Resonant cylinder type liquid density sensor

A liquid density and sensor technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult cleaning and maintenance, pollution, affecting the reliability of measurement accuracy, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

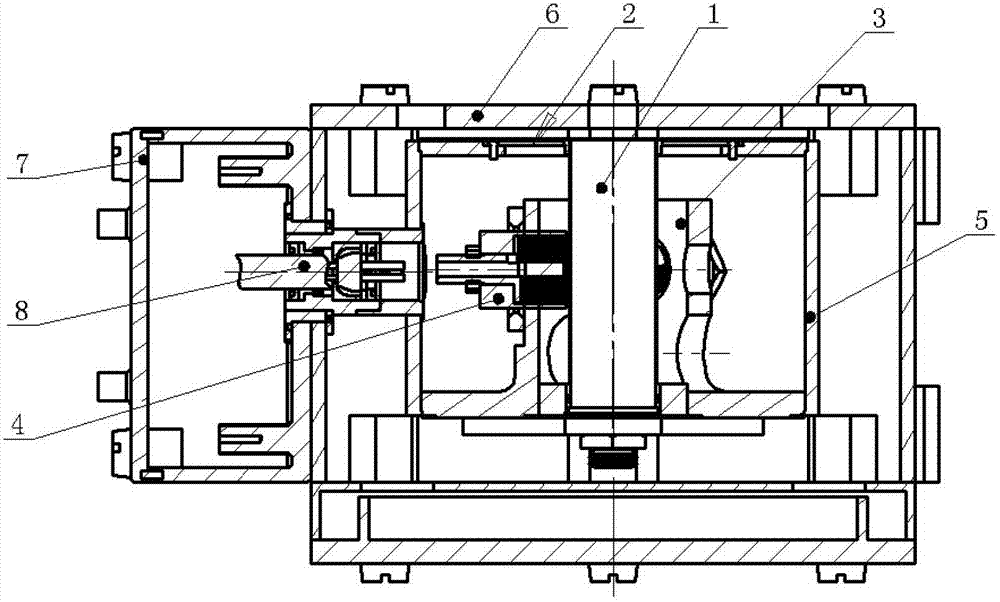

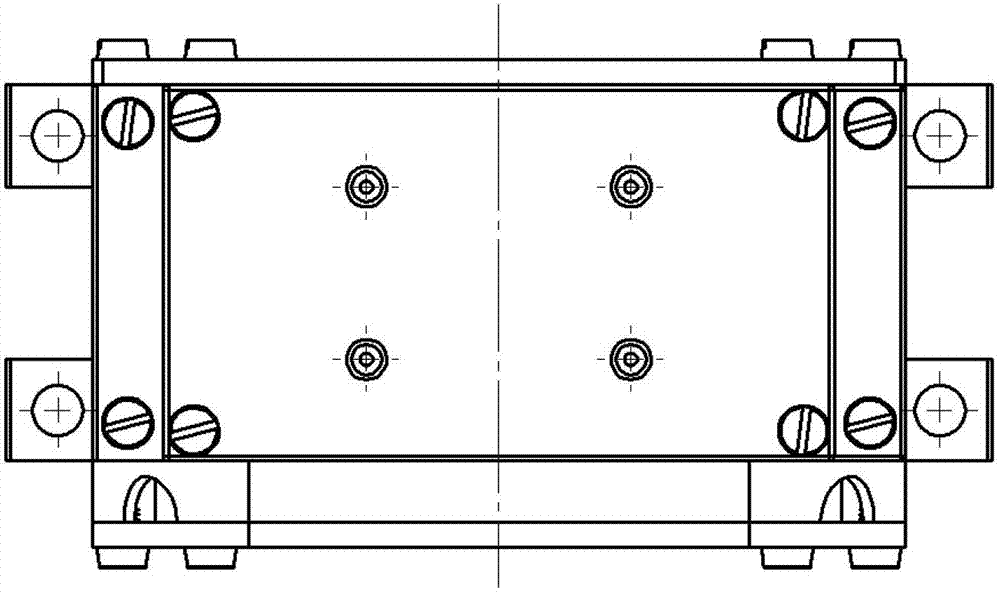

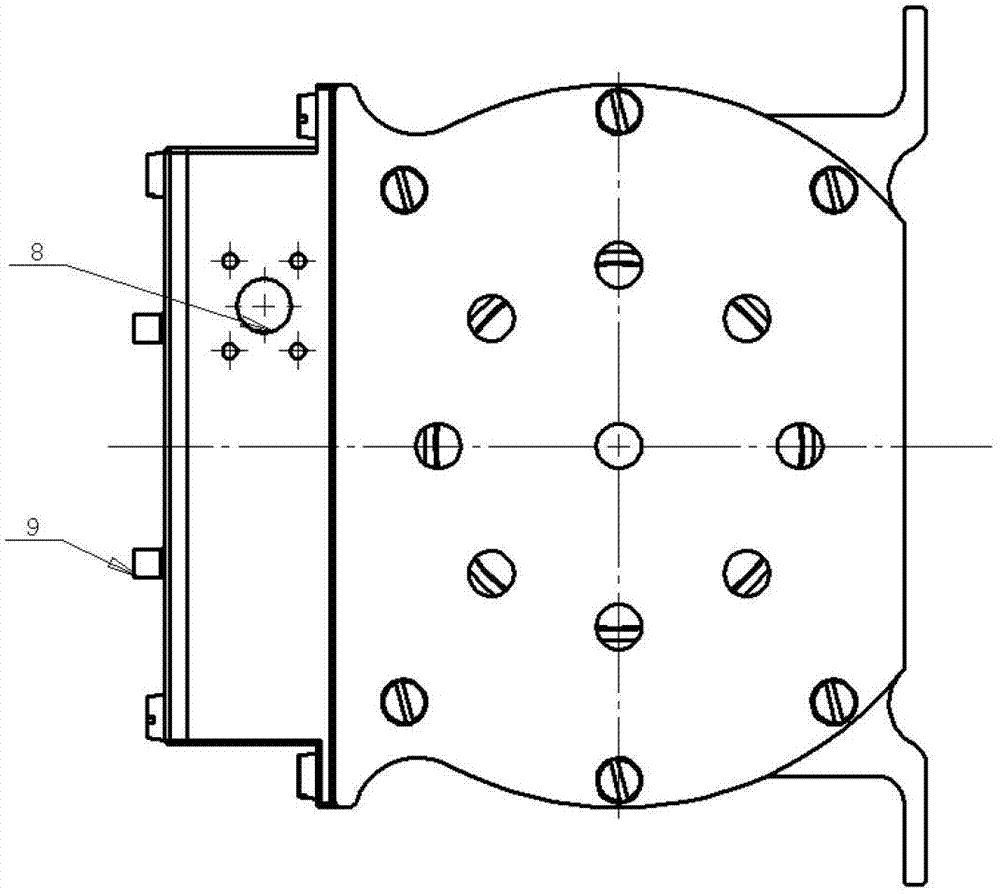

[0033] The technology of the present invention solves the problem: Overcoming the deficiencies in the prior art, a kind of resonant cylinder type liquid density sensor is designed, the density sensor adopts the working mode m=1, n=3 when working, and only the inner side of the resonant cylinder is placed to be measured In the liquid, the excitation and pickup coils are also isolated from the liquid under test, which can measure the density of the liquid under test in real time and online, and also has the additional function of detecting whether the liquid under test is contaminated. The resonant density sensor has high measurement accuracy, stability and reliability, simple structure, small volume, easy installation and maintenance, and can be used under harsh conditions.

[0034] The technical solution of the present invention: a resonant cylinder type liquid density sensor, which is composed of a resonant cylinder, a diaphragm, a coil base, an excitation coil, a vibration pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com