Method for improving absorption capacity of pork neck meat juice through multiple microbial fermentation

A technology of microbial fermentation and absorptivity, applied in food science, ultra-high pressure food processing, bacteria used in food preparation, etc., can solve problems such as affecting calcium and phosphorus balance, deterioration of color and flavor of meat products, etc., and improve water retention rate , Improve the absorption capacity of gravy and the effect of good water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

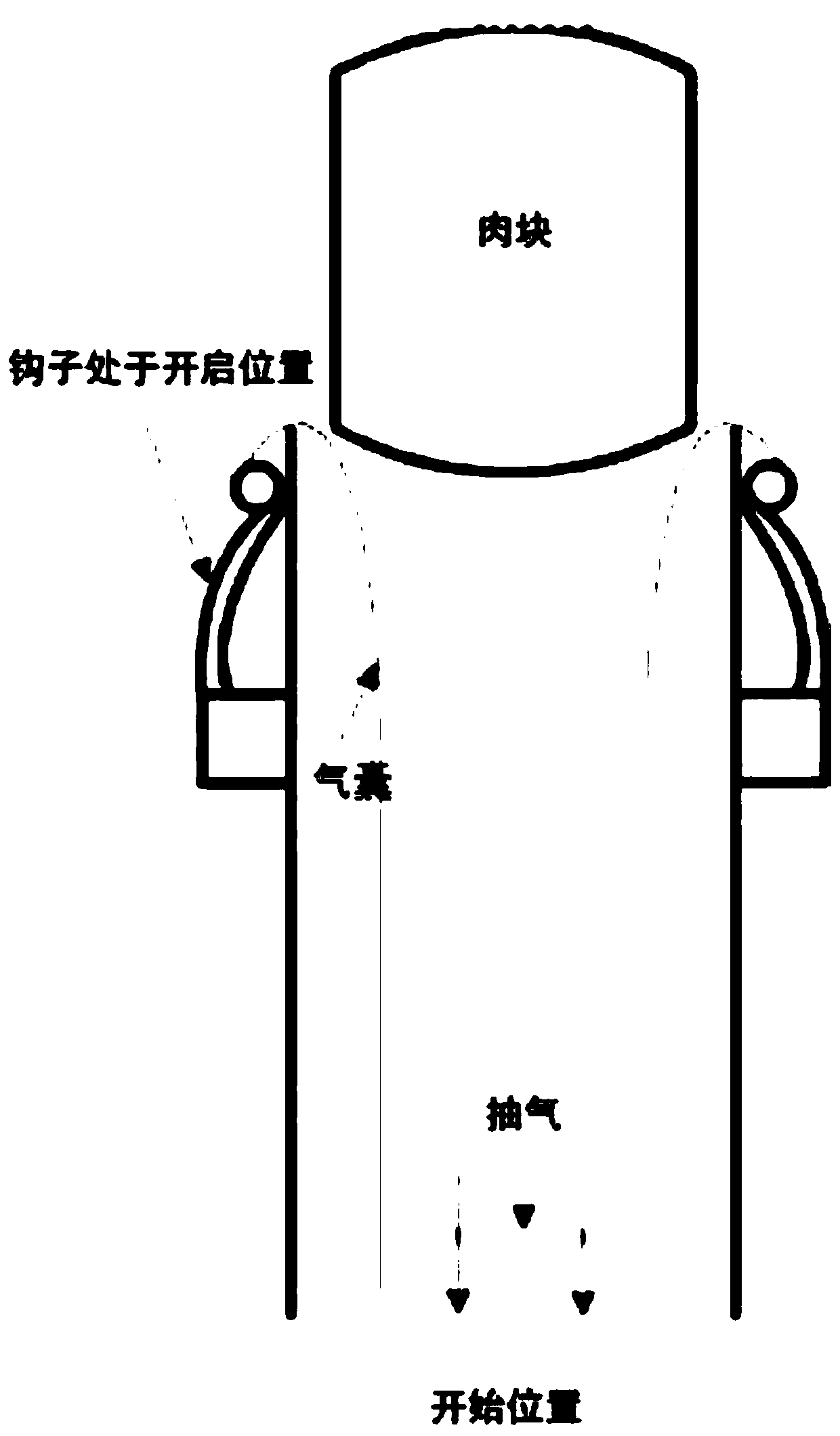

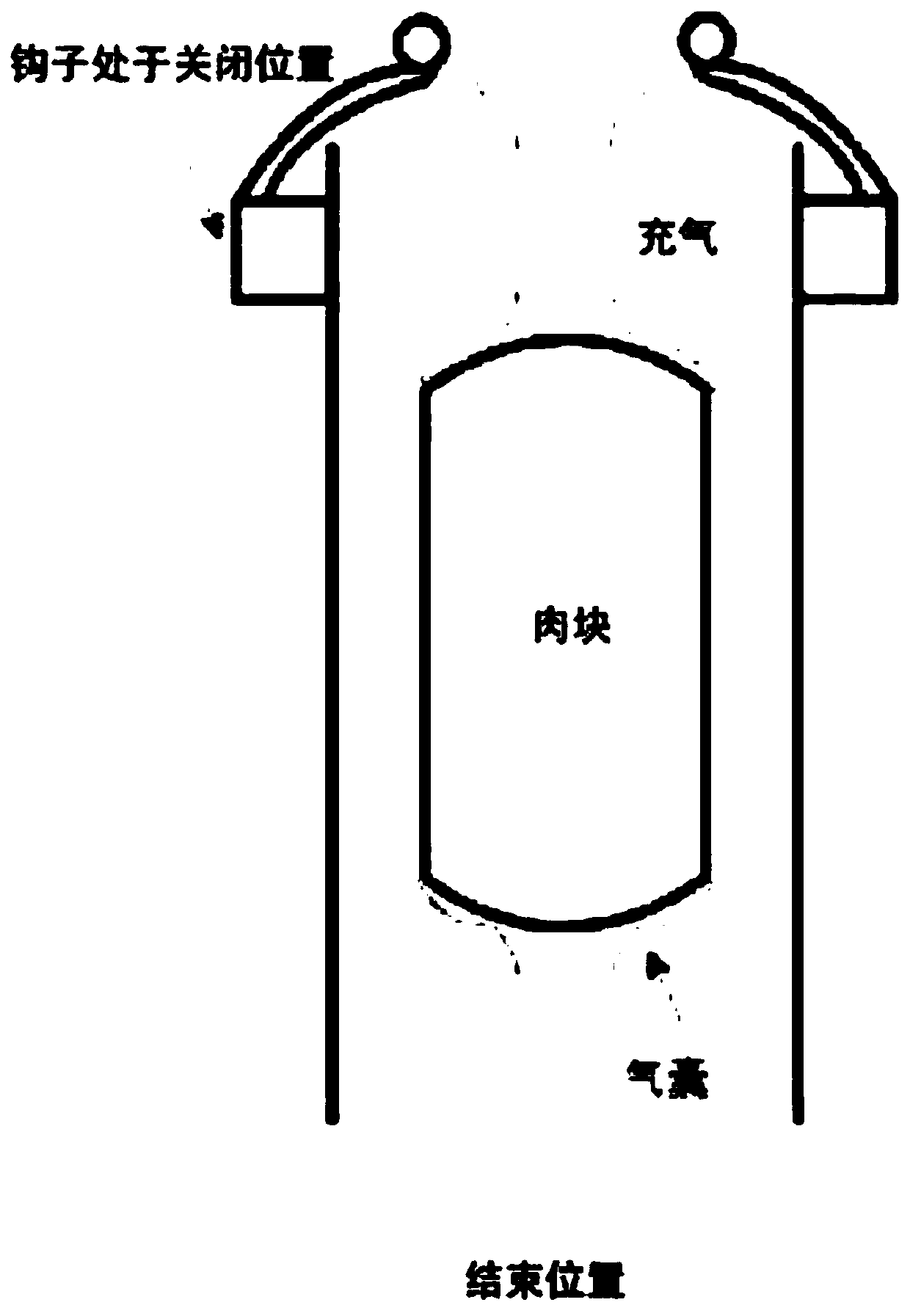

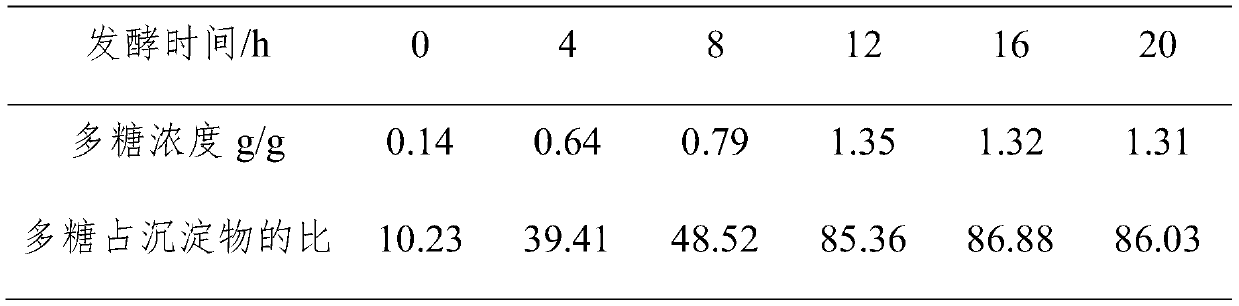

[0058] Add pork neck meat into flour and soak for 3 minutes to remove blood, wash and slice into slices with a thickness of 2 cm, then add 1.5% rice protein by weight and 0.15% transglutaminase (w / w), mix and stir for 5 minutes before loading Put it into a vacuum polyethylene bag and mix it evenly; After 250MPa ultra-high pressure treatment for 4 minutes at intervals of 3 minutes, a total of 3 treatments; 7 cfu / g Lactobacillus bulgaricus bacterial suspension, the smear thickness is 0.5mm, cultivated under the condition of 37 ℃ for 14h at a temperature, then add 0.8% NaCl, 0.015% sodium caseinate, 15% of its total weight after fermentation % ice water mixed evenly, low temperature vacuum tumbling for 20 minutes; among them, the ice water temperature is 3 ℃, the drum temperature is 2 ℃, the vacuum degree is 0.10 MPa, the tumbling speed is 8r / min; The pressure is 110psi, the pumping pressure is -12psi, and the interval between pumping and gassing is 1.0s; after that, the Chaetoce...

Embodiment 2

[0068] Soak the pork neck in flour for 3 minutes to remove the blood, wash and slice the slices to a thickness of 1 cm, then add 2.0% starch by weight, 1.5% salt, 3.5% sugar, 0.1% monosodium glutamate, 1.3% soy sauce, and 1.8% cooking wine , 1.2% rice protein, 0.1% transglutaminase (w / w) were mixed and stirred for 6 minutes and then put into a vacuum polyethylene bag and mixed and stirred evenly; through 260MPa ultra-high pressure treatment for 3 minutes at intervals of 2.5 minutes, a total of 2 times; after treatment, the surface of the pork neck was smeared with an effective bacterial count of 5×10 7 cfu / g of Lactobacillus bulgaricus suspension, the thickness of the smear is 0.1mm, and the temperature is 39 ° C under the condition of cultivation for 13h, and then add 0.7% NaCl, 0.01% sodium caseinate, 13 % ice water, the temperature of ice water is 2°C, mix evenly, low temperature vacuum tumble for 30min; among them, the drum temperature is 3°C, the vacuum degree is 0.15MPa,...

Embodiment 3

[0078] Soak the pork neck in flour for 3 minutes to remove the blood, wash and slice the slices to a thickness of 3 cm, then add 2.5% starch by weight, 2.0% salt, 3.0% sugar, 0.15% monosodium glutamate, 1.2% soy sauce, and 1.6% cooking wine , 2.0% rice protein, 0.2% transglutaminase (w / w) mixed and stirred for 7 minutes and then packed into a vacuum polyethylene bag and mixed and stirred evenly; through 240MPa ultra-high pressure every 3 minutes ultra-high pressure treatment for 3.5 minutes, a total of 3 times; after treatment, the surface of the pork neck was smeared with an effective bacterial count of 5×10 7 cfu / g of Lactobacillus bulgaricus suspension, wherein the thickness of the smear is 0.5mm, cultured at a temperature of 42°C for 12h, and then added 0.75% NaCl, 0.012% sodium caseinate, 14% ice water, mixed evenly with ice water temperature at 1°C, low-temperature vacuum tumble for 25 minutes; among them, the drum temperature was 4°C, the vacuum degree was -0.08MPa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com