Besonance sensor for measuring liquid density

A liquid density and sensor technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of affecting the accuracy of measurement, difficult to work stably and reliably, and achieve the effect of small heat affected zone, simple mode shape, and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

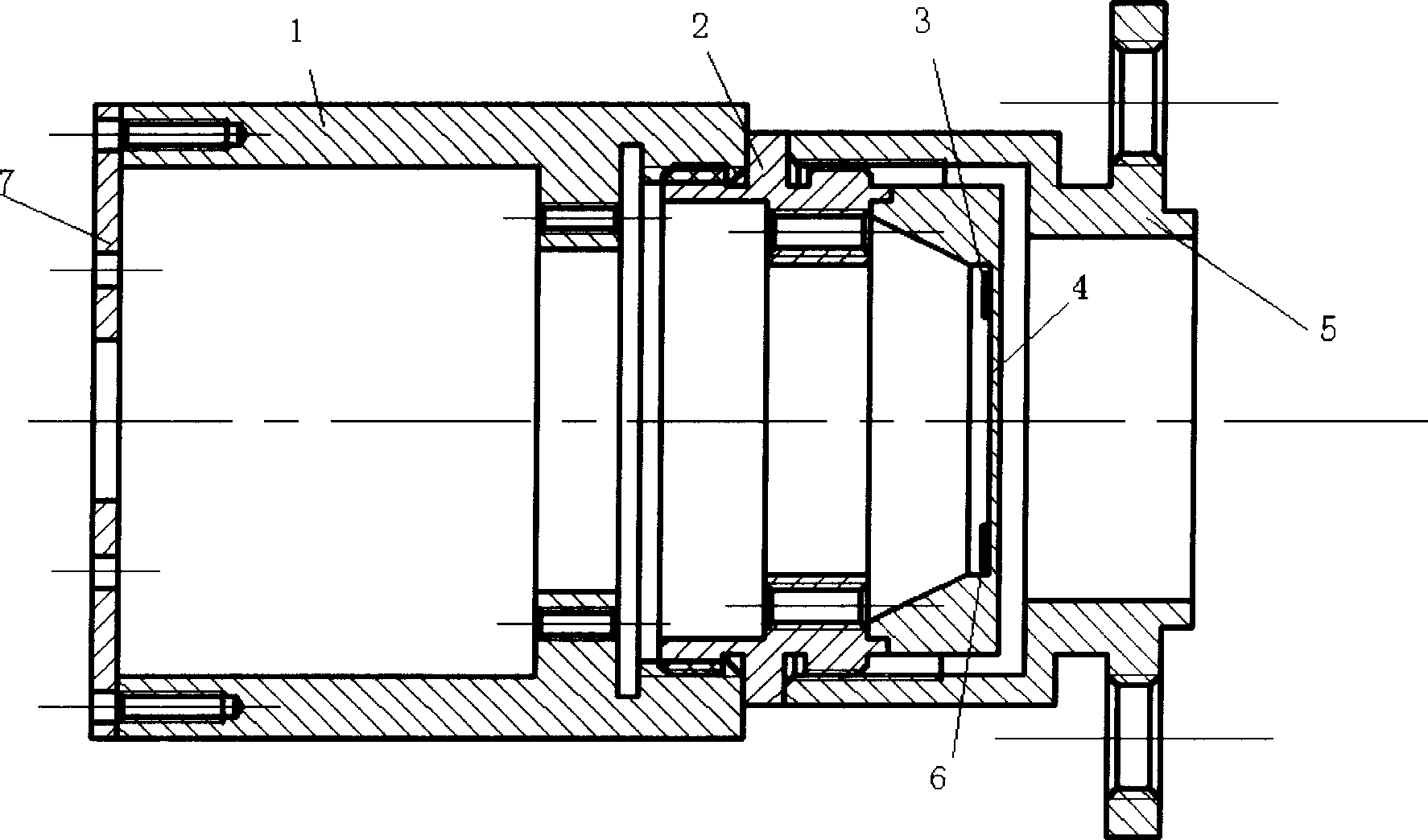

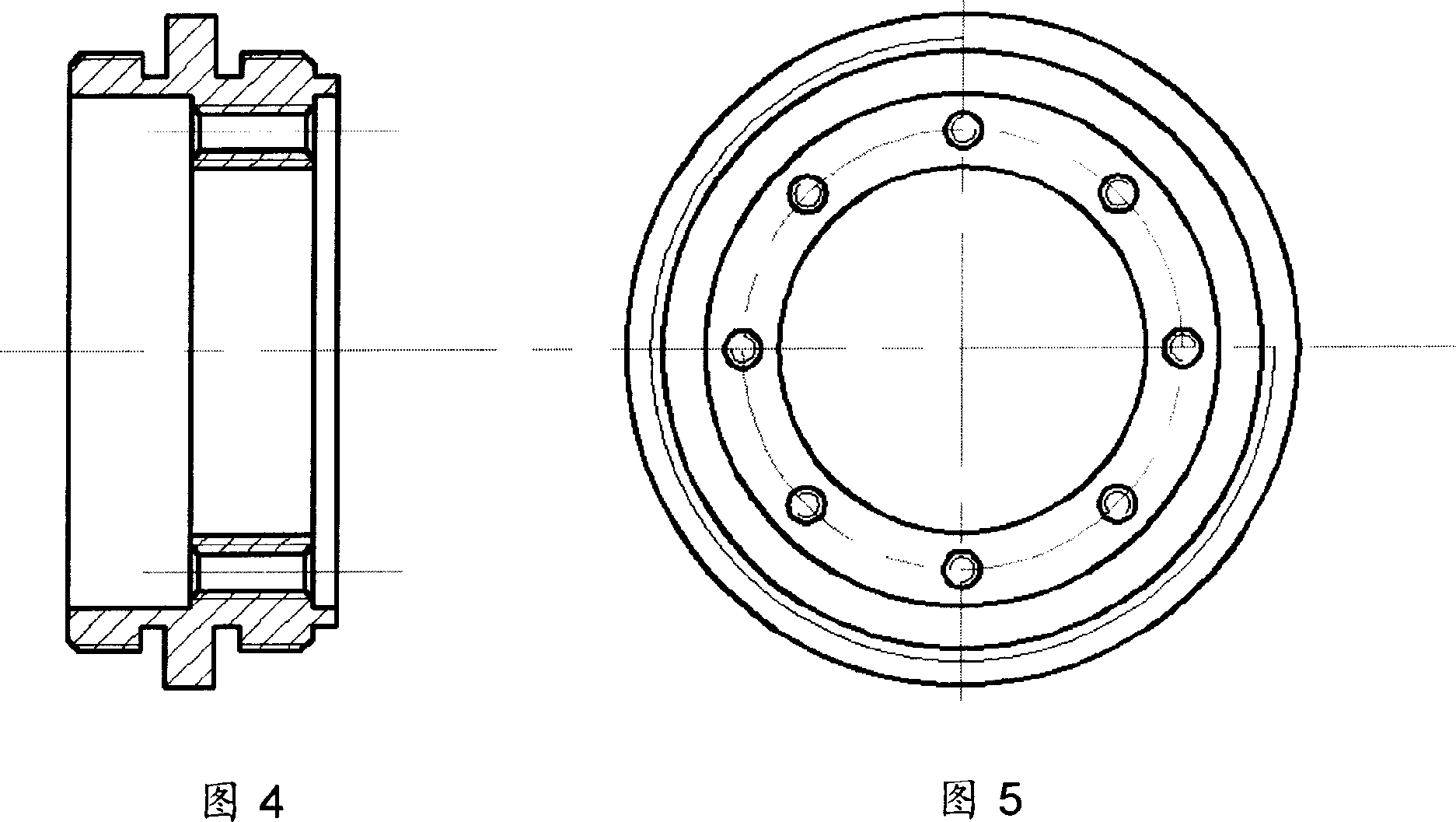

[0020] Such as Figure 1-10 As shown, the present invention consists of a diaphragm circuit box 1, a diaphragm base 2, a piezoelectric exciter 3, a diaphragm 4, a diaphragm box flange structure 5, a piezoelectric vibration pickup 6 and an end cover 7, Diaphragm 4 and diaphragm base 2 are welded together by vacuum electron beam welding, diaphragm base 2 and diaphragm box flange structure 5 are connected by thread, diaphragm base 3 and diaphragm circuit box 1 are connected by thread , The piezoelectric vibrator 3 and the piezoelectric pickup 6 are pasted on the same side of the diaphragm, which is different from the previous diaphragm density sensor. The measured liquid is connected with the liquid container through the flange connection 5 of the box body, and the end cover 7 covers the diaphragm circuit box 1 .

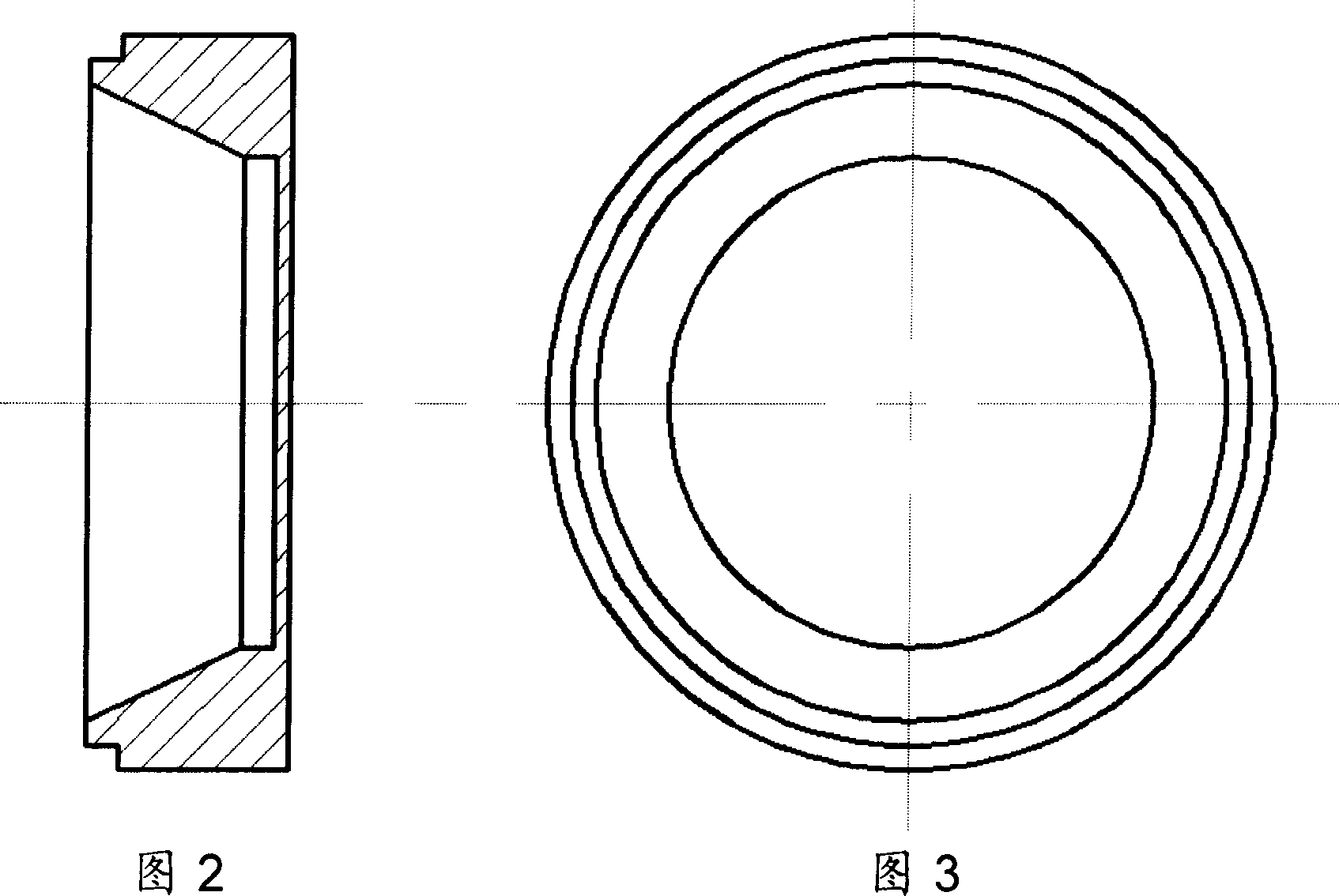

[0021] As shown in Figures 2 and 3, the diaphragm 4 is the most important part of the sensor, so the elastic alloy steel 3J53 is used, and its processing quality dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com