Method for determining a maximum power point voltage of a fuel cell and use thereof

A maximum power point, fuel cell technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as power generation efficiency decline, fuel cell electrode degradation, and insufficient output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

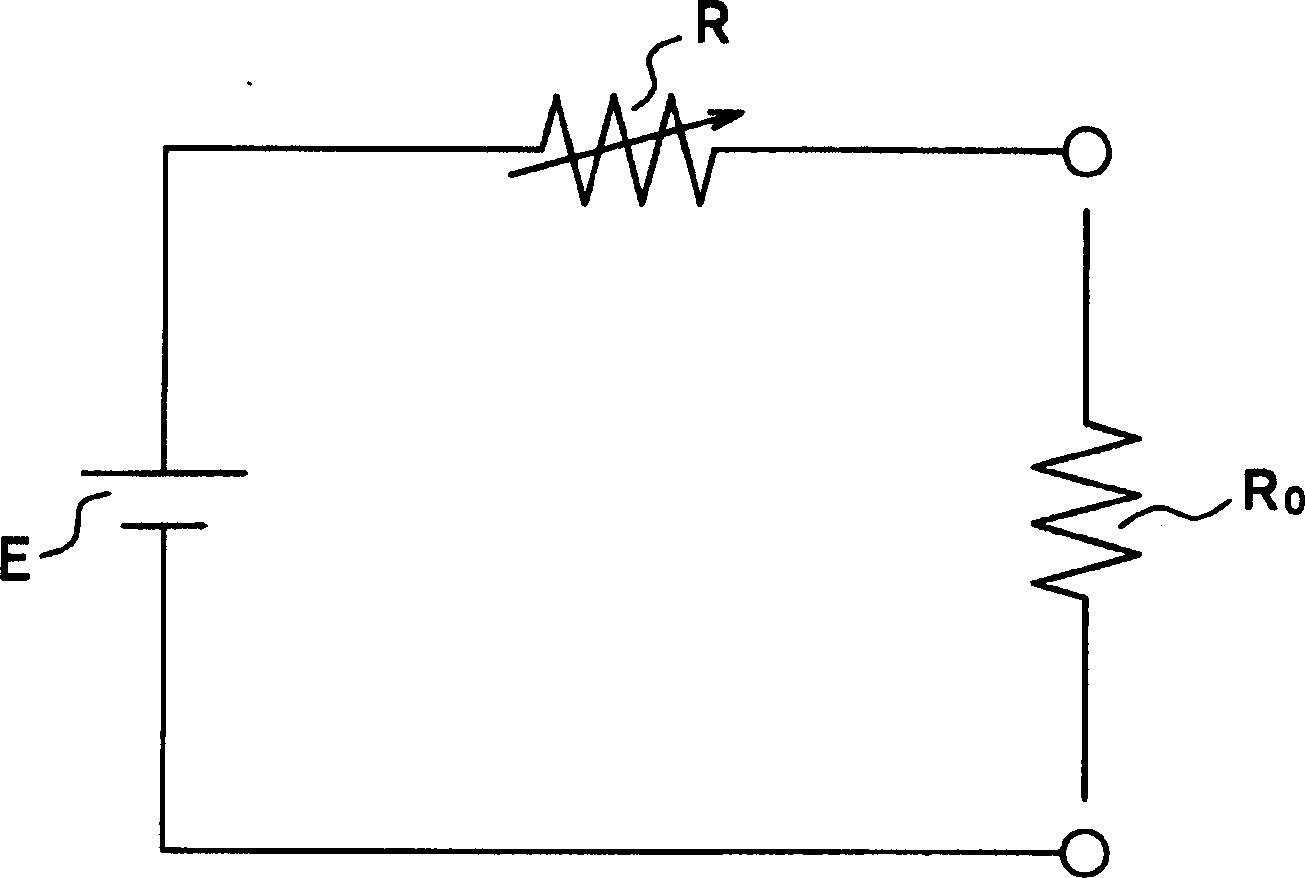

[0062] Figure 4 It is a configuration diagram showing a configuration example of the fuel cell control system according to Embodiment 1 of the present invention. This fuel cell control system is roughly divided into a fuel cell 1, an electric double-layer capacitor (EDLC) 2 as an electric storage unit, a circuit unit 3 composed of a step-up converter or a step-down converter, and a counter circuit unit 3 A control IC (power control device) 4 for switching control. This fuel cell control system is applied to portable electronic equipment, and the fuel cell 1 is a direct methanol fuel cell.

[0063] In this fuel cell control system, electric double layer capacitors 2 used as electric storage units each have a withstand voltage of 2.3V to 3.3V. Therefore, if Figure 4 As shown, when two cells are used in series, the withstand voltage is greater than or equal to 4.6V. This fuel cell control system can be applied to portable telephones, Electronic devices such as PDAs (Persona...

Embodiment approach 2

[0094] Figure 8 It is a configuration diagram of a fuel cell control system according to Embodiment 2 of the present invention. In this fuel cell control system using the control IC 4a, this control IC 4a, and Figure 6 Compared with the control IC 4 of the fuel cell control system of the first embodiment shown, the internal structure is different. Circuit section 3a and other structures, with Figure 6 The fuel cell control system shown is the same.

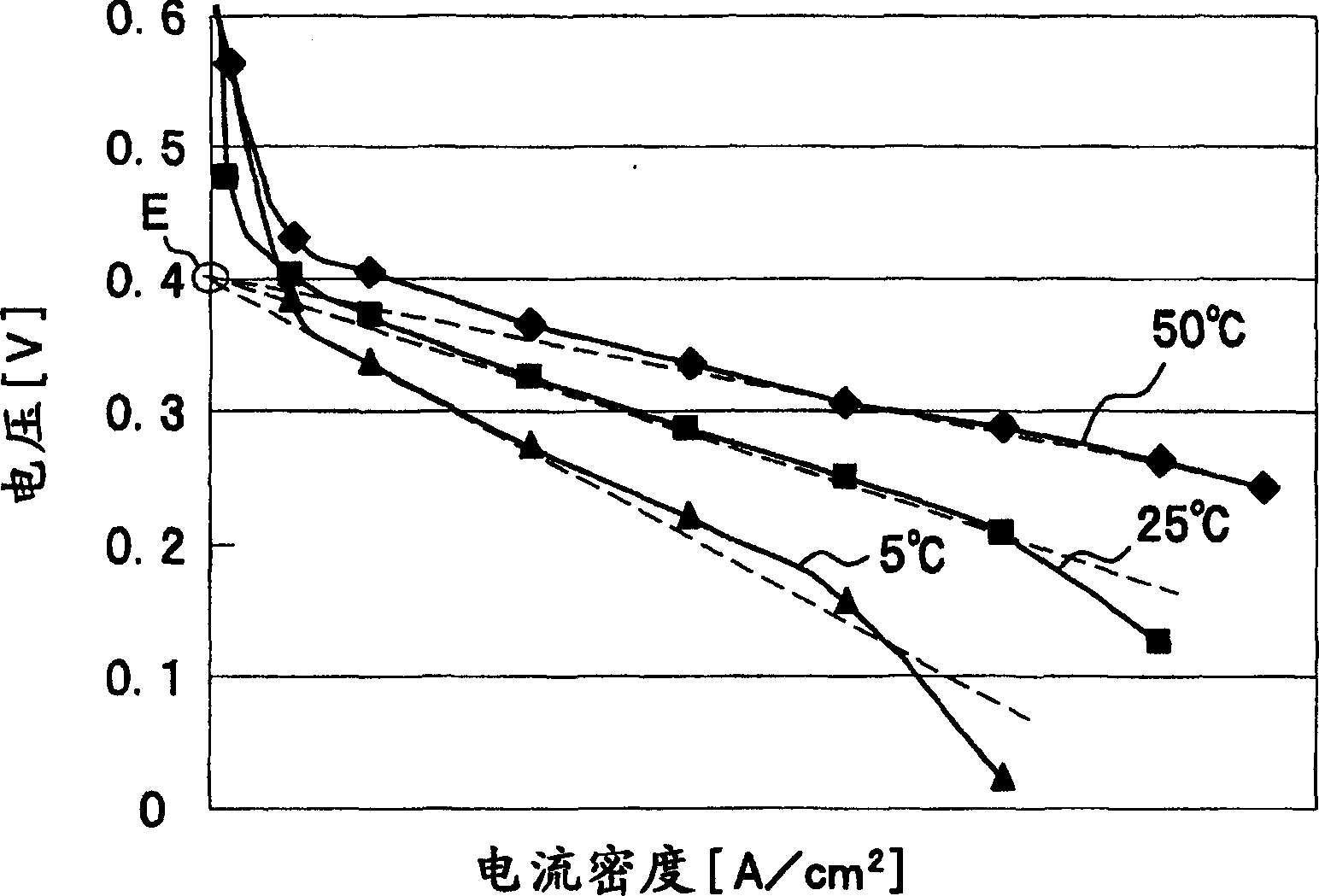

[0095] The control IC 4 a is composed of a control unit 11 a and a reference voltage setting unit 12 . The voltage is divided by the resistor R3 and the resistor R4, and the output voltage of the circuit part 3a input from the storage voltage terminal Fbout is compared with the second reference voltage Vref2 by the differential amplifier S3, and the differential voltage (hereinafter referred to as the output voltage difference) is output to one terminal of the reference voltage setting section 12. The temperature voltage o...

Embodiment approach 3

[0105] Figure 10 It is a configuration diagram of a fuel cell control system according to Embodiment 3 of the present invention. Figure 10 Compared with the fuel cell control systems of Embodiments 1 and 2, the fuel cell control system according to Embodiment 3 shown is not a synchronous rectification type, but a Schottky barrier diode 15 is used instead. The structure of the step-up chopper method. That is, in Figure 10 of circuit section 3b, the Figure 6 The P-channel power MOSFET 14 of the circuit portion 3 a is replaced with a Schottky barrier diode 15 . By adopting this structure, with Figure 6 Embodiment 1 of and Figure 8 Compared with the structure of Embodiment 2, it is effective for the case where the voltage at the output terminal is higher.

[0106] next to Figure 10 The control IC 4b of Embodiment 3 shown will be described in detail. The control IC 4b of Embodiment 3, and Figure 4 and Figure 6 The control IC 4 of Embodiment 1 shown and Figure 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com