Instrument for quantitative analysing micro-alkyne in C5 fraction and its analysing method

A C5 fraction and quantitative analysis technology, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve problems such as complex gas paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

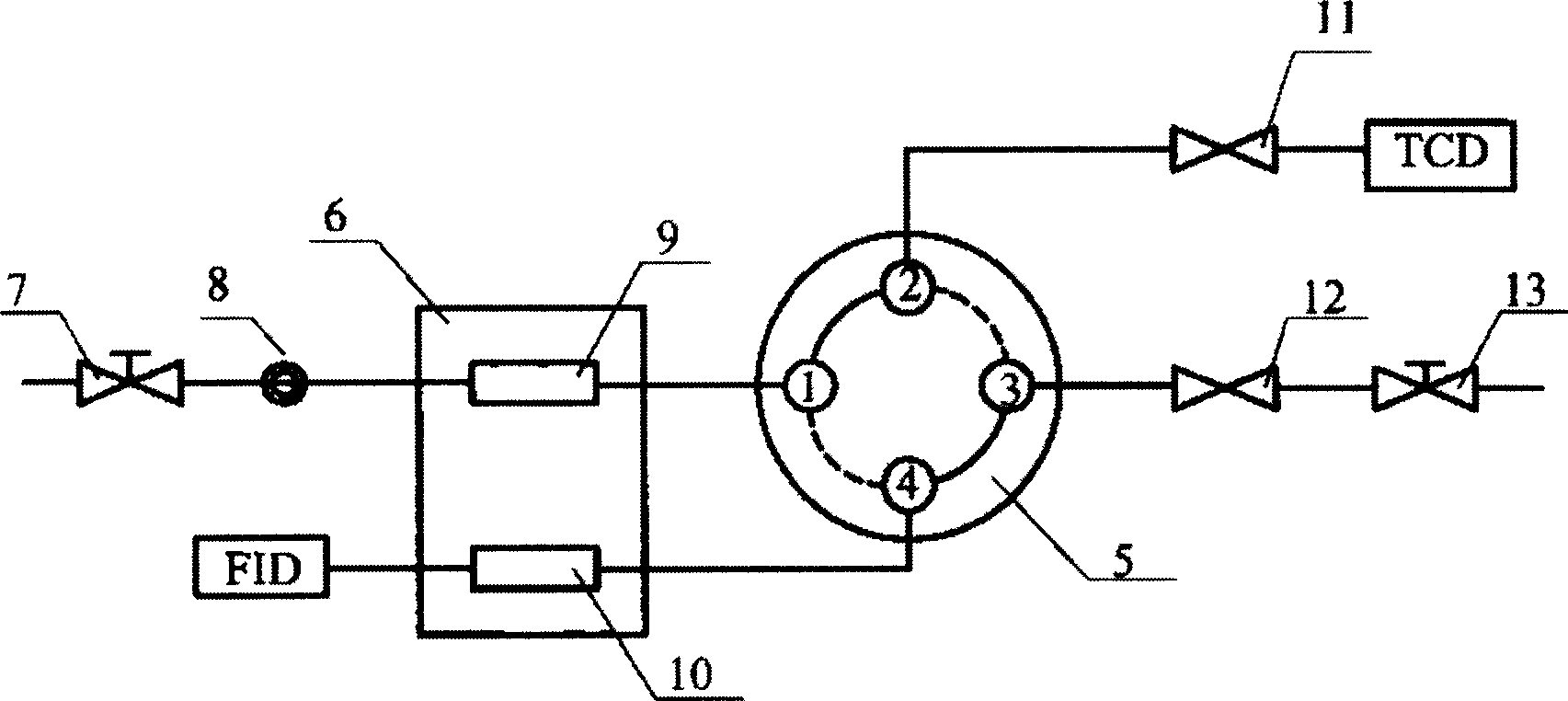

[0047] Combine below figure 1 Further explain the gas chromatography analysis instrument of the present invention.

[0048] The gas path of Beifen 3420 gas chromatograph is modified to obtain the analytical instrument of the present invention.

[0049] like figure 1 As shown, the analytical instrument of the present invention includes a pressure stabilizing valve 7 of a sample injector 8, a sample injector 8, a column box 6, a first packed column 9, a second packed column 10, a four-way valve 5, and an air resistance 11 , gas resistance 12, pressure regulator valve 13, hydrogen flame detector and thermal conductivity detector, four ports 1, 2, 3 and 4 are provided on the four-way valve 5.

[0050] The pressure stabilizing valve 7 is connected to the injector 8, the first packed column 9 and the second packed column 10 are placed in the column box 6, one end of the packed column 9 is connected to the injector 8, and the other end is connected to the interface 1, One end of t...

Embodiment 2

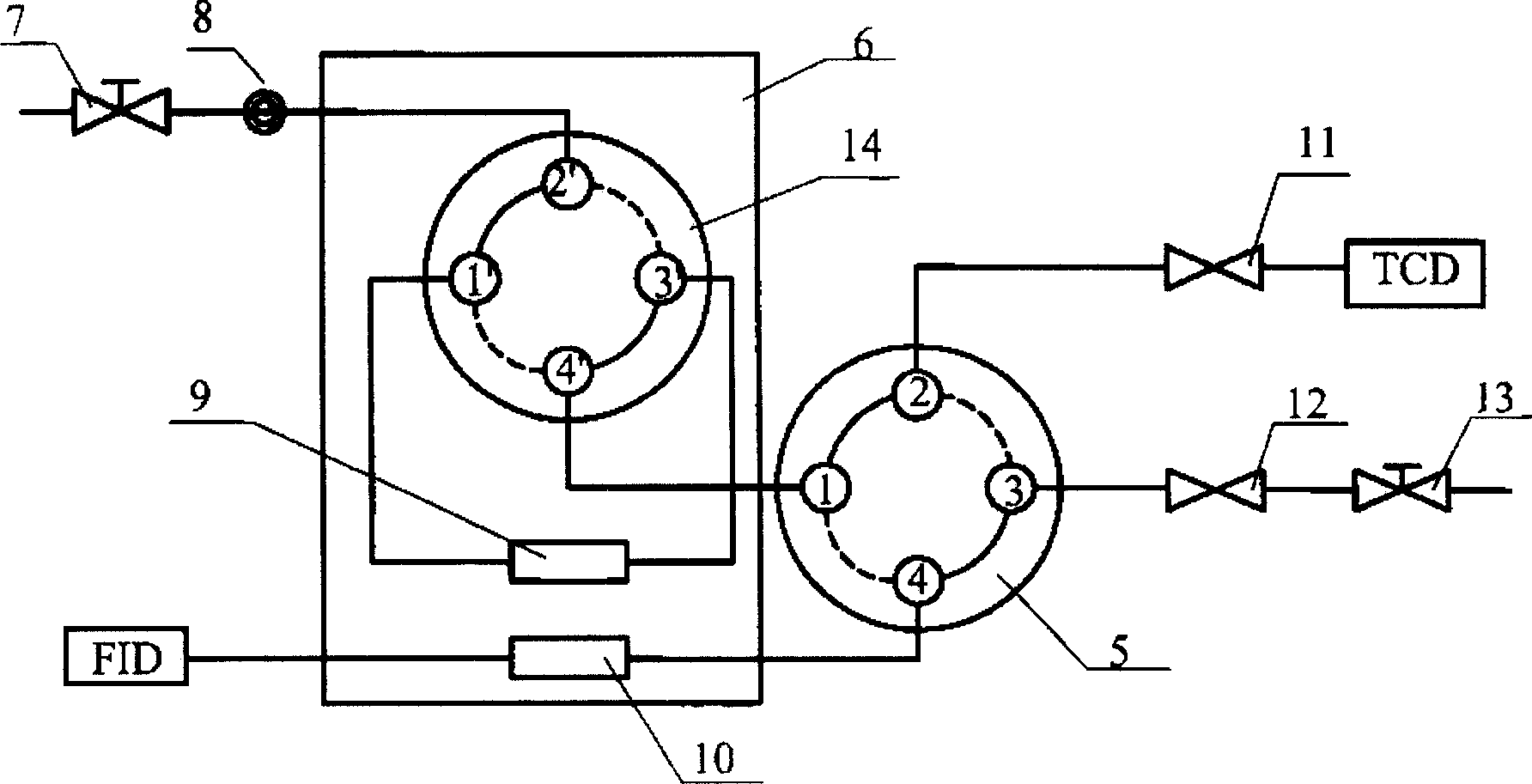

[0057] Combine below figure 2 The analytical instrument of the present invention is further explained.

[0058] The gas path of Beifen 3420 gas chromatograph is modified to obtain the analytical instrument of the present invention.

[0059] like figure 2 As shown, the analytical instrument of the present invention comprises a pressure stabilizing valve 7 of a sampler 8, a sampler 8, a column box 6, a first packed column 9, a second packed column 10, a four-way valve 5, and a four-way valve 14. Air resistance 11, air resistance 12, pressure regulator valve 13, hydrogen flame detector and thermal conductivity detector, there are four interfaces 1, 2, 3 and 4 on the four-way valve 5, and four interfaces on the four-way valve 14 Ports 1', 2', 3' and 4'.

[0060] The pressure stabilizing valve 7 is connected to the injector 8, the packed column 9, the packed column 10 and the four-way valve 14 are placed in the column box 6, the injector 8 is connected to the port 2', and one ...

Embodiment 3

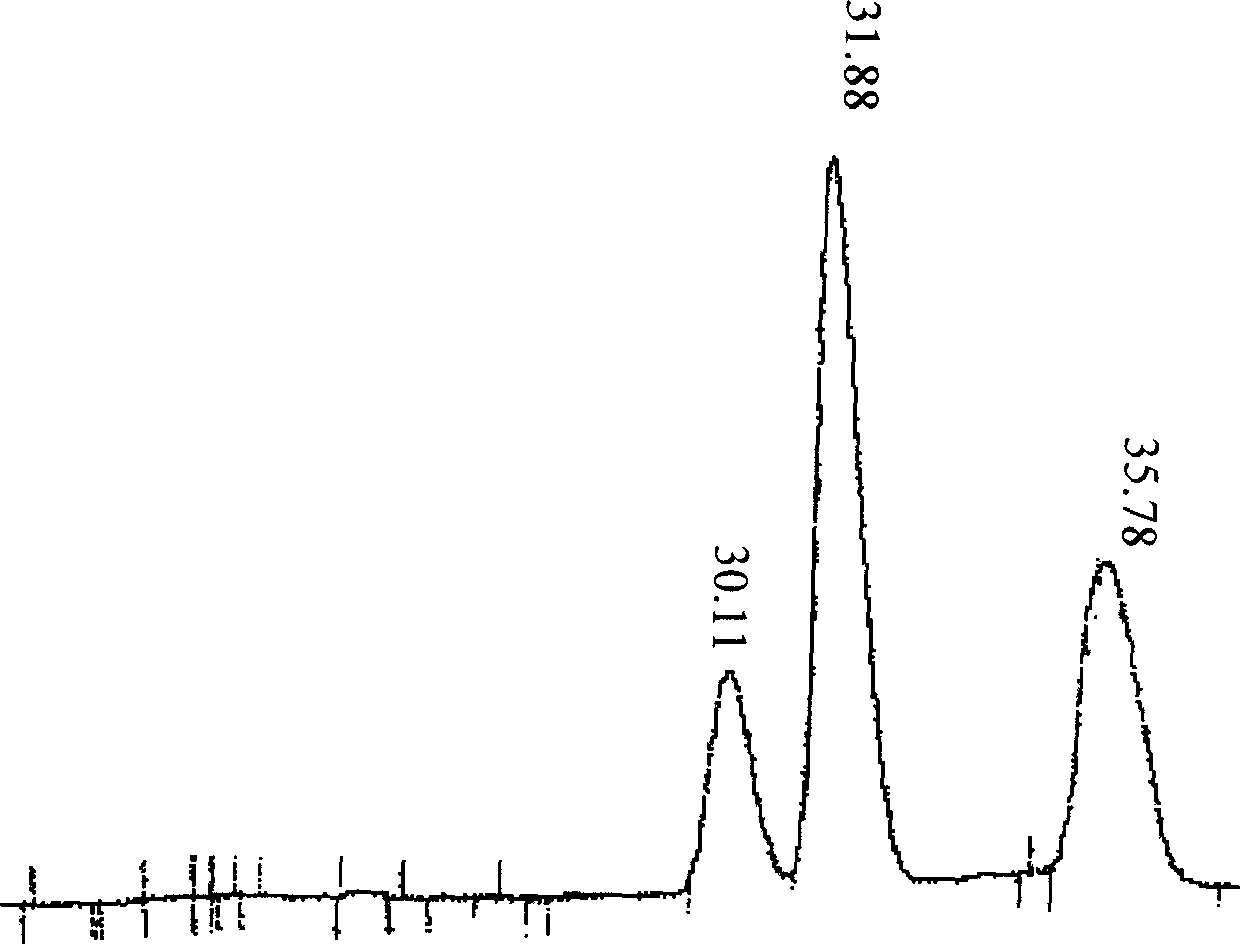

[0067] use figure 1 In the gas circuit shown, the inner diameter of the first packed column is 3 mm, and the column length is 6 meters. The percentage content is 10%; The inner diameter of the second packed column is 3mm, and the column length is 6 meters, and its stationary phase is made up of diethyl azelate stationary liquid and 201 diatomite carrier, and the weight percentage content of stationary liquid is 10 %; The carrier gas is hydrogen, the carrier gas flow rate of the two packed columns is 45ml / min, the flow rate of the auxiliary gas is 45ml / min, the temperature of the injector is 200 ℃, and the temperature of the thermal conductivity detector and the hydrogen flame detector is 200°C.

[0068] In order to illustrate the analytical method of the present invention, the carbon five fraction material shown in Table 3 is analyzed as a sample, which contains a trace amount of alkynes. The injection volume was 2 microliters.

[0069] Component

Content (%) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com