suction port 14 on the oil inlet groove 16 communicates with the oil tank 13 . The oil outlets 5 and 12 are respectively connected to the oil outlet 6 through the check valve oil outlets 7 and 15, and the oil outlet 6 communicates with the pressure oil port 1. The oil inlet groove 16 and the oil outlet groove 6 are not communicated with each other, and each constitutes an independent passage. The rotor 4 is in the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com