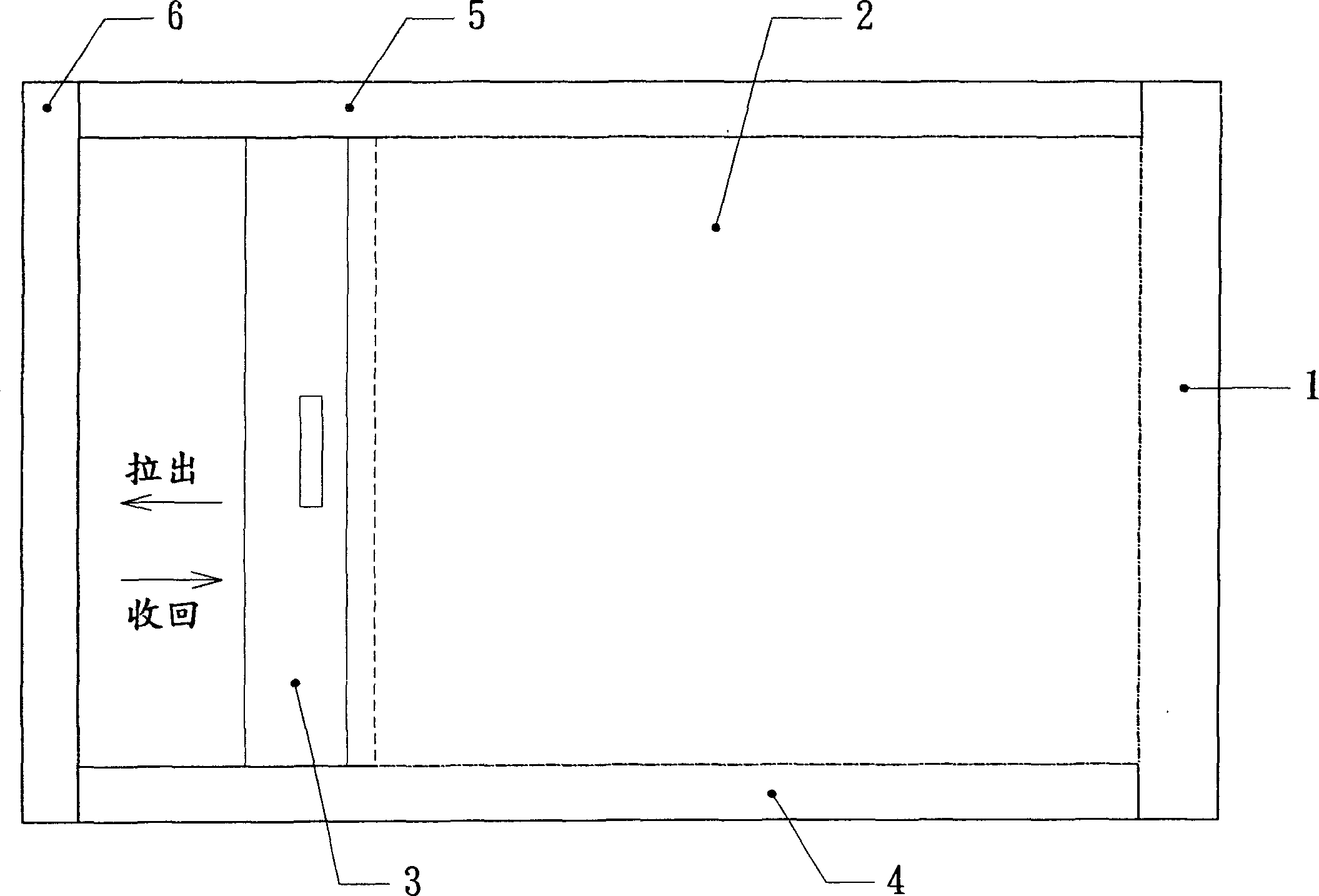

Safety speed reducer for automatic rolling screen window

A technology of invisible screen window and deceleration device, applied in the direction of door/window protection device, window/door, building components, etc., to achieve the effect of improving practicability, safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

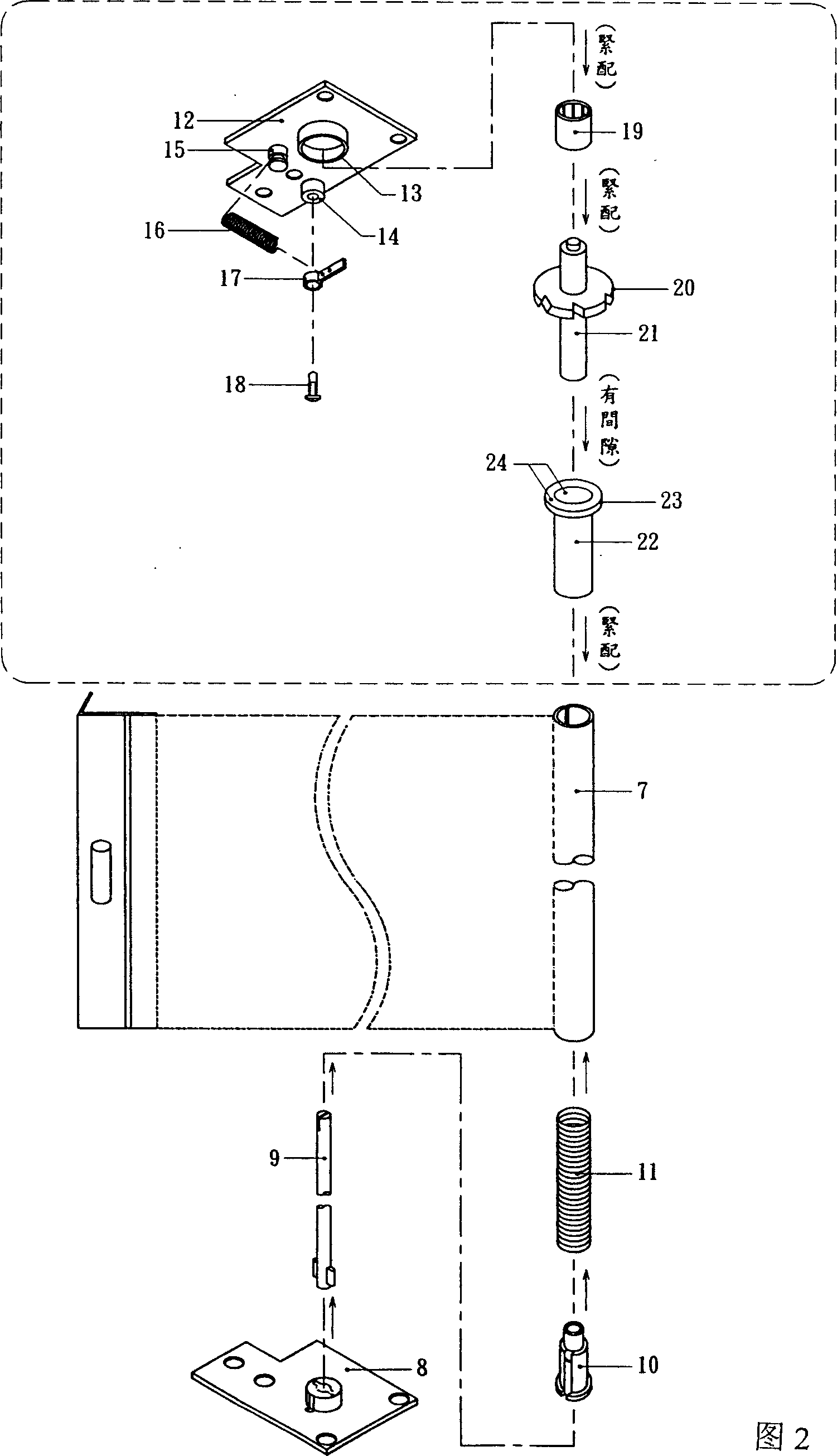

[0011] What Fig. 2 shows is to implement the structural combination of the utility model on an existing automatic invisible screen window.

[0012] A torsion spring (11) is installed in the gauze rolling bar round tube (7). The lower end of the spring (11) is fixedly sleeved on the upper part of the lower plug (10) of the rolling bar round tube. Insert it into the lower plug (10), and there are protrusions on both sides of the lower end to be inserted into the lower plastic plug (8) of the yarn box. The lower plastic plug (8) of the yarn box is a rectangular flat plate (with one corner removed), and Shape is identical with yarn box plastic plug (12).

[0013] The content of the technical solution designed by the present invention is in the upper part of Fig. 2, that is, it is arranged between the yarn box plastic plug (12) and the gauze rolling bar circular pipe (7).

[0014] There is a slight difference between the inner diameter of a section of circular tube-shaped holder (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com