Rotation durability testing device for whip-shaped lock

A technology of durability test and whip lock, which is applied in the direction of measuring device, mechanical component test, machine/structural component test, etc. It can solve problems such as small angle range of measurement, test data integrity discount, whip lock swing, etc. , to achieve the effects of improving accuracy and integrity, easy mass production, and convenient disassembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Depend on figure 1 Shown is a schematic structural view of the whip lock rotation durability test device of the present invention, including a working platform 1, a welding corner seat 2 fixed on the working platform 1, and a locking buckle for fixing the whip lock buckle is fixed on the welding corner seat 2 The fixture assembly 3007 is fixed on the swinging platform 11 on the working platform 1, and the rotating fixture assembly 8010 is fixed on the swinging platform 11.

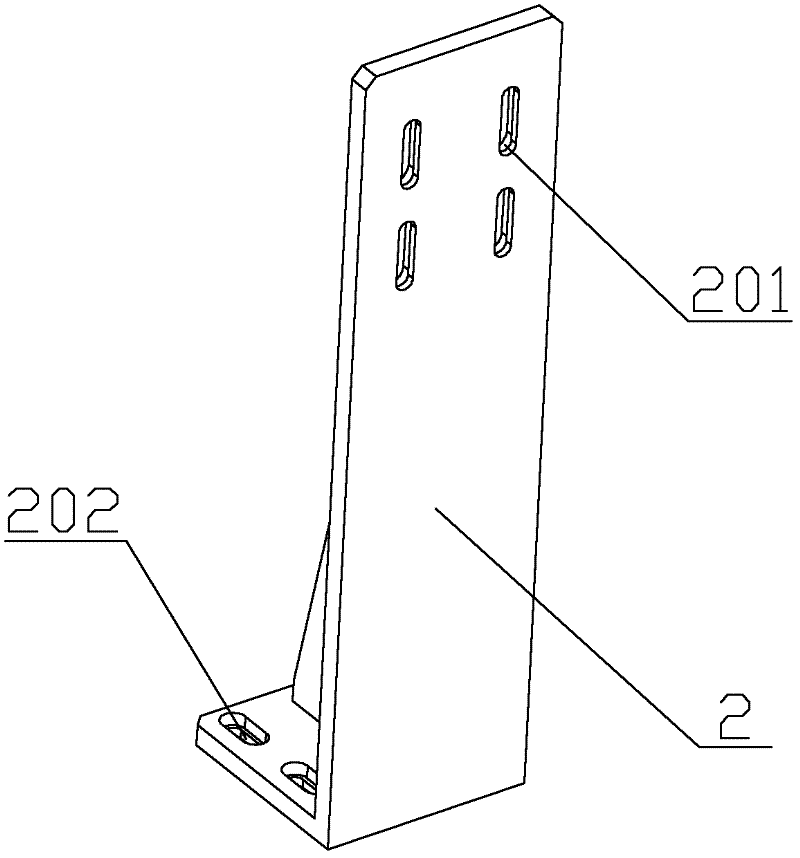

[0035] Depend on Figure 2-9 From the combination of the shown structures, it can be seen that the welding corner seat 2 is provided with an adjustable fixing screw hole 202 for fixing the working platform 1 ; and an adjustable fixing screw hole 201 for fixing the locking fixture 3 .

[0036] The locking fixture assembly 3007 includes the locking fixture 3, the fixture moving blocks 401 and 402, the fixture bottom plate 5 and the main fixture cover plate 6; the locking fixture 3 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com