Device for guiding, conveying, or treating a fiber cable

A fiber rope and equipment technology, applied in the direction of drafting equipment, fiber processing, thin material processing, etc., can solve problems such as different loads, achieve the effect of reducing fiber transmission, reducing risks, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

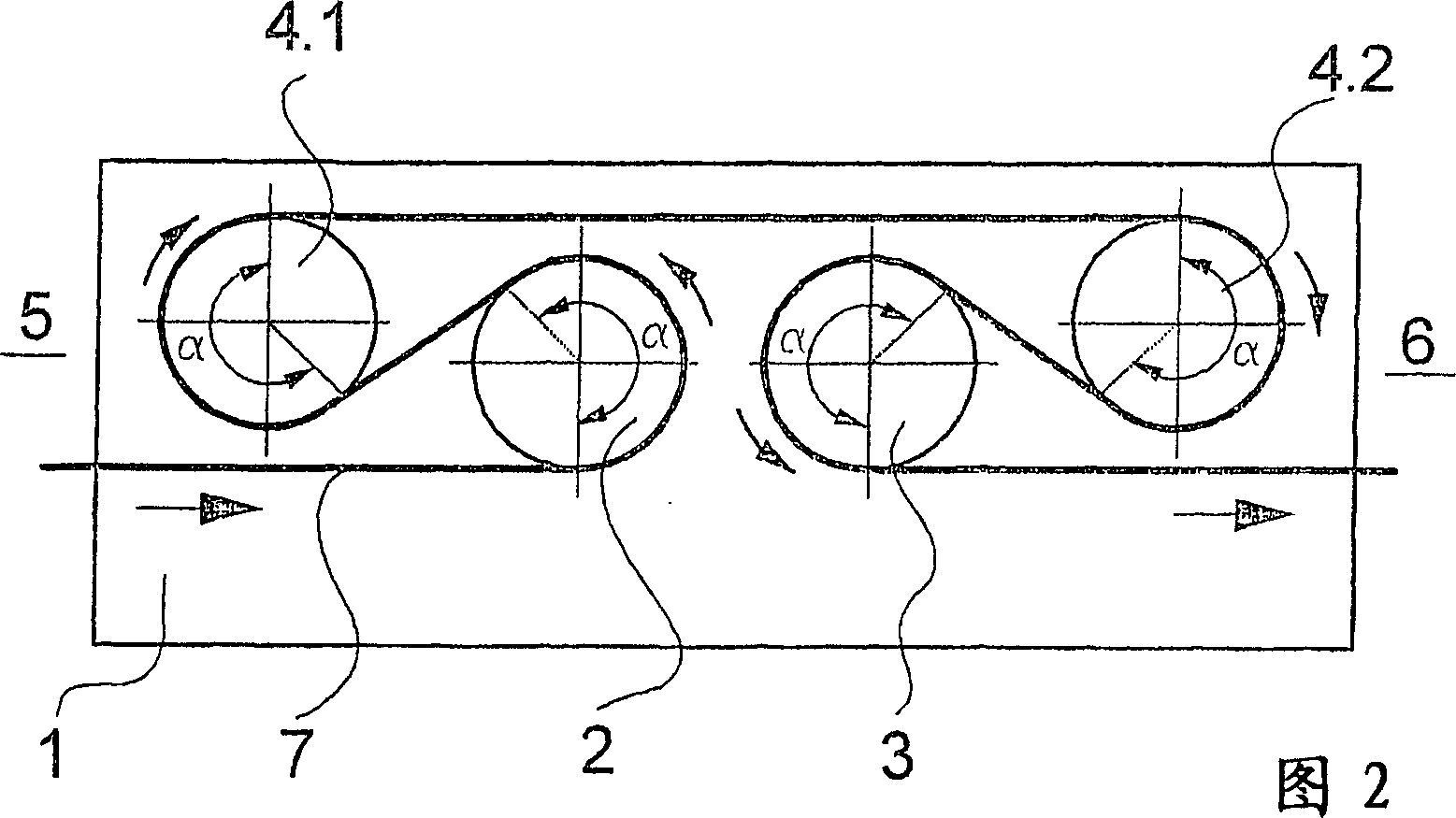

[0027] 1 and 2 schematically show a first embodiment of the device according to the invention. FIG. 1 shows a top view of this embodiment without a guided fiber cable, and FIG. 2 shows a side view of this embodiment with a guided fiber cable. The following description applies to both figures unless it is clearly indicated which figure.

[0028] The input roller 2 , the output roller 3 and the rollers 4 . 1 and 4 . 2 are arranged side by side on the support wall 1 . The rollers 2, 3, 4.1 and 4.2 are of identical construction and are held rotatably on the support wall 1 with a drive end. The rollers 2 , 3 , 4.1 and 4.2 are each coupled with their drive ends to a drive motor 8 . Each drive motor 8 is associated with an inverter 9 by which the drive motor 8 can be controlled.

[0029] The arrangement of the feed roller 2 , the discharge roller 3 and the rollers 4 . 1 and 4 . 2 is selected in such a way that the rollers 4 . 1 and 4 . 2 are held on the support wall 1 at a large d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com