Apparatus on a carding machine for processing textile fibres, for example cotton, synthetic fibres and the like, with a cylinder

一种纺织纤维、梳理机的技术,应用在纤维处理、除毛刺装置、纺织品和造纸等方向,能够解决相关元件热量增加、高纤维负载、针布带堵塞等问题,达到磨损小、均匀梳理、纤维的分布均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

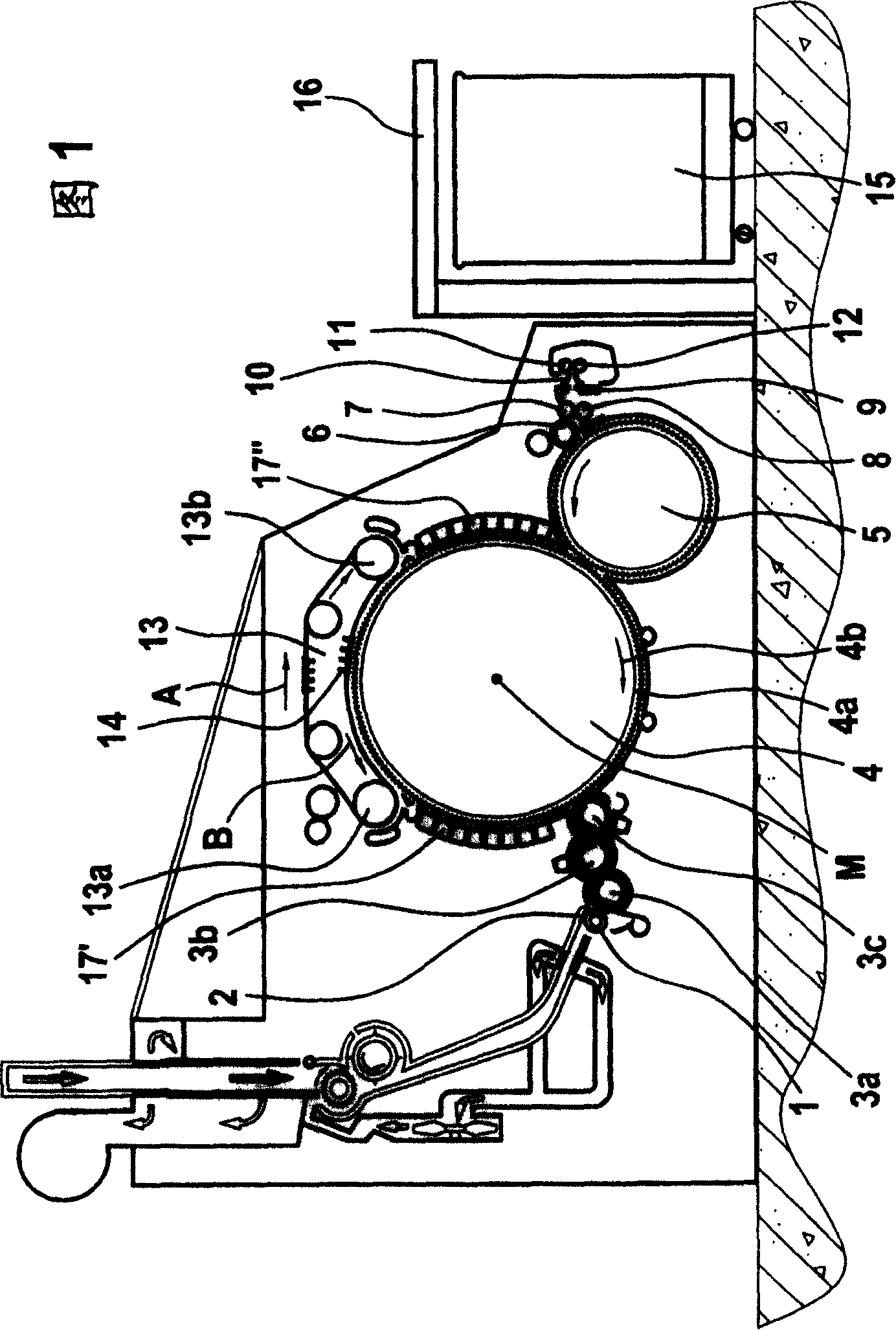

[0022] Fig. 1 shows a kind of carding machine, for example, Trützschler flat card machine TC03, has feed roller 1, feed plate 2, licker-in roller 3a, 3b, 3c, cylinder 4, doffer 5, stripping roller 6, Nipping rollers 7, 8, web guide elements 9, web horn 10, delivery rollers 11, 12, revolving card flats 13 with card flat guide rollers 13a, 13b and card flat strips, and strip Barrel 15 and coiler 16. The direction of rotation of the rollers is shown by correspondingly curved arrows. The letter M represents the center (axis) of the cylinder 4. Reference numeral 4a designates the clothing of the cylinder 4 , and 4b designates the direction of rotation of the cylinder 4 . The device 17' according to the invention is arranged in a fixed position between the licker-in roller 3c and the rear card flat guide roller 13a, and the device 17" according to the invention is arranged between the front card flat guide roller 13b and the doffer 5 The fixed position between. Arrow A indicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com