Three-point type position control method based on slide distance

A technology of sliding distance and control method, applied in the field of position control of mobile devices, can solve the problems of control uncertainty, asynchronous control signal and actual action, output signal hysteresis, etc., to avoid the effect of swing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

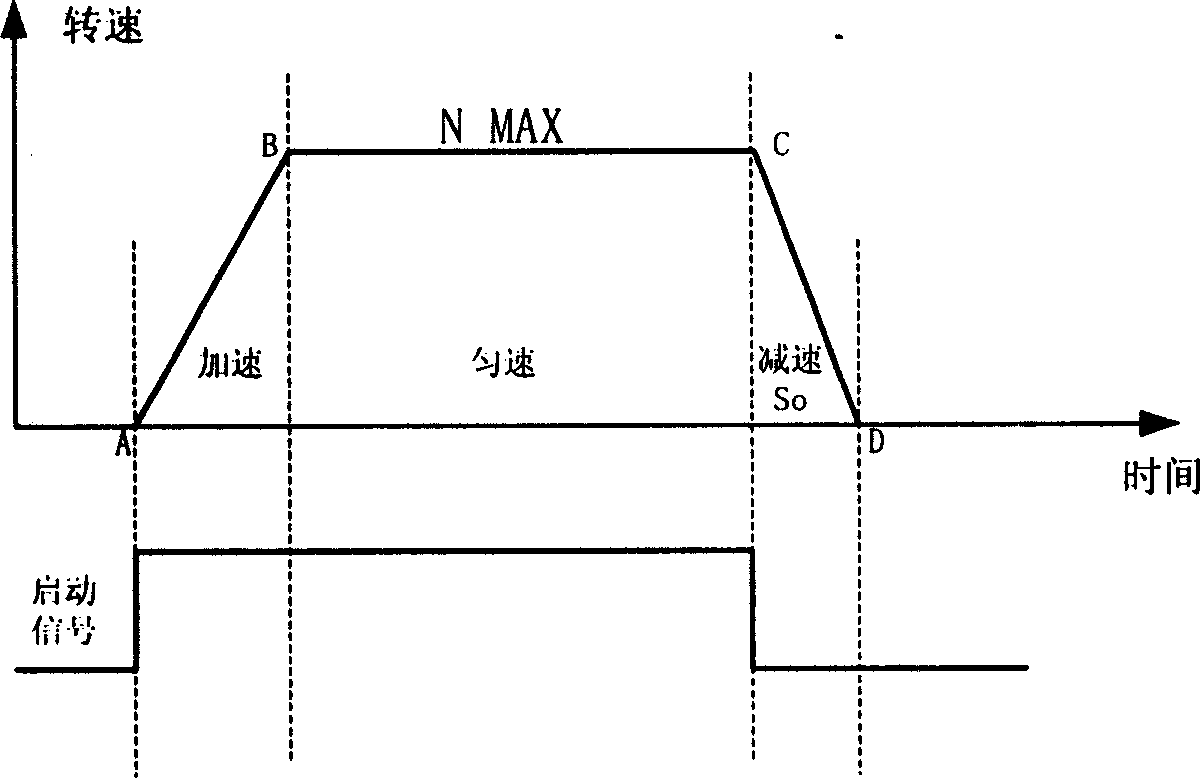

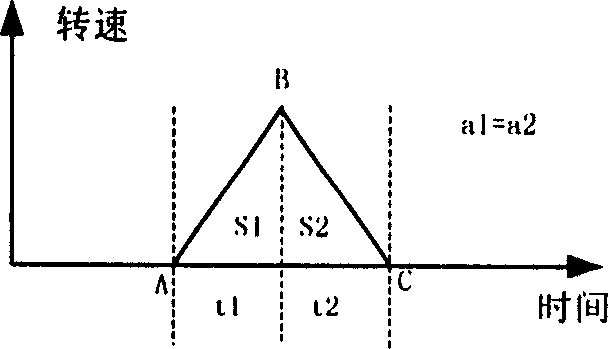

[0052] Such as Figure 6 Shown: the position control method based on the sliding distance of the invention of the present invention comprises the following steps:

[0053] 1. New setting value Wo issued: This is a pulse trigger signal, indicating that the process machine has issued a width value different from the previous one, and the device needs to be re-adjusted.

[0054] 2. Situation 1: X

[0055] 3. Situation 2: X>Wo: If the current position is smaller than the target position value, it indicates that it needs to move in the direction of width reduction, and then issue t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com