Easy-to-detach type fan electromotor installation structure for indoor unit of air conditioner

A technology for air-conditioning indoor units and indoor unit fans, which is applied in the field of easy-to-detach fan motor installation structures for air-conditioning indoor units, which can solve the problems of fan and motor noise, structural vibration noise, etc., and achieve the effect of avoiding vibration noise and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

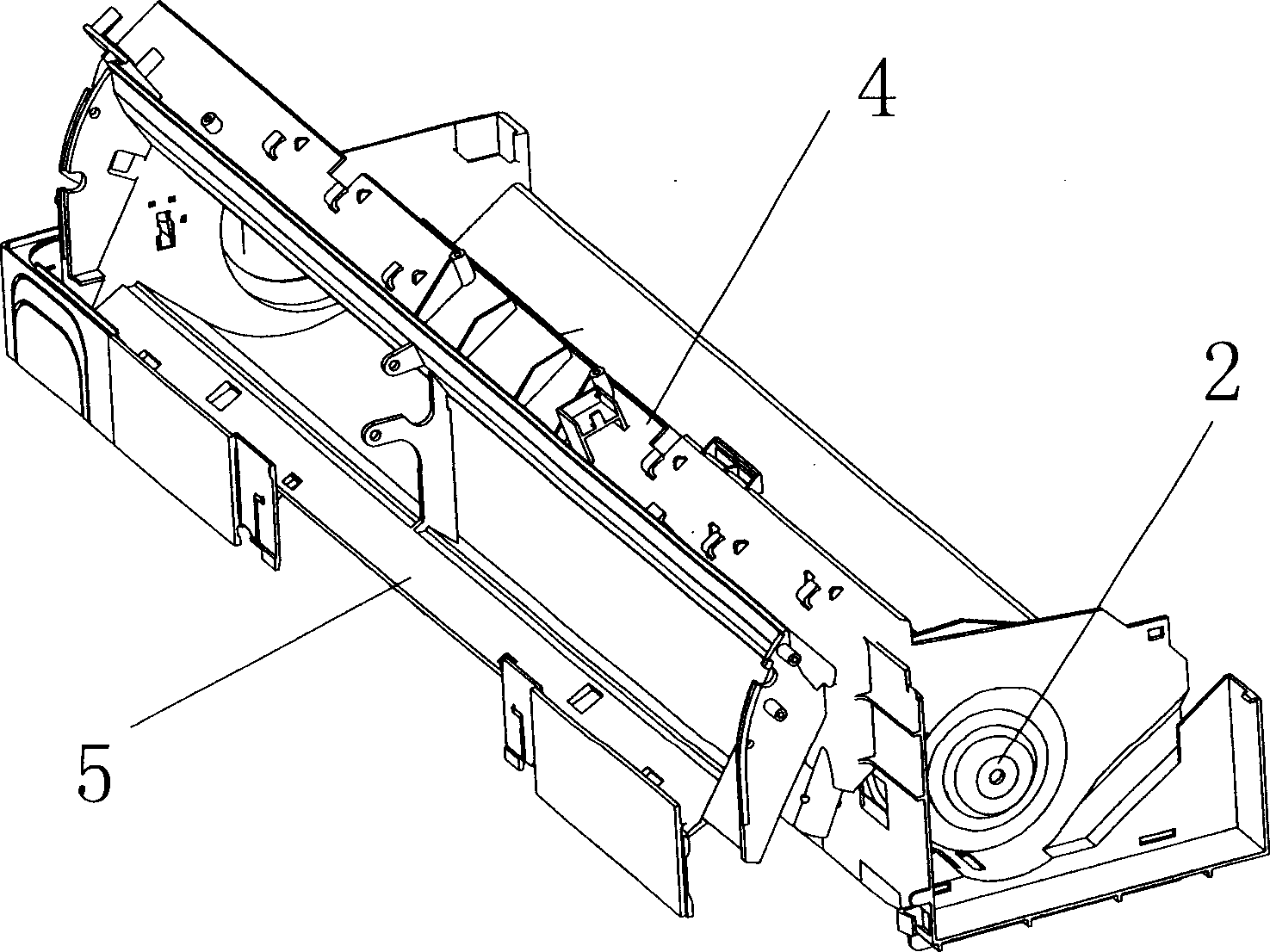

[0036] As a simple way, the simplest implementation in this embodiment, see image 3 , but with image 3 The slight difference is that the motor cover is not used in this embodiment.

[0037] One end side of the base 5 is provided with a motor chamber 1 for accommodating the motor 2 standing upright on one side. Because there is no fixing effect of the motor cover plate, a matching fixing device matched with the motor chamber fixing device is set on the shell of the motor. For example, as shown in the figure, two screw holes are provided on the periphery of the motor chamber 1, then two screw holes are also provided at the corresponding positions of the motor casing, and the motor is fixed in the motor chamber by screws. Although this method has a simpler structure, it has special requirements on the motor casing, which brings some inconvenience, so it is not the best method.

Embodiment 2

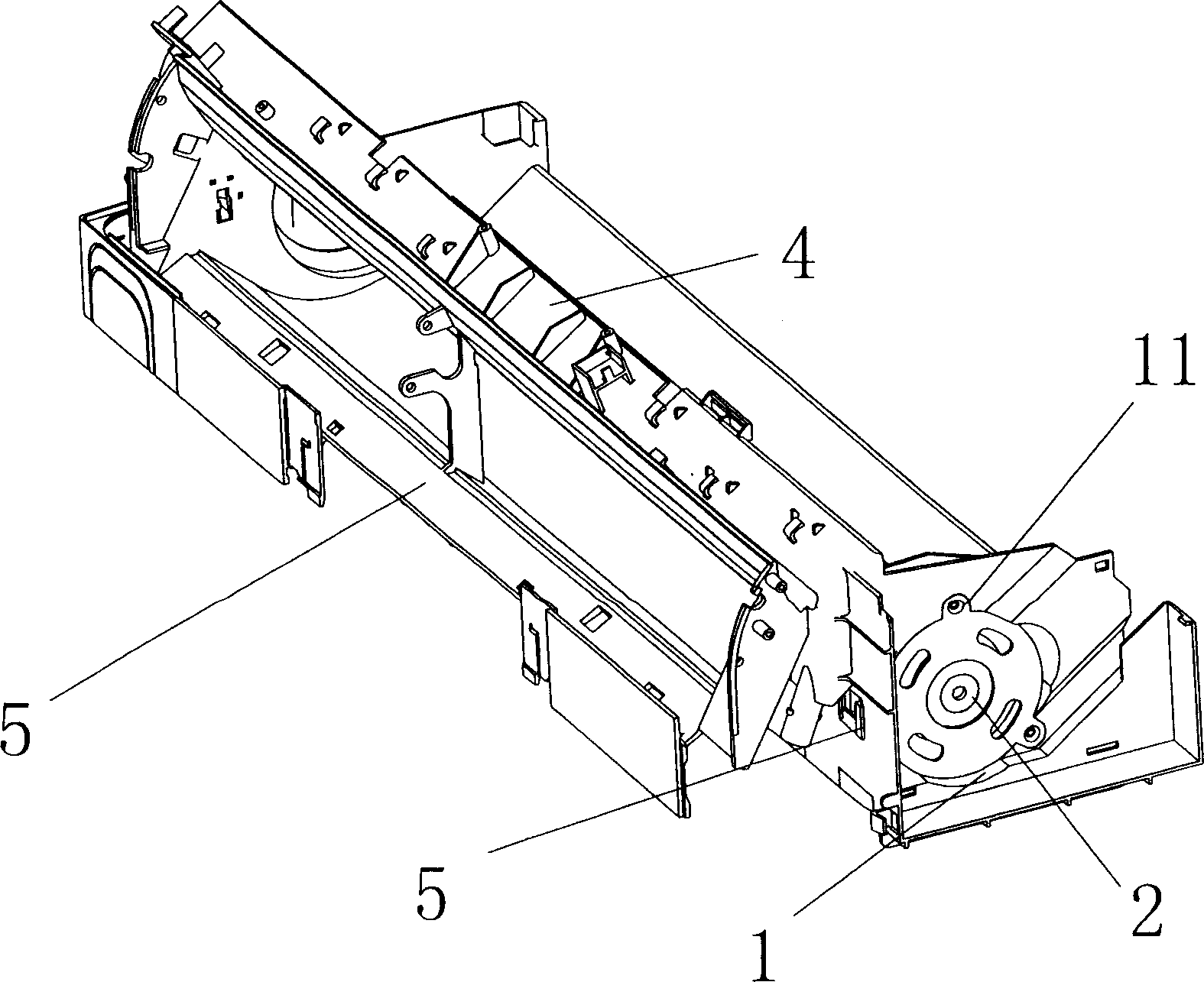

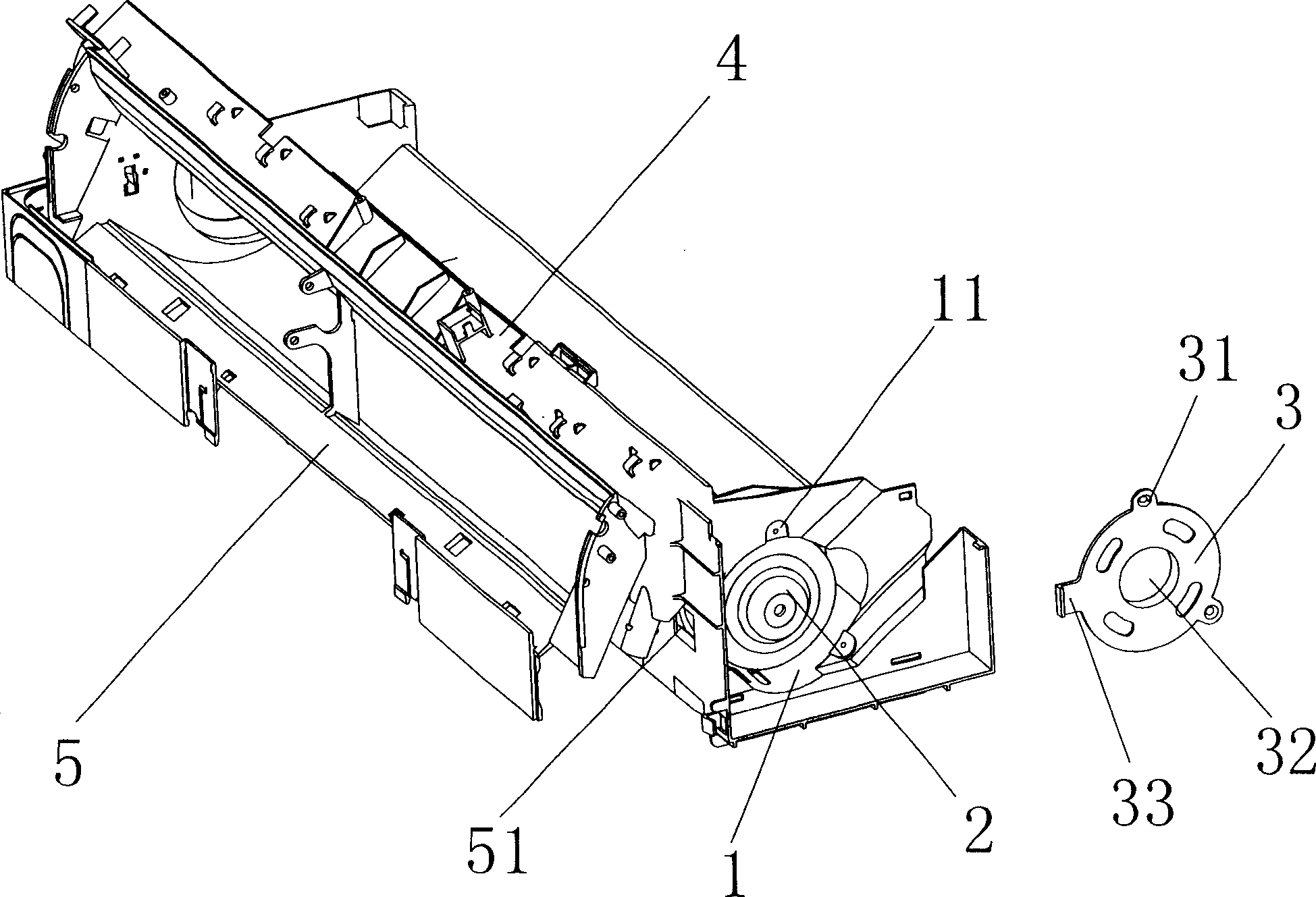

[0039] In this way, use the motor cover, such as Figure 2 to Figure 4 As shown, the fixing device 11 on the periphery of the motor cavity is two first screw holes, and the matching fixing device 31 matching the fixing device is two second screw holes, put the motor into the motor cavity, and insert the motor shaft into the fan shaft hole , Then, the motor cover plate 3 covers the opening of the cavity, and the first screw hole and the second screw hole are screwed and fixed into one body by screws. When covering the motor cover plate 3, a positioning device 33 that is convenient for the motor cover plate to align with the motor cavity is provided on the edge of the motor cover plate 3, and the positioning device 33 is a small rectangular sheet integrated with the motor cover plate shaped claw, or a small semicircular convex button integrated with the motor cover or in other ways, at the same time, a matching positioning device matching the size and shape of the positioning de...

Embodiment 3

[0042] The structure is basically the same as that of Embodiment 2 (the structure is omitted in the drawings), except that the fixing device 11 on the periphery of the motor cavity has two buckles or slots, and the matching fixing device 31 matching the fixing device has two slots or buckle, put the motor into the motor chamber, insert the motor shaft into the fan shaft hole, then cover the opening of the cavity with the motor cover 3, and fasten the motor cover through the buckle / slot and the slot / slot It is snapped and fixed into one body with the motor cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com