Plant cultivating base body and method of manufacturing the same

A manufacturing method and substrate technology, applied in botany equipment and methods, cultivation, culture medium, etc., can solve the problems of filling materials falling, failure to maintain shape retention, and fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Regarding the plant cultivation base according to the present invention and the method for producing the plant cultivation base, the embodiments thereof will be described with reference to the drawings and experimental results.

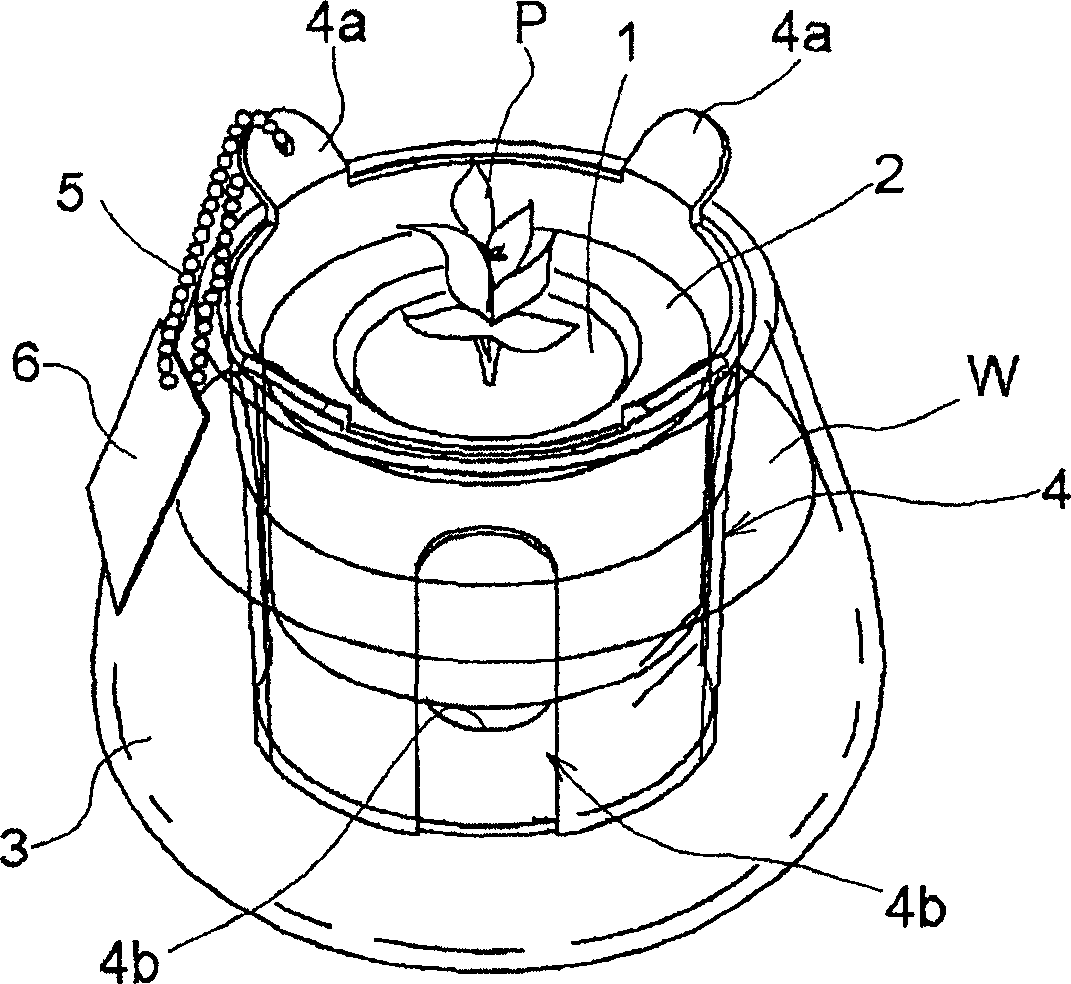

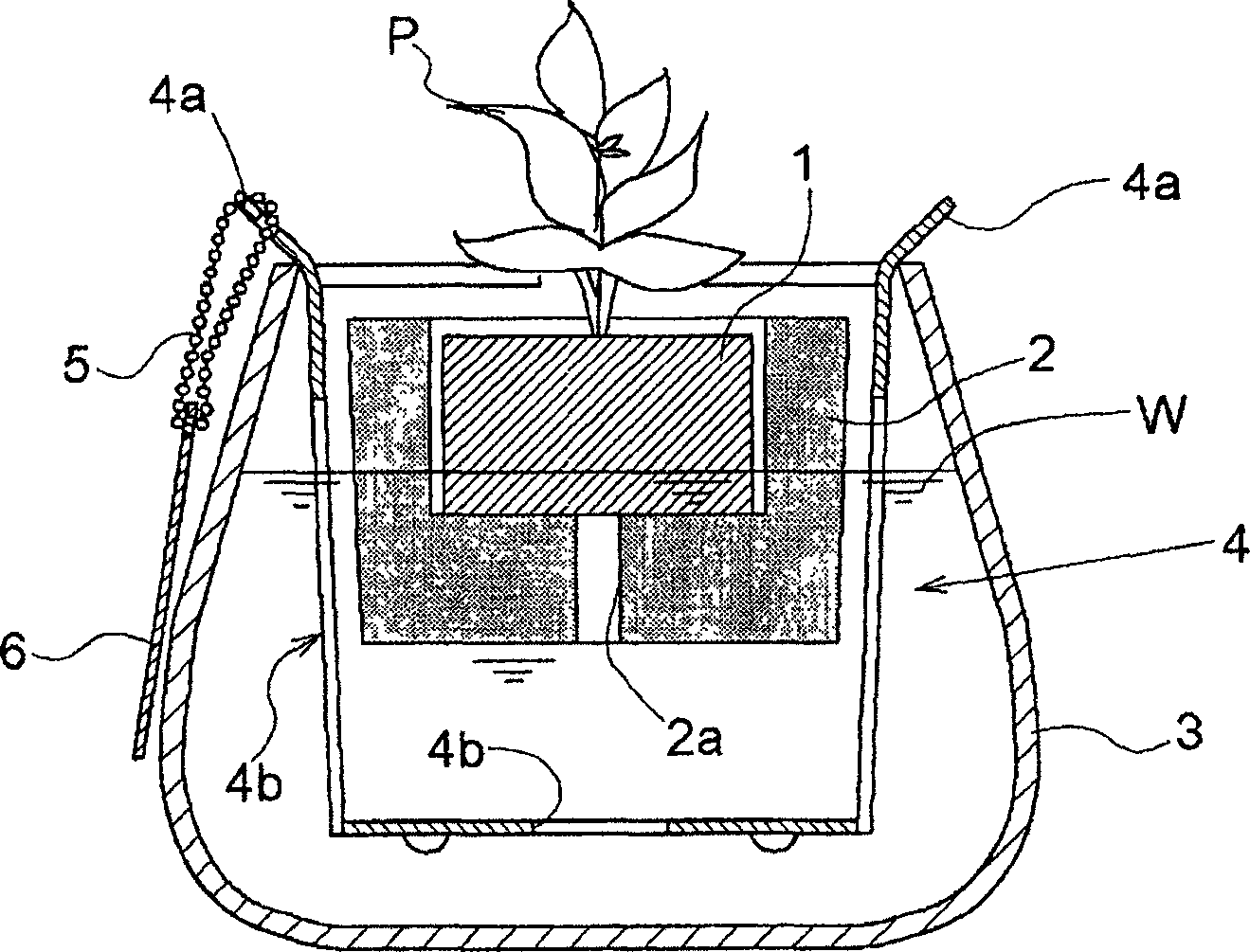

[0047] The plant cultivation substrate can be used for, for example, a planting device for planting while floating a planting container on water. The floating planting device, such as figure 1 with figure 2 As shown, a planting container 2 for storing a plant cultivation base 1, a water storage container 3 for storing planting water W, a planting tool 4 for maintaining the floating posture of the planting container 2 and the like are provided to cultivate the planted in the plant cultivation base 1. Plant P.

[0048] The planting container 2 floats near the water surface of the stored water W, is formed into a bottomed cylindrical shape with a hollow resin having a specific gravity smaller than water, and has a water immersion hole 2a penetrating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com