Processing method for strake for leveling boat

A technology of plate row and hull, which is applied to the processing field of plate row for hull leveling, can solve the problems of large floor space, adverse effects of materials, and large investment in plate-rolling and leveling machines, and achieves the effect of saving investment and simplifying road rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The processing method of a flat row of hulls of the present invention will be described below.

[0010] First of all, a flat cement site larger than or equal to the size of the board column is sorted out near the paneling station. According to the maximum plate row size of the parallel mid-hull part of the hull, the plate rows to be rectified after tailor welding are laid flat on the site;

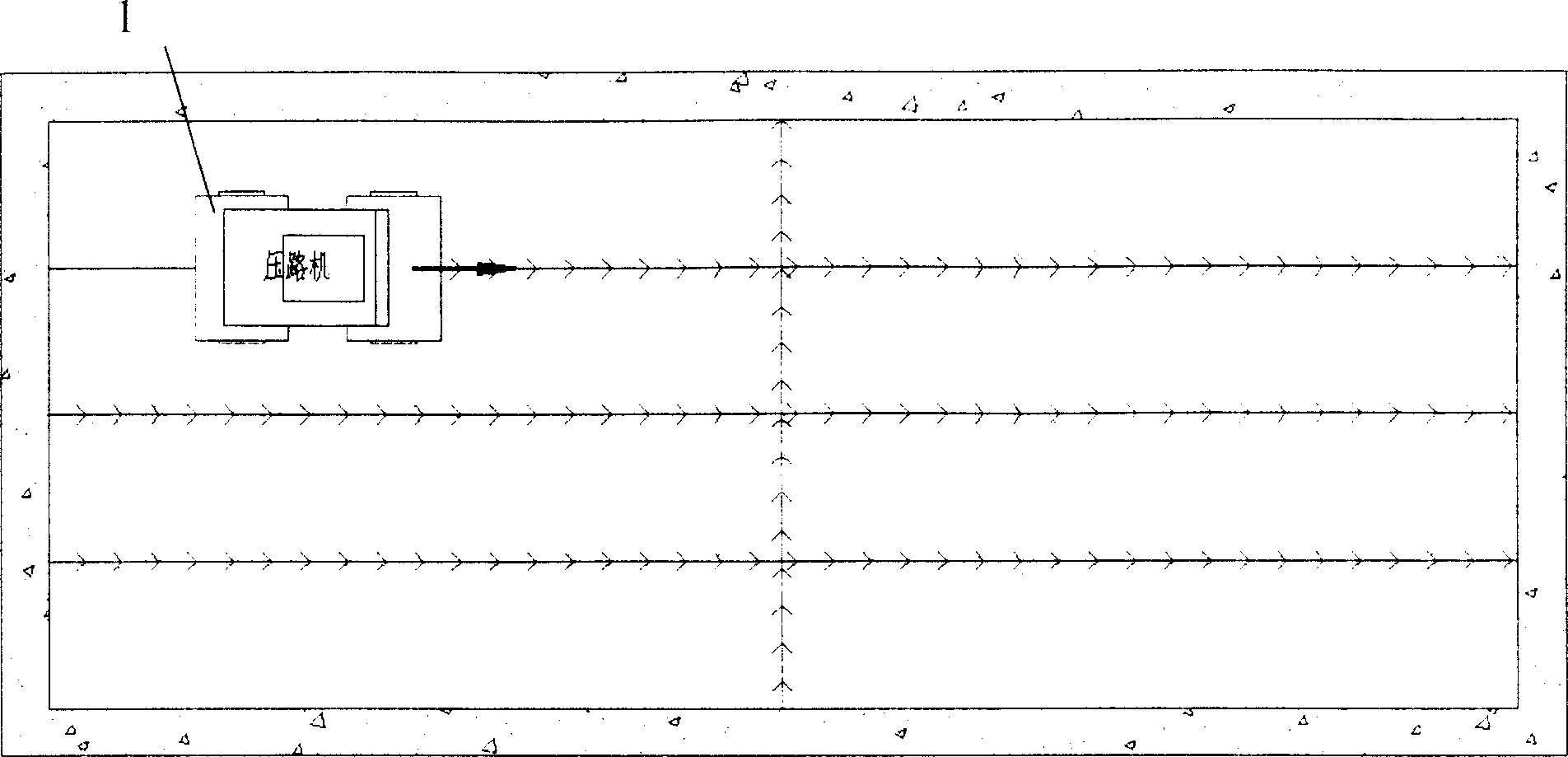

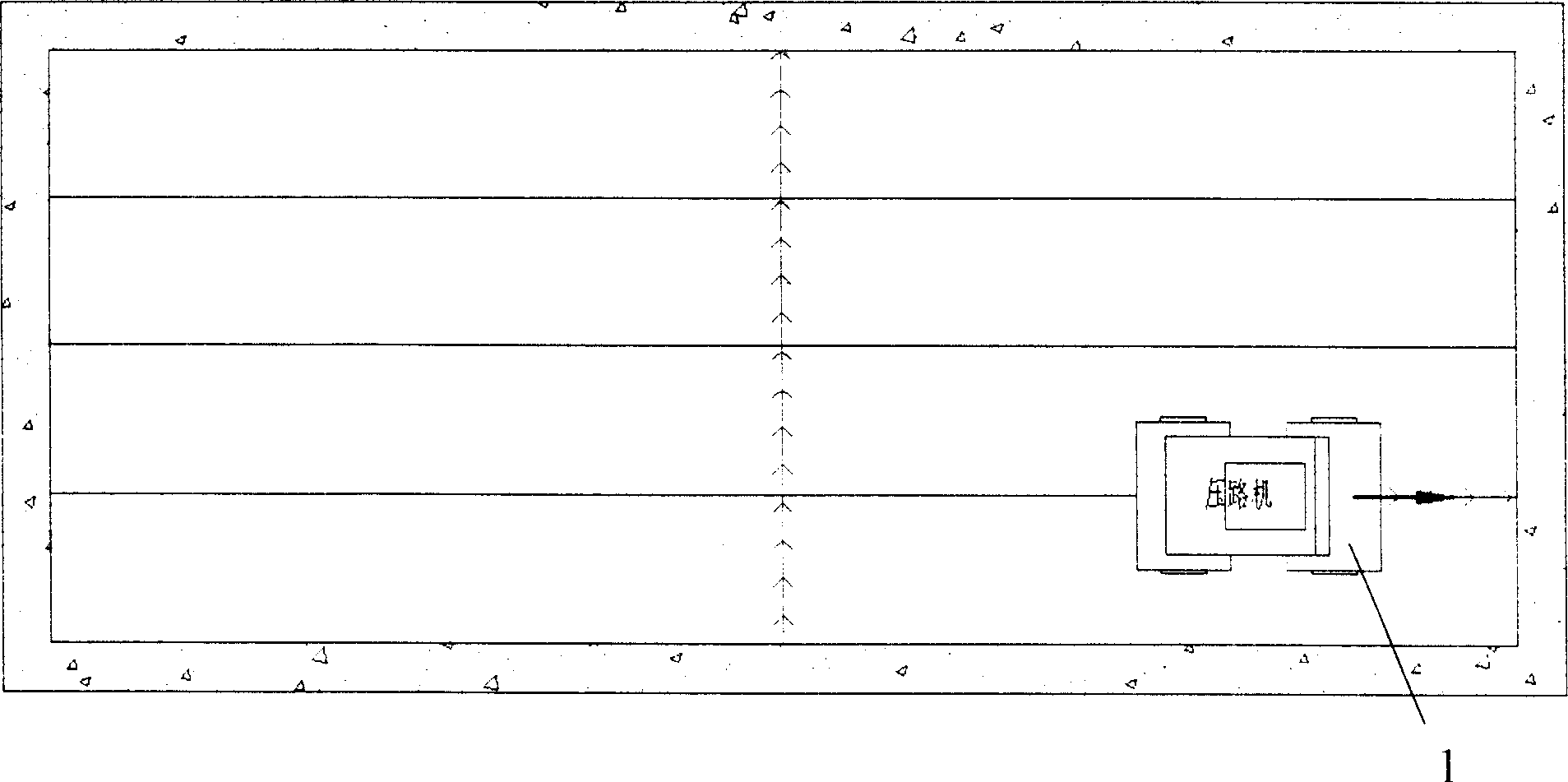

[0011] Then, roll the general road roller 1 (two-wheel or three-wheel, preferably two-wheel) along the weld bead direction of the plate column to be rectified after tailor welding, and generally go back and forth once. Meet the technical requirements of flatness.

[0012] figure 1 , 2 Shown is a schematic plan view of a two-wheeled road roller rolling back and forth. figure 1 For the road roller 1 to carry out rolling along the direction of the plate column welding bead of the rectification treatment, figure 2 Shown is the case where the roller 1 is rolling along the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com