Double-vibrating mode driving piezoelectric ceramic ultrasound wave electric machine small wave differential controlling method

A technology of ultrasonic motors and piezoelectric ceramics, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Unable to achieve fast and accurate positioning and other problems, to achieve the effect of stable operation and easy open-loop control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

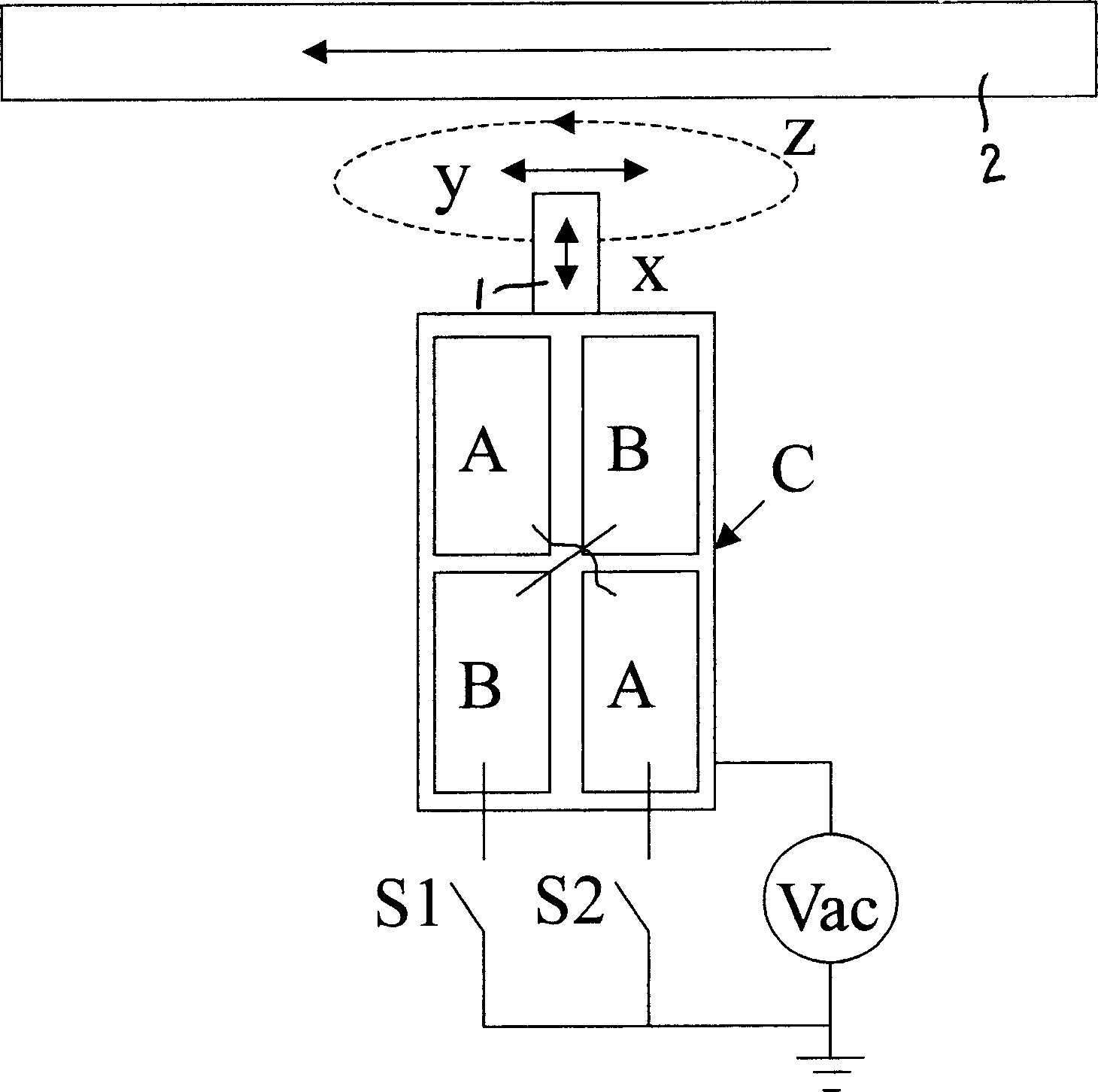

[0019] see figure 1 , A, B, and C are the three electrodes of the piezoelectric ceramic ultrasonic motor driven by dual vibration modes, where A, C form one set of electrodes, and B, C form another set of electrodes; x is the first-order longitudinal vibration mode , y is the first-order bending vibration mode, z is the elliptical motion trajectory of the driving head 1 composed of the first-order longitudinal vibration mode and the first-order bending vibration mode.

[0020] In the prior art, the sinusoidal voltage Vac of 39.6KHz is applied to the A, C electrodes or B, C electrodes respectively through the S1 and S2 direction switching switches to control the movement direction of the slider 2; and the movement speed of the slider 2 It is realized by controlling the size of Vac.

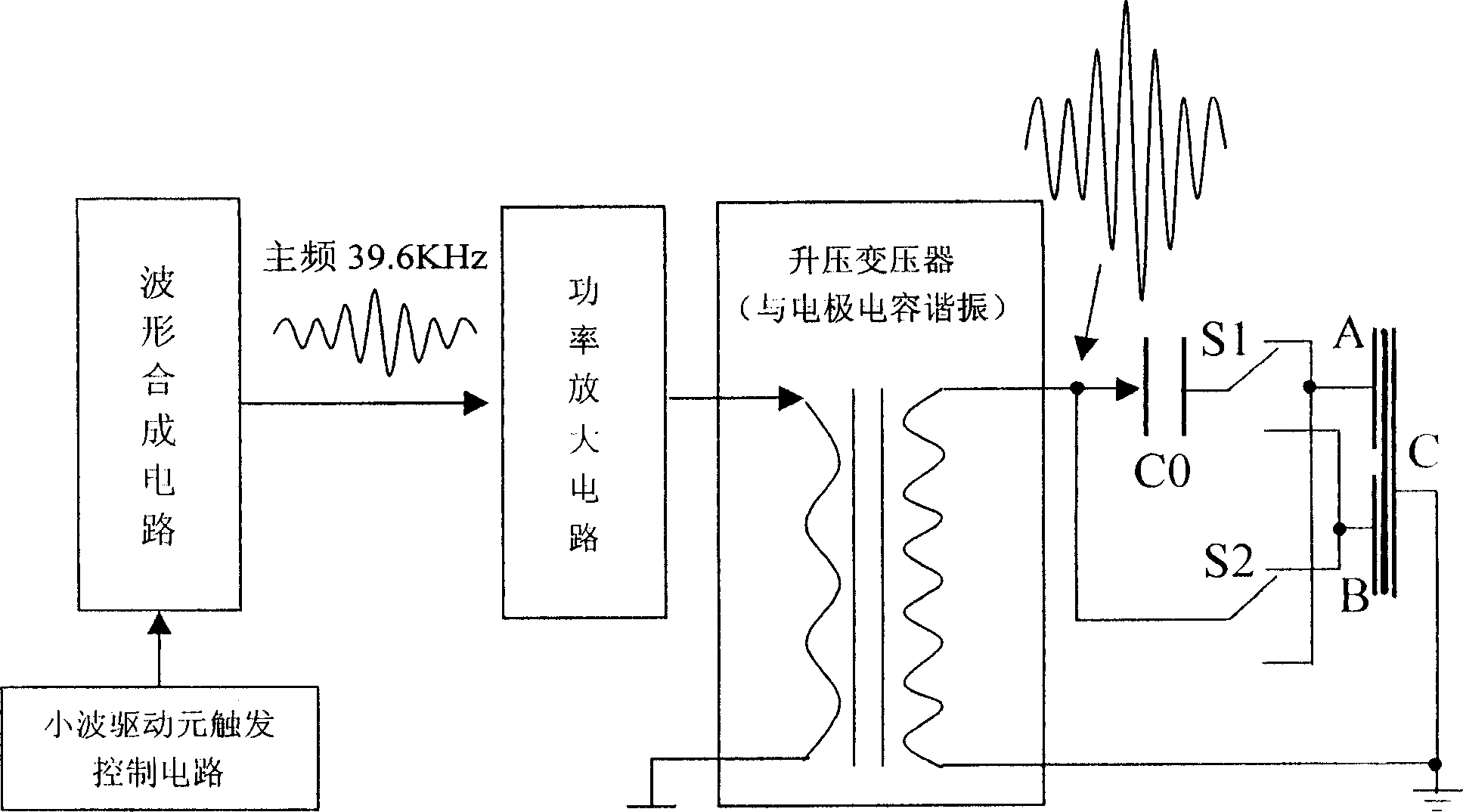

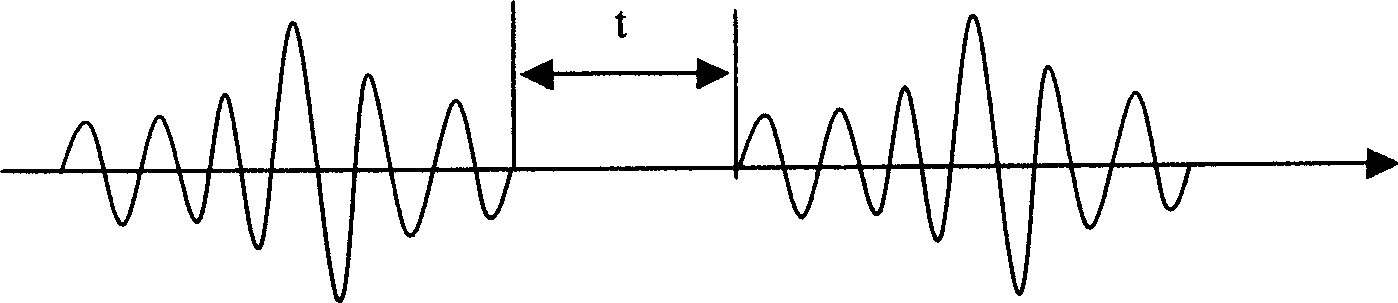

[0021] This embodiment adopts the wavelet differential control method, and the system configuration is as follows figure 2 As shown, the "waveform synthesis circuit" is used to generate the wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com