Gate trolley

A trolley and door-type technology, which is applied in the petroleum industry, coke ovens, charging/unloading combined devices, etc., can solve the problems of high mobile machine prices, cumbersome maintenance and inspection, and reduced layout freedom, so as to achieve maintenance and inspection Ease of operation, simplification of operation control, and simplification of the driving mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

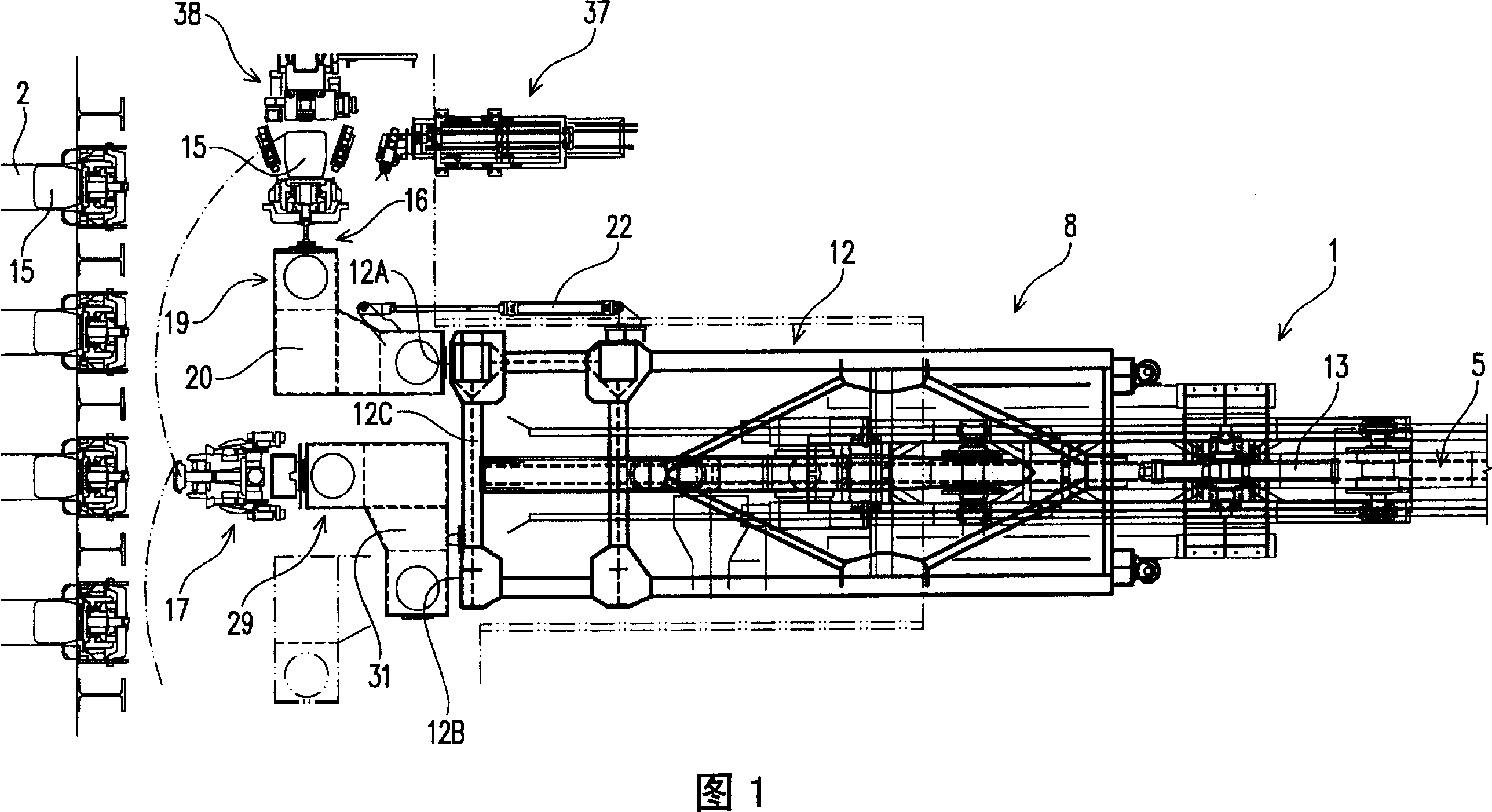

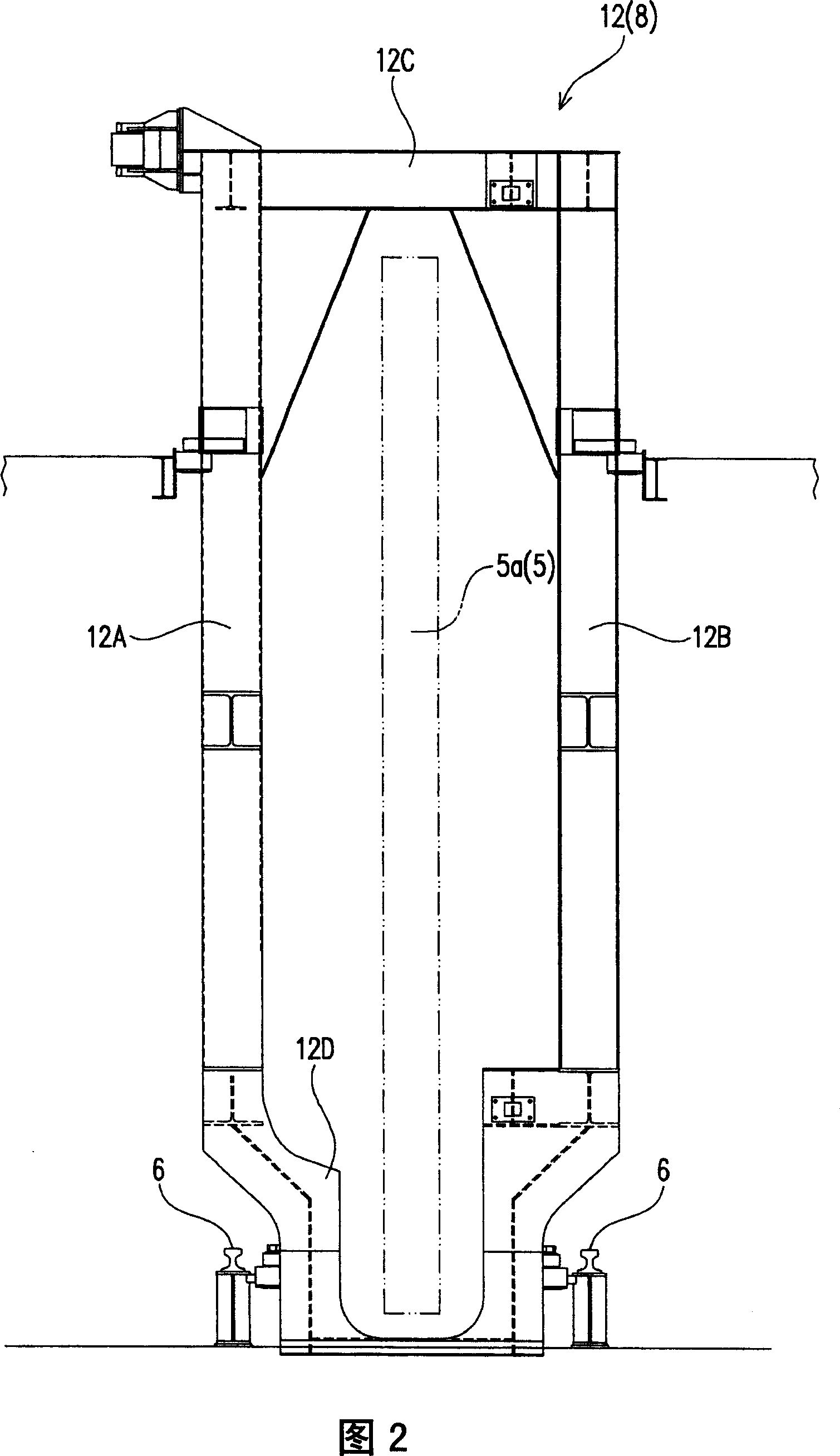

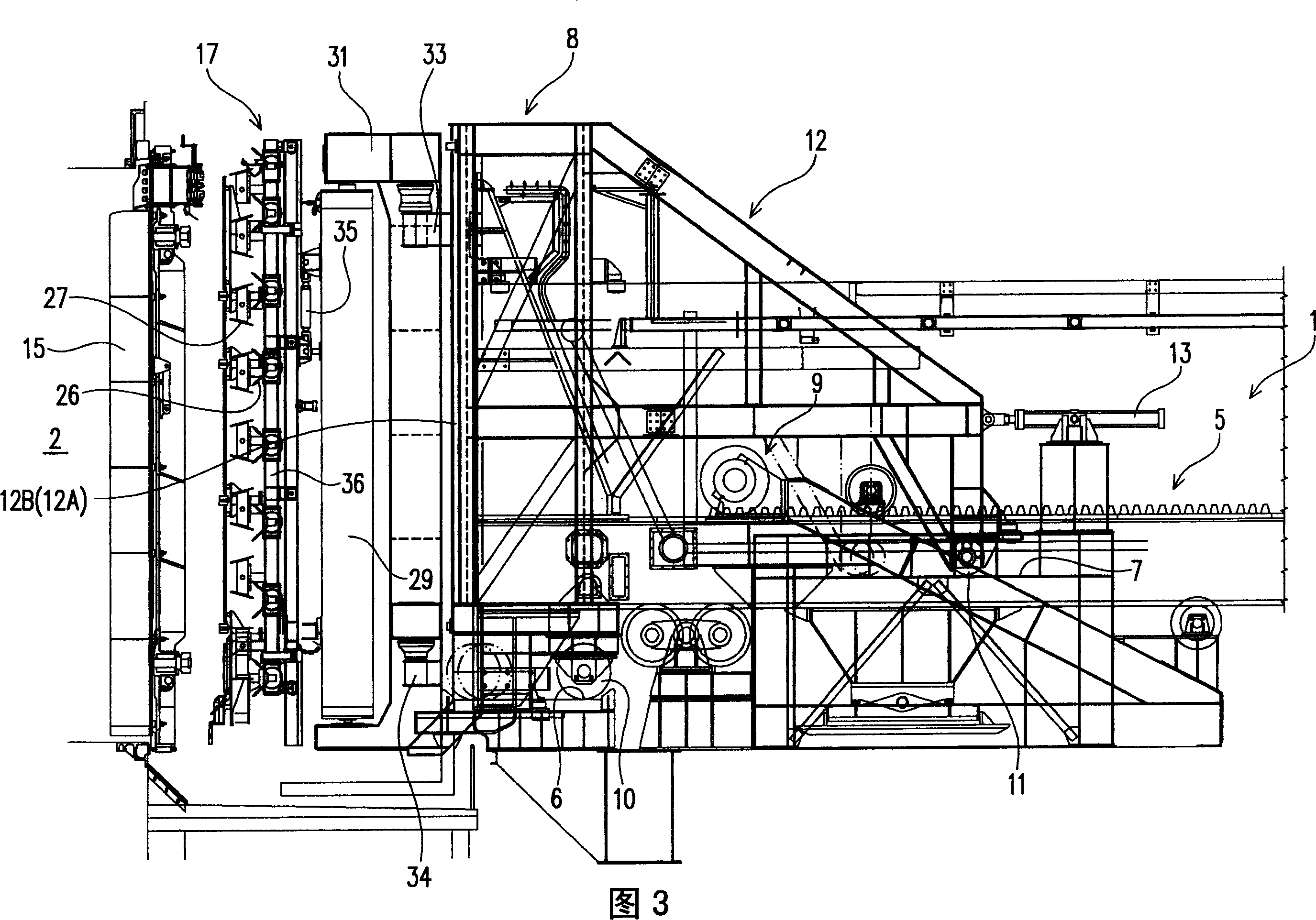

[0024] Hereinafter, with reference to the respective drawings, the case where the gantry trolley of the best embodiment of the present invention is mounted on a coke pushing machine and a coke guide car will be described in detail.

[0025] (Coke ejector)

[0026] Figure 1 is a plan view of the portal trolley, Figure 2 is a front view of the main body frame, Figure 3 is a side view of the portal trolley, Figure 4 is a front view of the coke ejector (mobile machine of the present invention), and Figure 5 is The side view of the coke pushing machine, and Figure 6 is its top view. As shown in these figures, the coke ejector 1 is installed freely on rails 3 and 4 laid on the ground along the direction of the furnace chamber 2 of the coke oven (refer to FIG. 5). A push rod 5 that pushes out the coke generated in the furnace chamber 2 freely advances and retreats, and the machine body has a track 6 and 7 laid at different heights in the direction intersecting (vertical) with the tracks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com