Seasoning and its production method

A manufacturing method and seasoning technology, which are applied in the fields of livestock and meat seasonings, vegetable seasonings, and fish and shellfish seasonings, can solve the problems of no prevention of flavor deterioration, no deterioration prevention, etc., and achieve the prevention of flavor deterioration and the improvement of free radical capturing ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] Regarding flavor changes, organoleptic evaluation was performed by 16 well-trained judges.

[0070] Measure the absorbance at a wavelength of 514 nm for free radicals of 1,1-phenylbenzene 1-2-trinitrophenyl 1 (1,1-Diphenyl-2-picrylhydrazyl, hereinafter denoted as DPPH) that generate relatively stable free radicals (hereinafter expressed as OD514), the amount of substance required to reduce the free radical capture ability (hereinafter expressed as RC%) and DPPH radical 30 μm by 50% (hereinafter expressed as RD50 value) was calculated by the following formula, and the effect on the prevention of flavor deterioration Supplementary evaluation of the doubling effect and persistence.

[0071] Calculation formula RC%

[0072] RC%=((Blank OD514—Sample OD514) / Blank OD514)×100

[0073] Calculation formula RD50

[0074] RD50=(50-b) / ΔT

[0075] ΔT=(Sample RC%—10 times diluted RC%) / Sample amount of hijiki—10 times diluted amount of hijiki)

[0076] b=Sample RC%—ΔT×Sargassum am...

Embodiment 1

[0080] Put 15 kg of dried bonito flakes coarsely crushed into φ5mm (Marmo Co., Ltd.) and 1 kg of “Hijiki No.1” (Sanchu Co., Ltd.) into 500 kg of water, heat and extract at 90°C for 20 minutes, and use centrifugation The liquid after solid-liquid separation by the separator is used as bonito juice, and the solid content measured by the sugar meter is adjusted to 1.5.

[0081] The solid content of hijiki in the flavor raw material is 6.7 parts by weight.

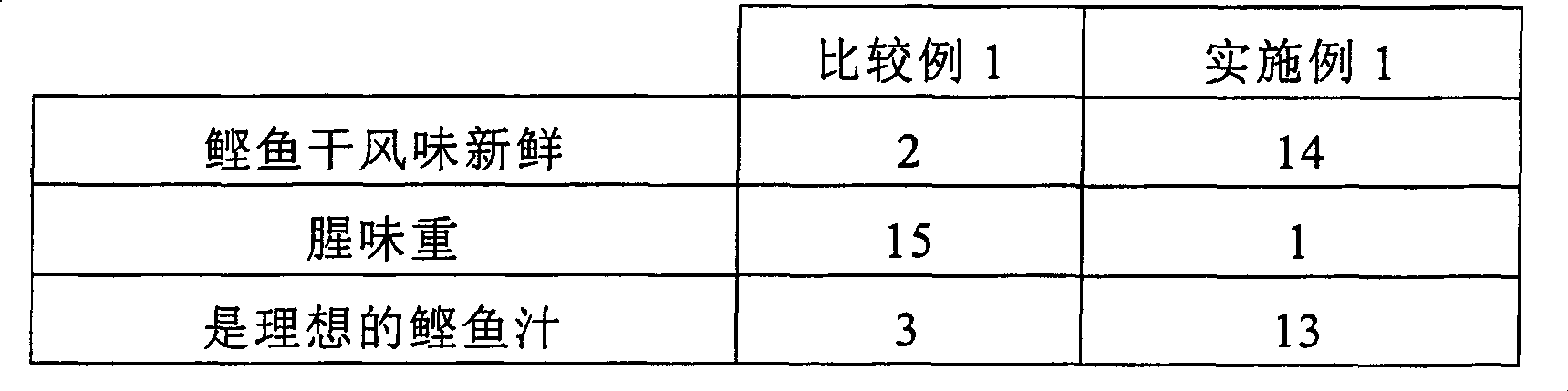

[0082] The sensory evaluation of Comparative Example 1 and Example 1 was performed at a temperature of 60°C. The results are shown in the table below. The values in the table represent the number of selected judges.

[0083] Table 1

[0084]

Embodiment 2

[0088] Example 1 was concentrated using a vacuum concentrator, so that the solid content measured by the sugar meter reached 15.

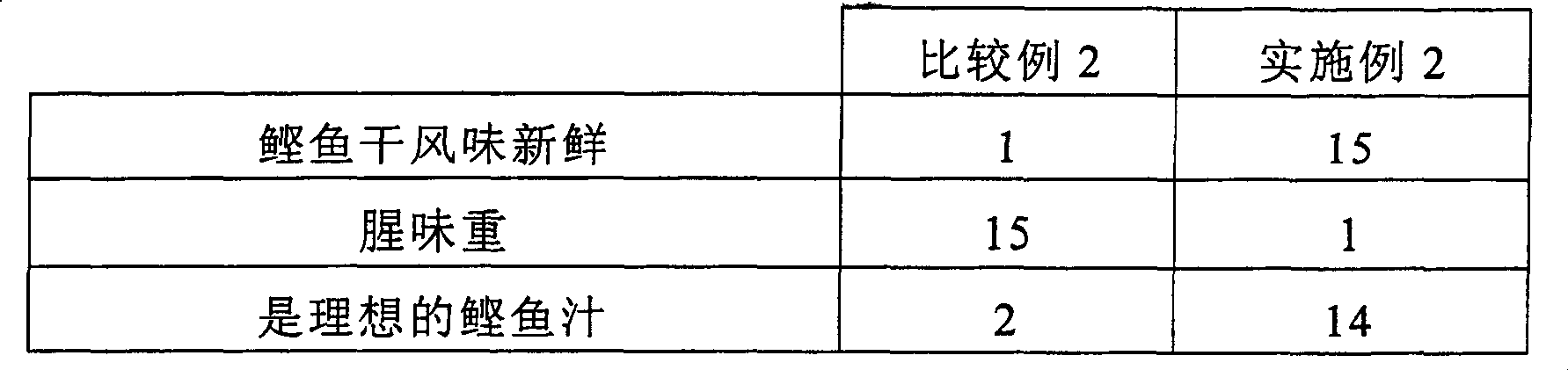

[0089] Comparative example 2 and Example 2 were diluted 10 times, and the sensory evaluation was performed at 60 degreeC. The results are shown in the table below. The values in the table represent the number of selected judges.

[0090] Table 2

[0091]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com