Domestic full-automatic dish-washing machine and its cleaning method

A fully automatic, dishwasher technology, used in household cleaning devices, dishwashers/washing machines for tableware, household appliances, etc. Cleaning and other problems, to achieve the effect of fast cleaning, good cleaning effect, and ensuring good health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

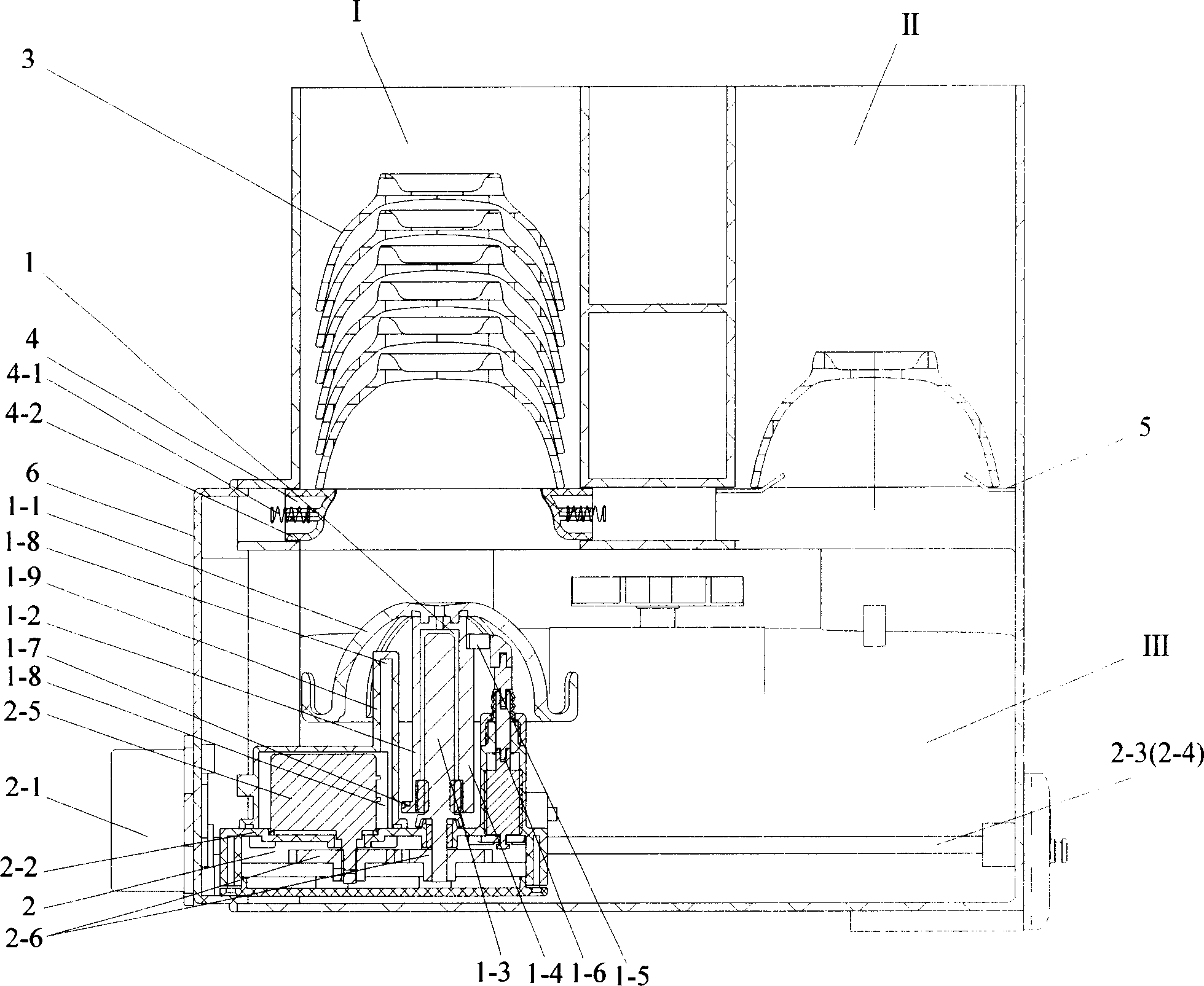

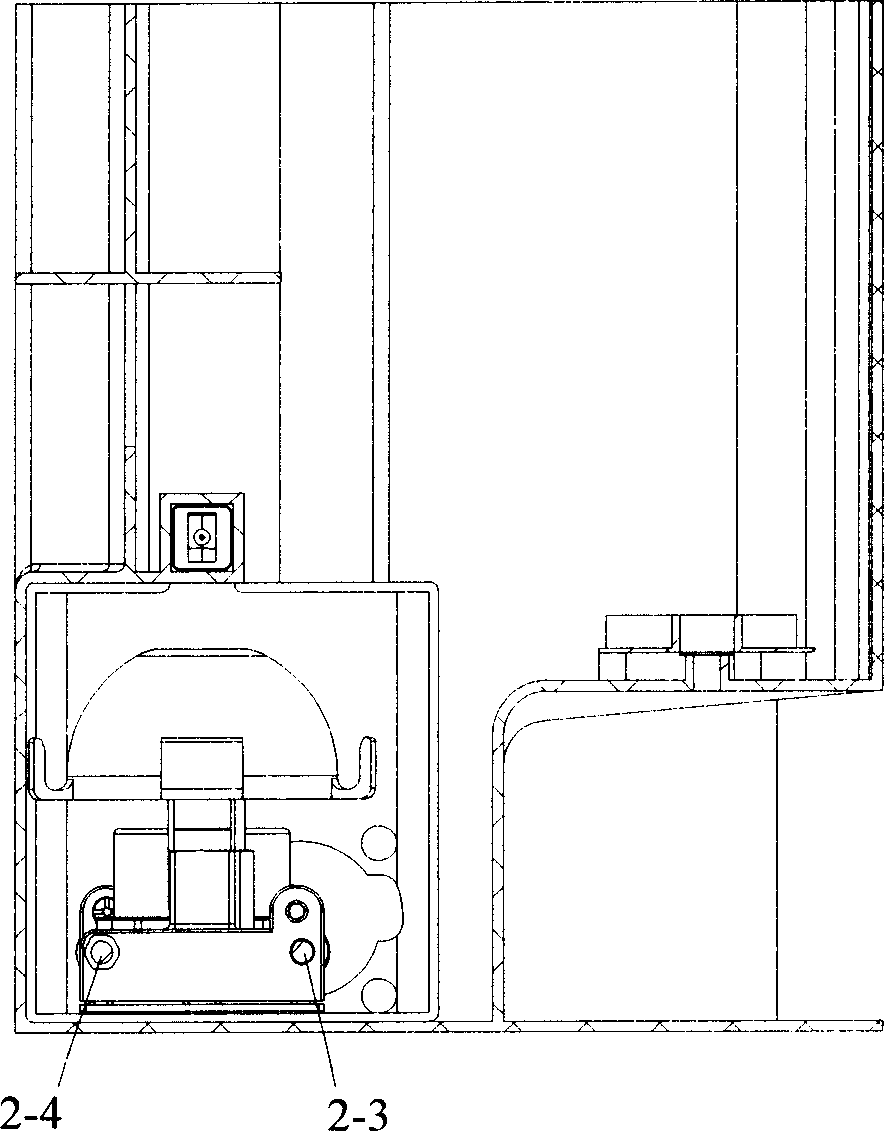

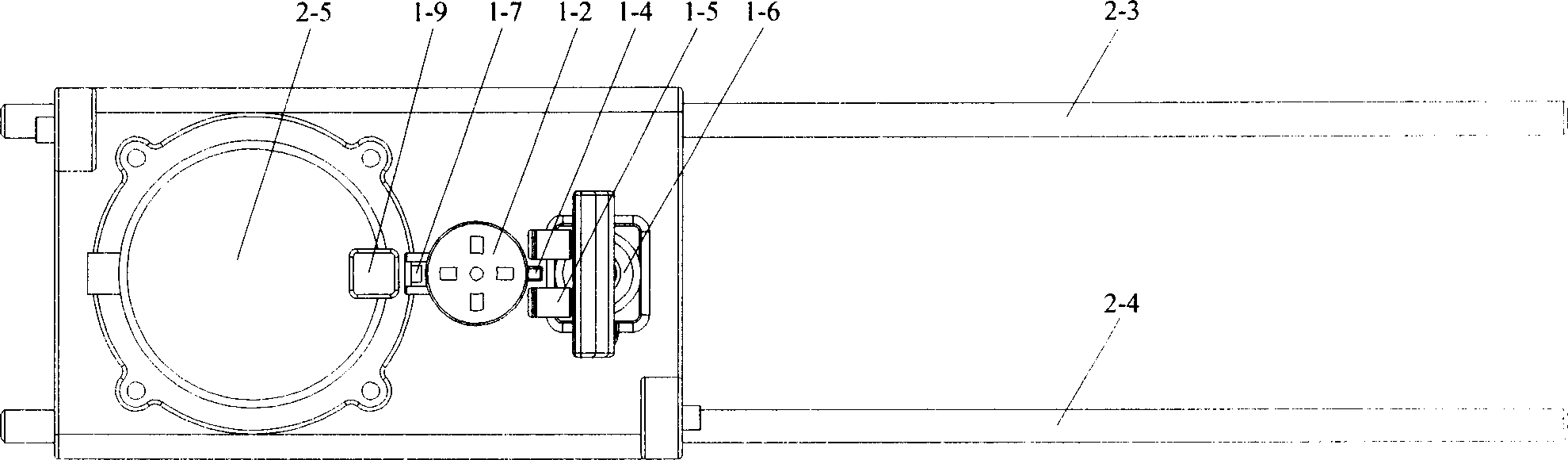

[0026] Figure 1 ~ Figure 3 shows the concrete structure of the present invention, by figure 1 with figure 2 It can be seen that the fully automatic dishwasher includes an unwashed area I, a dishwashing area II, and a drying area III. II is connected, and a cleaning head 1 that can be lifted vertically is arranged in the dishwashing area II, and the cleaning head 1 is connected with a horizontal transmission mechanism 2 . The cross-sectional shape of the unwashed area I is circular, and the diameter of the circle is greater than the diameter of the bowl 3. The bowls 3 can be stacked upside down in the unwashed area I; Elastic clamping block 4, described elastic clamping block 4 is made of spring 4-1 abutting clamping block 4-2, the bowl 3 in the unwashed area 1 abuts on the upper end of described elastic clamping block 4, and described elastic clamping block The lower end of 4 is processed with a chamfer close to the radian of the bowl 3 contour. The cross-sectional shape...

Embodiment 2

[0029] This embodiment is the same as Embodiment 1 except for the following technical features: the outer surface of the internally threaded sleeve is provided with a positioning pin, and a positioning groove of a certain length is arranged opposite to the positioning pin, and the positioning groove is fixed on the sliding block , the positioning pin is detachably matched with the positioning groove; when the internal thread sleeve rises, the positioning pin can extend into the positioning groove, and limit its circumferential rotation while the internal thread sleeve rises; when the internal thread When the sleeve falls to the lowest point, the positioning pin is disengaged from the positioning groove, and the internally threaded sleeve can rotate freely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com