Elevator apparatus

A technology for elevators and braking devices, which is applied to elevators, transportation and packaging in buildings, etc., can solve the problems of increased hoistway space, difficult maintenance and inspection operations, and increased axial length, so as to reduce installation space and maintain maintenance. Check the effect of easy work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

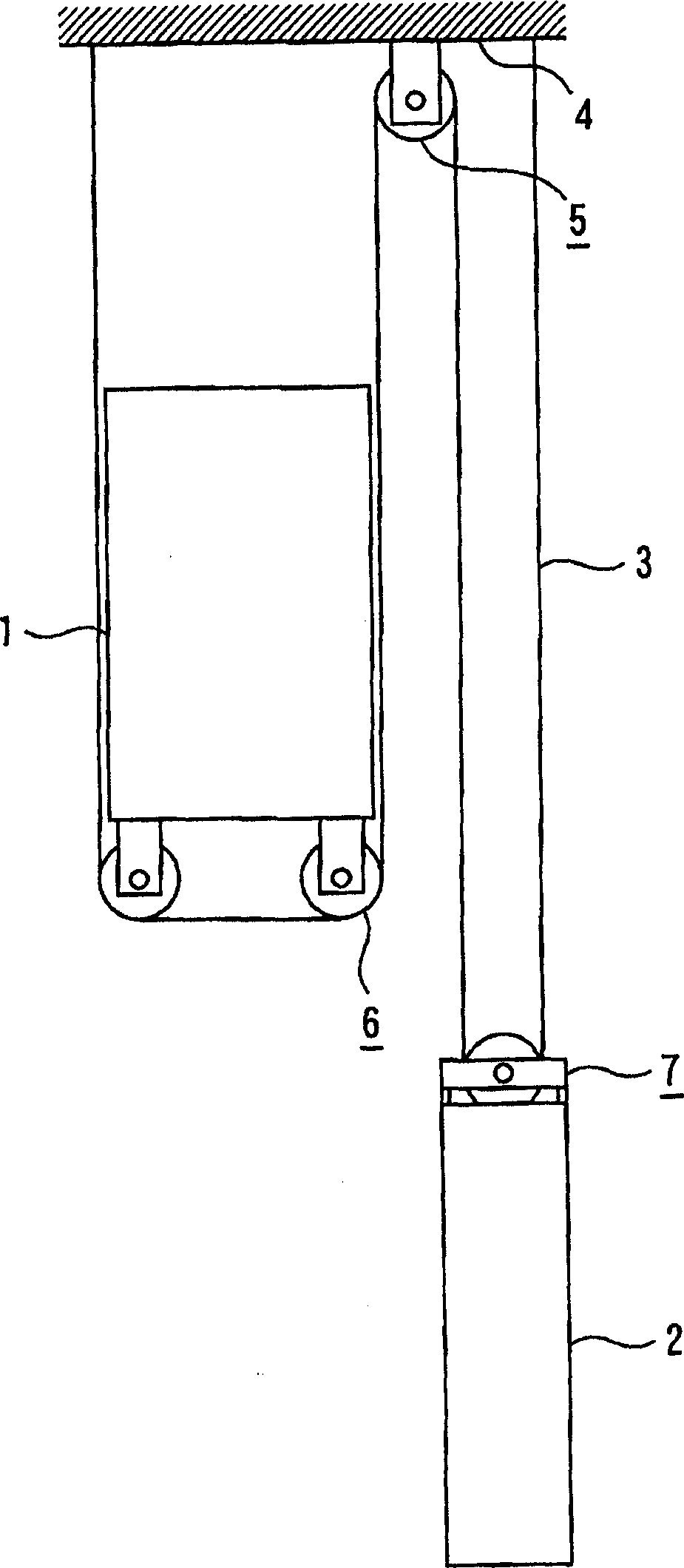

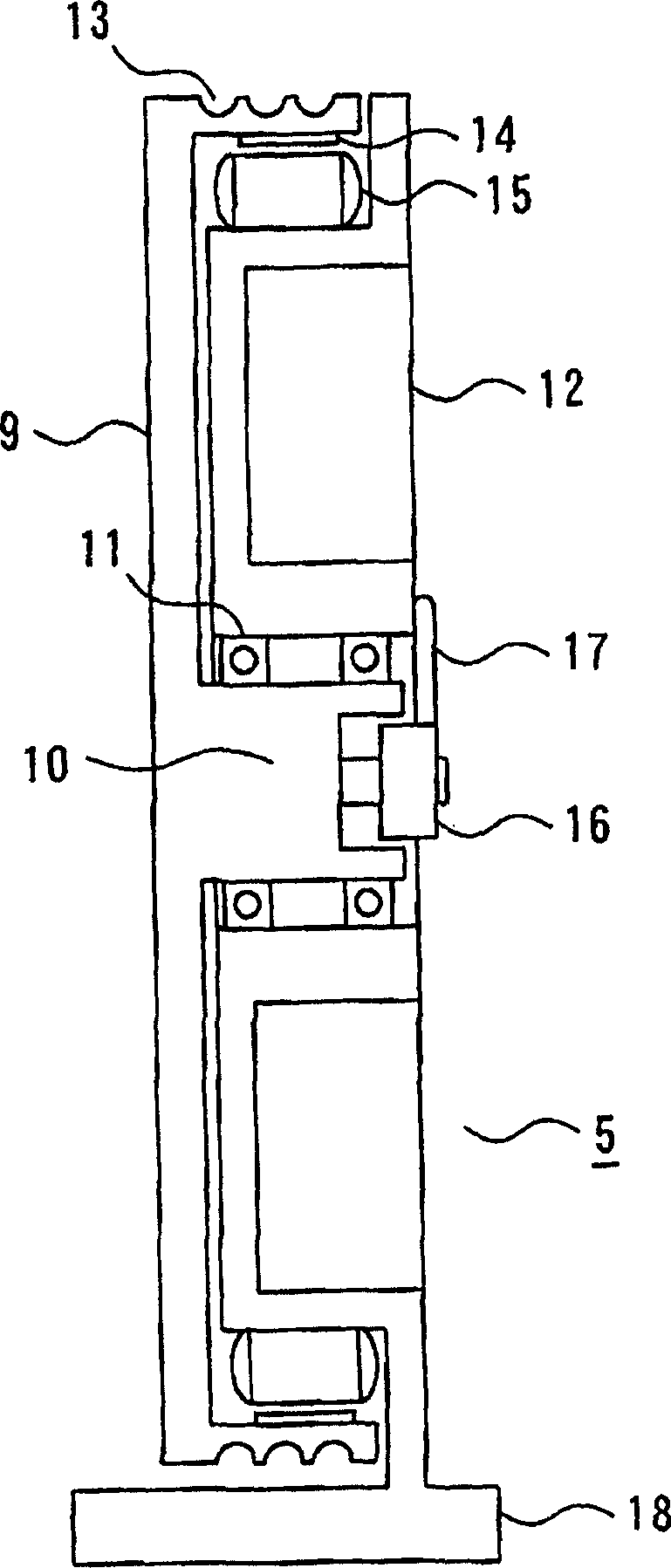

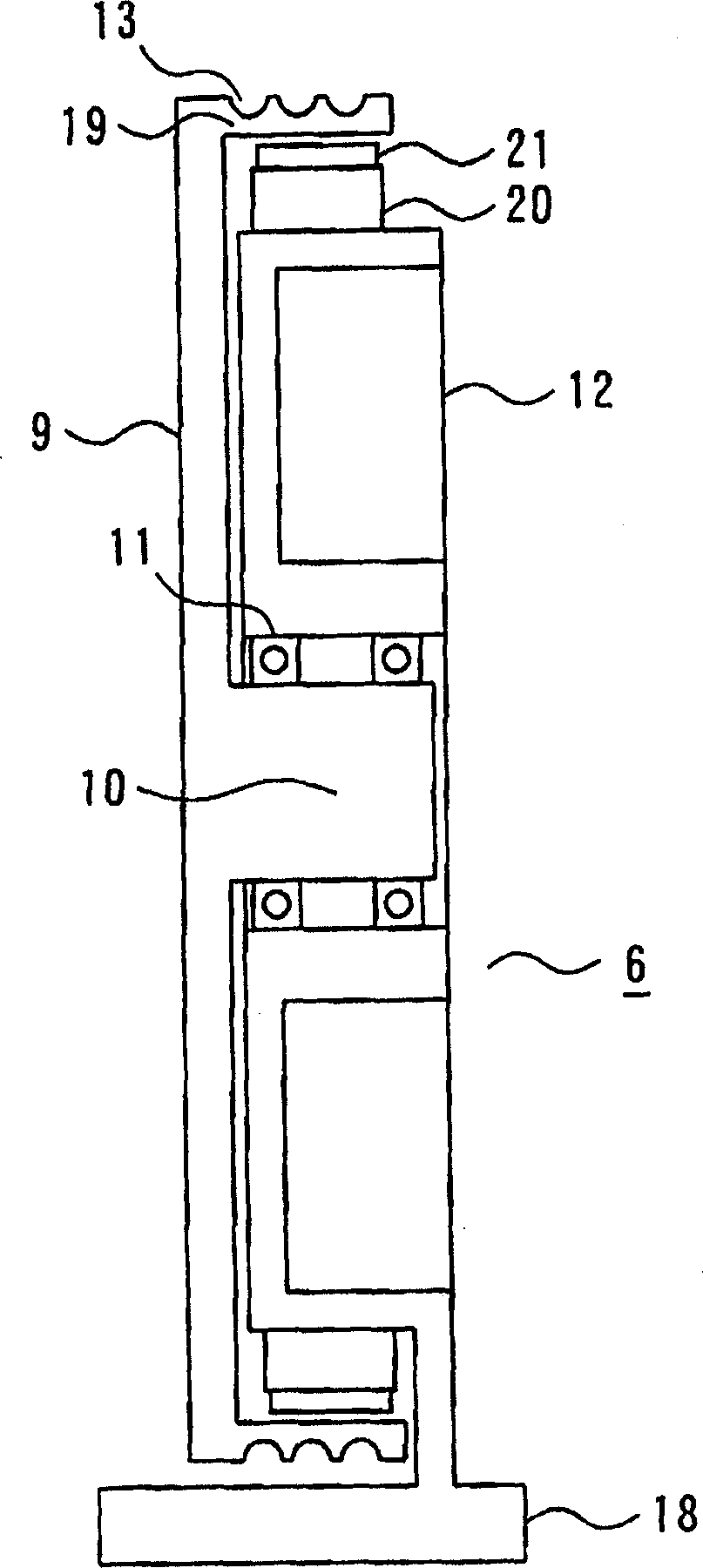

[0027] figure 1 It is a side view showing the overall conceptual structure of the elevator apparatus according to Embodiment 1 of the present invention; figure 2 It is a cross-sectional view showing the structure of the upper anti-sheave of the elevator device according to Embodiment 1 of the present invention, in which the driving device of the traction machine is installed; image 3 It is a cross-sectional view showing the structure of the car-side suspension sheave on which the first braking device of the traction machine is installed in the elevator apparatus according to Embodiment 1 of the present invention; Figure 4 It is a cross-sectional view showing the counterweight side suspension sheave of the second braking device of the traction machine installed in the elevator apparatus according to Embodiment 1 of the present invention; Figure 5 Yes means that there will be installed Figure 4 It is a side view of the state that the suspension wheel on the counterweight ...

Embodiment 2

[0037] Figure 6 It is a sectional view showing a car-side suspension sheave to which a first brake device and a second brake device of a hoisting machine are mounted in an elevator apparatus according to Embodiment 2 of the present invention.

[0038] exist Figure 6 Among them, the car side hanging wheel 6 in Embodiment 2 includes: a rotating body 9; a main shaft 10, which is integrally arranged at the central part of the rotating body 9; a base body 12, on which a bearing 11 is pivotally mounted The rotating body 9 and the main shaft 10; the sheave 13, which is arranged on the outer surface of the outer peripheral portion of the rotating body 9, and is wound with the main rope 3; the braking surface 19, which is formed on the inner surface of the outer peripheral portion of the rotating body 9 the first brake 20, which is arranged on the outer periphery of the base body 12; the first brake member 21, which is arranged on the outer side of the first brake 20, and is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com