Decompressed microwave extraction device and method for extracting plant effective ingredient

A plant active ingredient and extraction device technology, which is applied in the field of plant active ingredient extraction devices to achieve the effects of reducing the vaporization temperature, increasing the speed, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

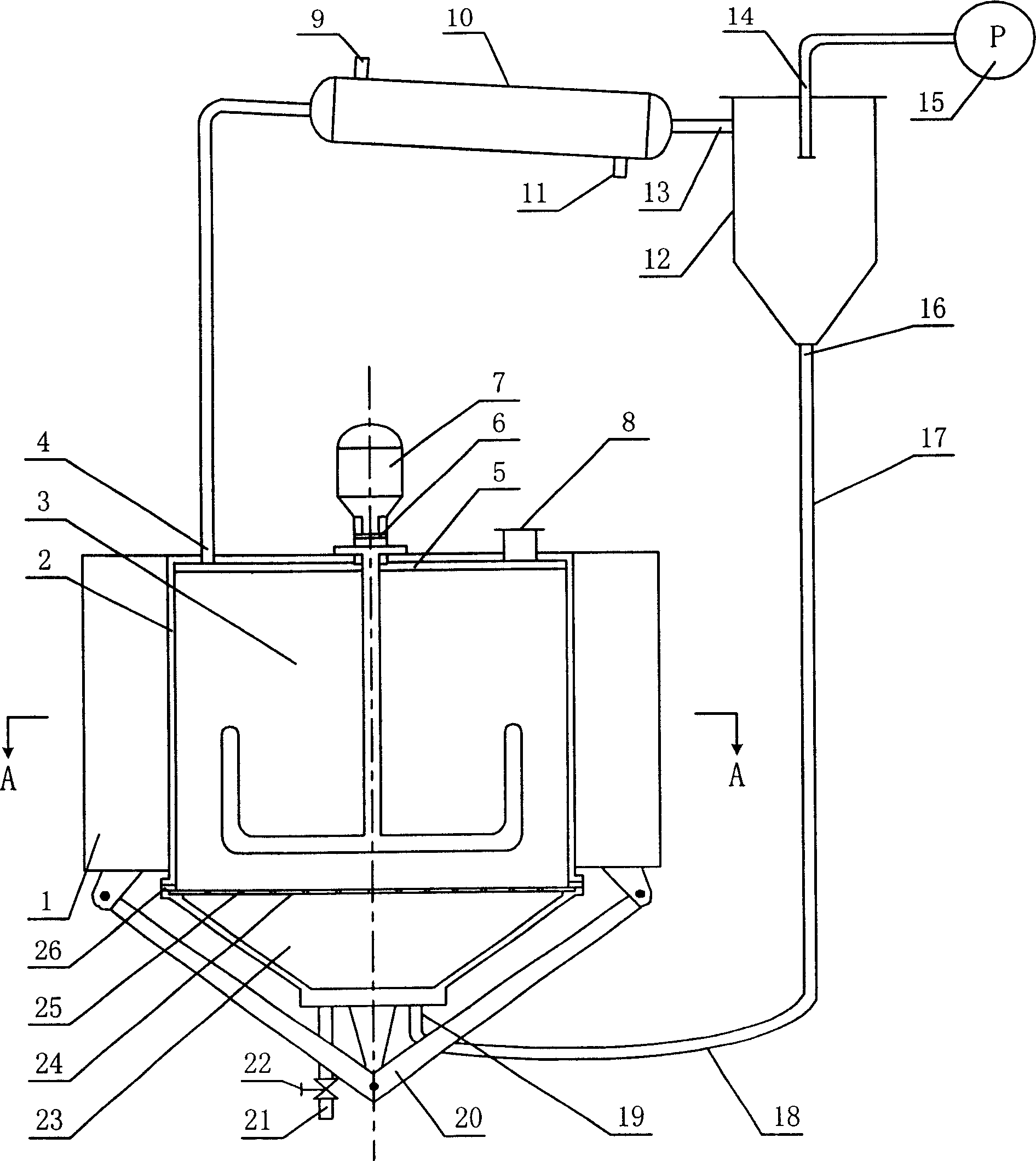

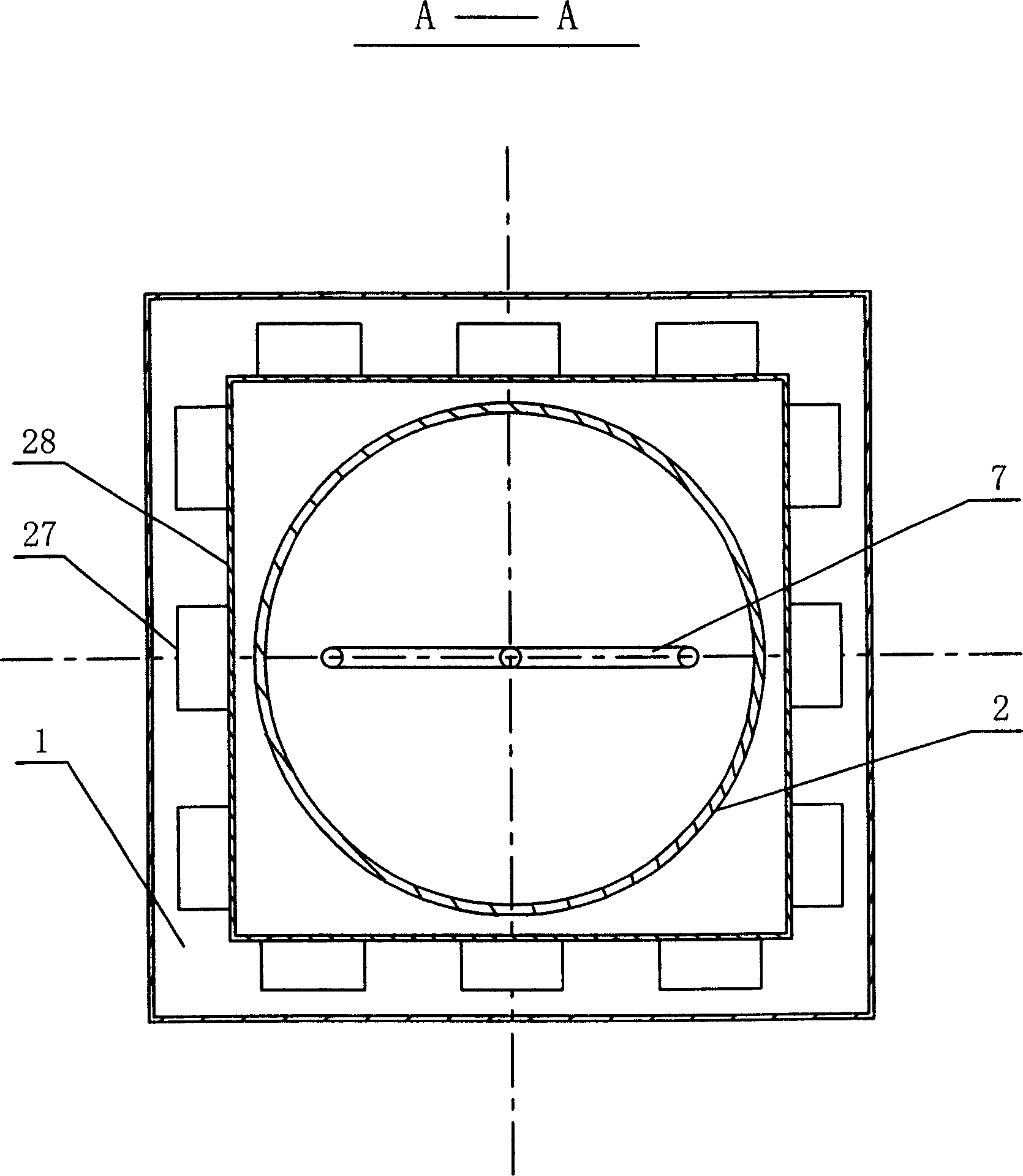

[0022] figure 1 Among them, the present invention is a microwave extraction system for decompression solvent circulation, including a microwave oven 1, an extraction tank 2, a condenser 10, a gas-liquid separator 12, and a decompression device 15; the microwave oven 1 is evenly arranged outside the metal protective layer 28 Generator 27, protection layer 28 is positioned at the periphery of extraction tank 2, as figure 2 As shown; the outer wall of the microwave oven 1 and the outer wall of the extraction tank 2 outside the microwave oven form a closed microwave cavity to prevent microwave leakage.

[0023] Inside the extraction tank 2 is an extraction chamber 3, on which there is a degausser 5 to prevent microwave leakage and metal ignition; the agitator 7 is installed in the extraction chamber 3 to ensure that the materials in the extraction chamber 3 are evenly mixed, and a seal is provided at the contact point device 6, and the upper part of the extraction chamber 3 also...

Embodiment 2

[0028] The extraction method of the present invention comprises: crushing the dried scutellaria baicalensis into 50-100 meshes and adding it to the extraction chamber of the extraction tank, then adding 600-1200% water by weight of the material in the extraction tank, and the volume of water and scutellaria baicalensis accounts for 2% of the total extraction tank volume. 50-65%, heating in a 2450MHz frequency microwave field with a vacuum degree of 300-500mmHg column conditions, carry out 8-16 minutes of decompression solvent circulation microwave extraction, close the microwave extraction device after the end, collect the extraction solvent and heat it on a water bath to 70-85°C, keep warm for 20-40 minutes to make the precipitation complete, let it stand for 10-14 hours, separate the precipitate, wash with distilled water 2-3 times, and dry to obtain the crude baicalin. Compared with the existing atmospheric pressure microwave extraction method, the extraction rate of baicali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com