Automatic computer jacquard

A technology of jacquard flat knitting machines and computers, which is applied to jacquard machines, electrical components, electric heating devices, etc., and can solve problems such as difficulty in correct position control, increased production costs, and increased system weight, achieving excellent position control, easy maintenance, and reduced noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

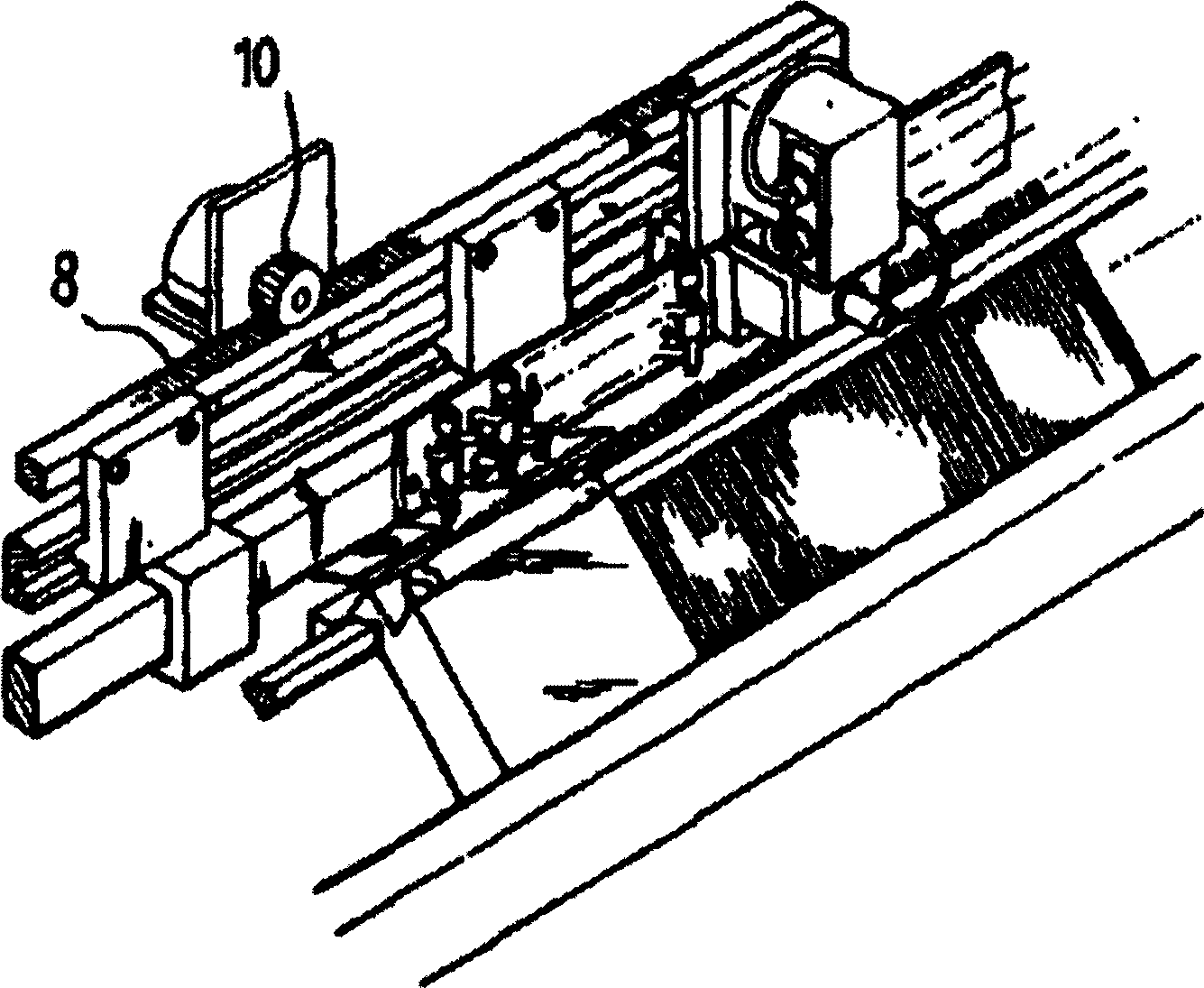

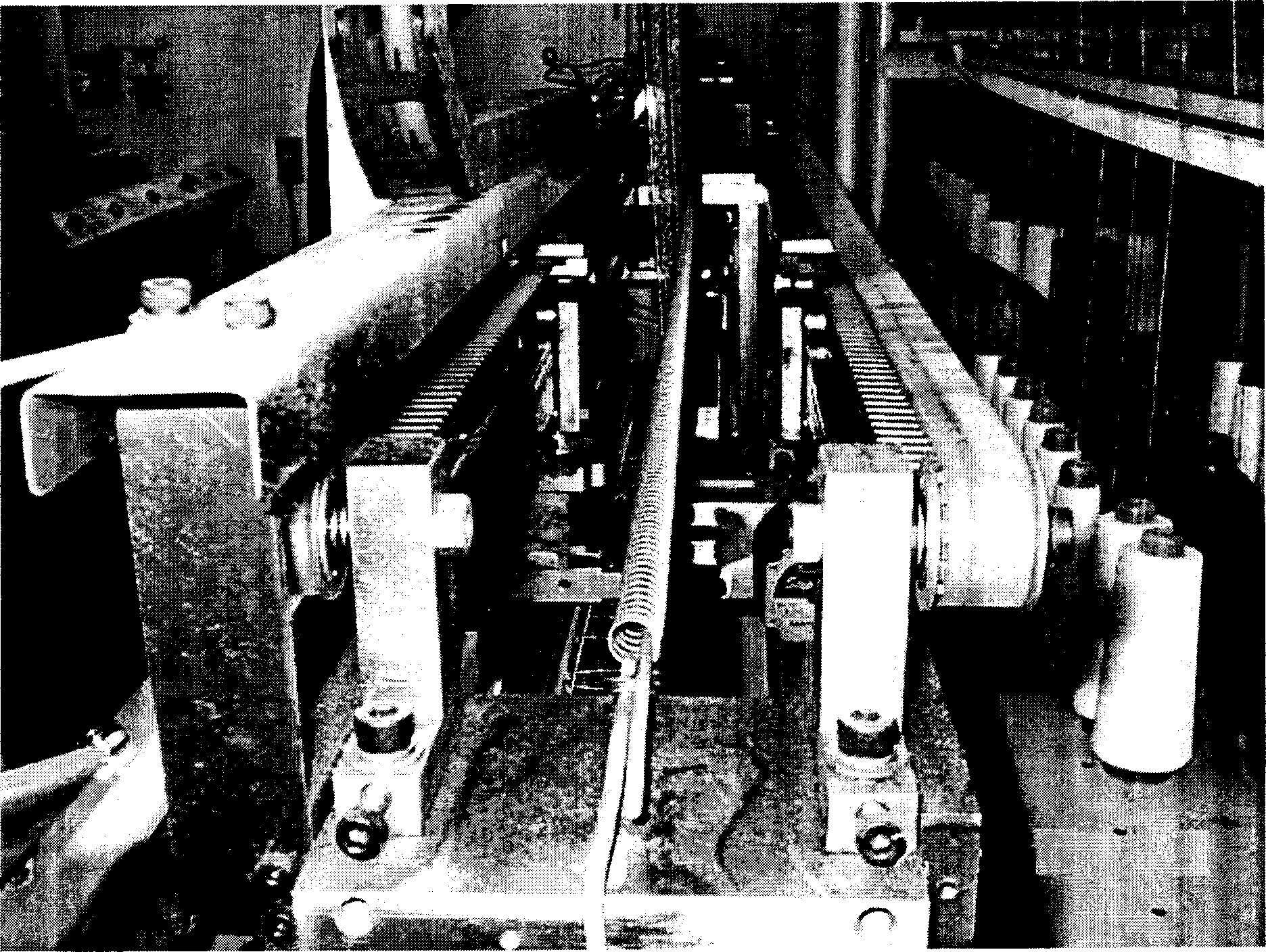

[0018] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0019] The present invention relates to an automatic computer jacquard flat knitting machine, which includes a yarn feeder conveying device 11 and a yarn feeder conveying device moving motor 9 for moving the yarn feeder conveying device 11, which includes:

[0020] Two synchronous pulleys 13, 13' respectively connected to the upper end and lower end of the rotating shaft 12 of the moving motor 9 of the yarn feeder conveying device;

[0021] A pair of timing belts 14, 14' with one end connected to the timing pulleys 13, 13' in the moving direction of the yarn feeder conveying device 11;

[0022] A first idler pulley 15 connected by the other end of the first synchronous belt 14 in the pair of synchronous belts 14, 14';

[0023] Connected by the other end of the second synchronous belt 14' in the pair of synchronous belts 14, 14', the second idler pulley 15' whos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com