Combined bearing for offset press

A combined bearing and offset printing machine technology, applied in the field of bearings, can solve the problems of inability to realize roller clutch and pressurization, complicate offset printing machine structure, and decline in printing quality, and achieve solid and clear full-page dots, uniform ink color and no ink bars, The effect of continuous adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

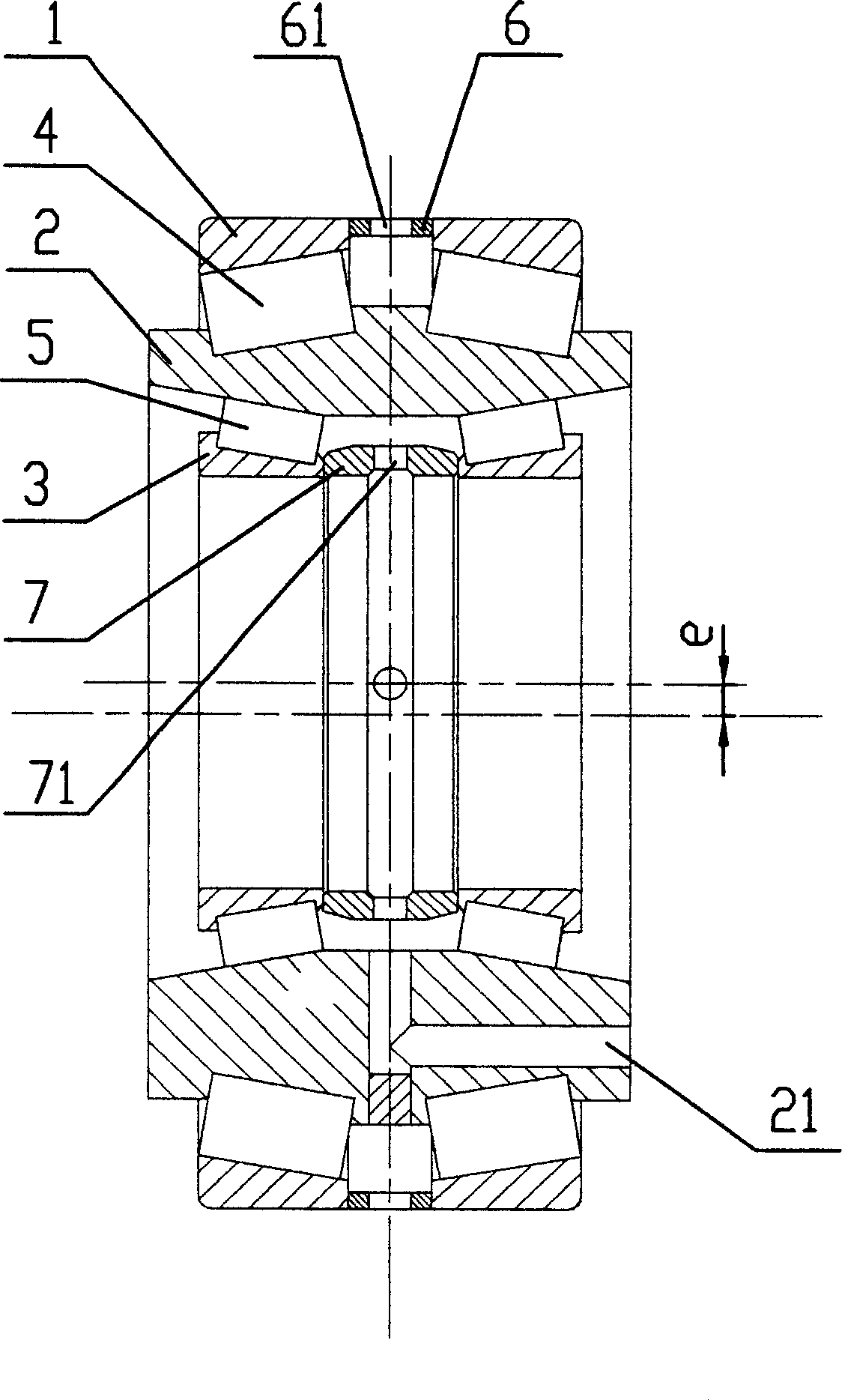

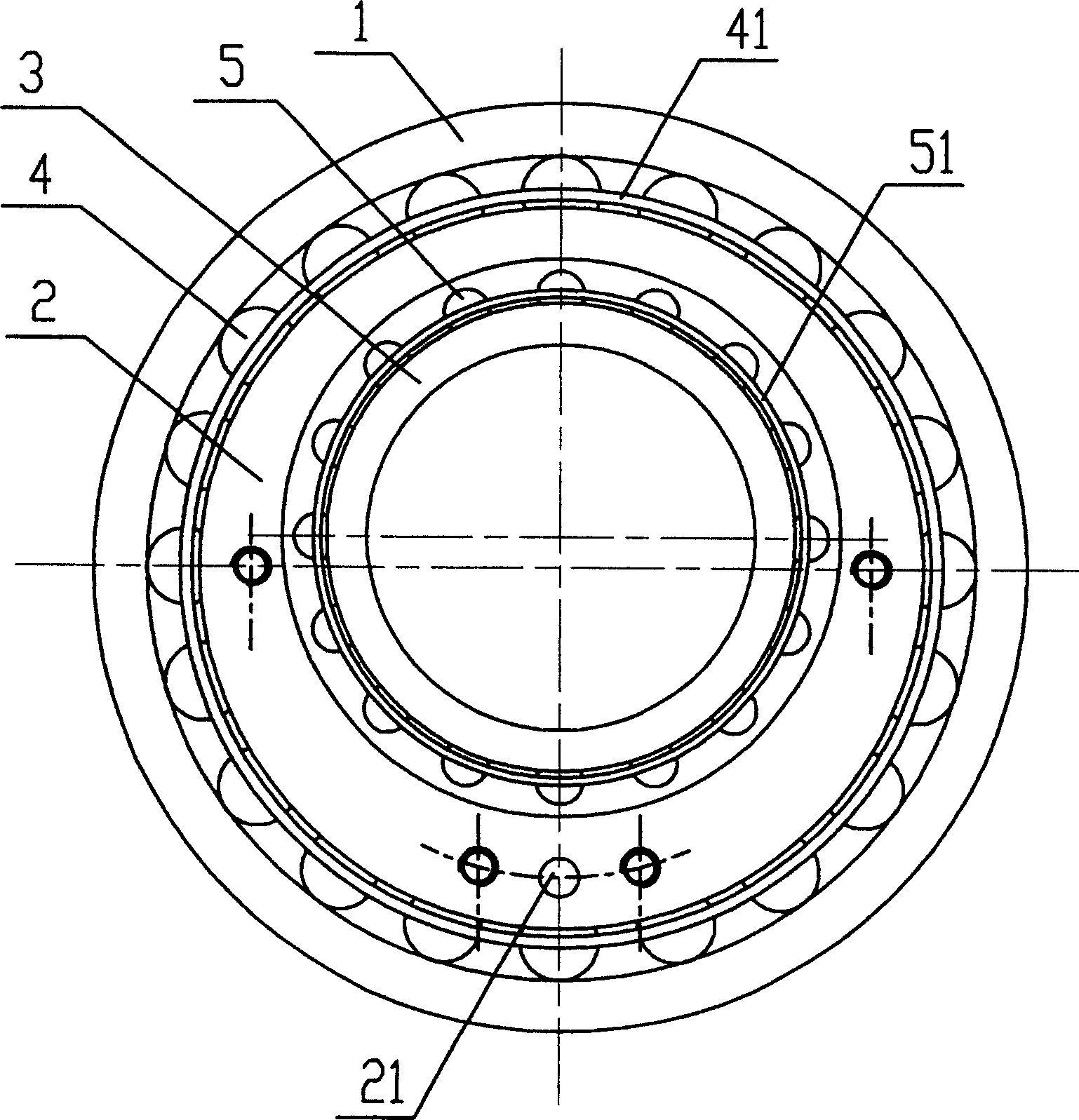

[0009] Such as figure 1 , figure 2 As shown, the combined bearing for offset printing machine includes a double outer ring double row radial tapered roller bearing, and the inner space of the inner ring of the double outer ring double row radial tapered roller bearing is provided with a double inner ring double row Concentric tapered roller bearing, the outer ring of the double inner ring double row radial tapered roller bearing and the inner ring of the double outer ring double row radial tapered roller bearing are of an integrated structure, the double inner ring double The rotation center of the row radial tapered roller bearing is eccentric to the rotation center of the double outer ring double row radial tapered roller bearing.

[0010] The eccentricity is located between the inner circular surface of the outer ring of the double inner ring double row radial tapered roller bearing and the outer circular surface of the inner ring of the double outer ring double row radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com