Data acquiring system for controlling system of welder

A technology of data acquisition system and control system, applied in general control system, control/adjustment system, computer control, etc., can solve problems such as interference intrusion into the system, failure to work normally, software operation disorder, etc., and achieve high anti-interference ability, The effect of good stability and good anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

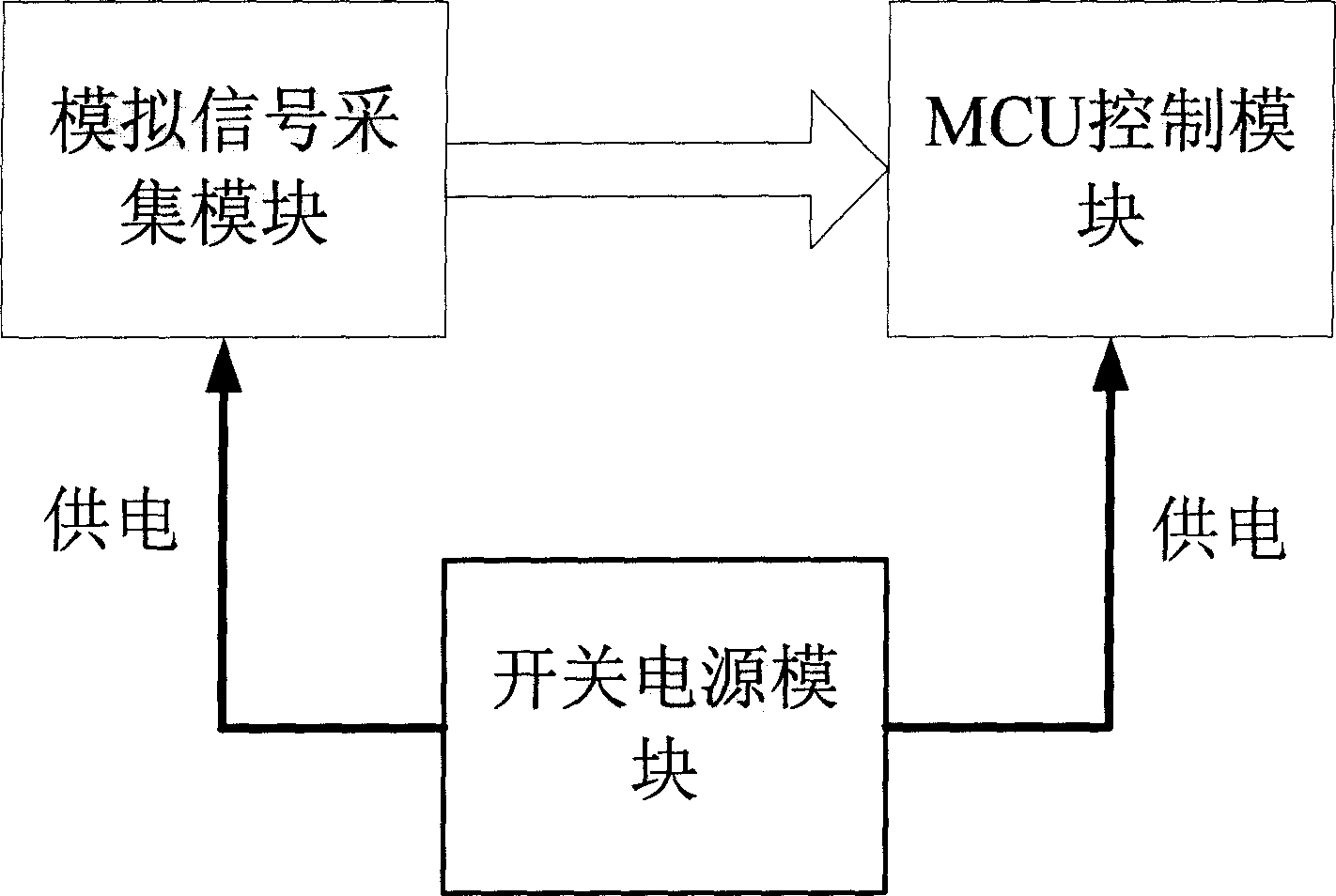

[0018] Such as figure 1 As shown in the system block diagram of the present invention, the data acquisition system used by the welding machine control system of the present invention is characterized in that it includes an analog signal acquisition circuit module, an embedded MCU control system module and a single-chip switching power supply module;

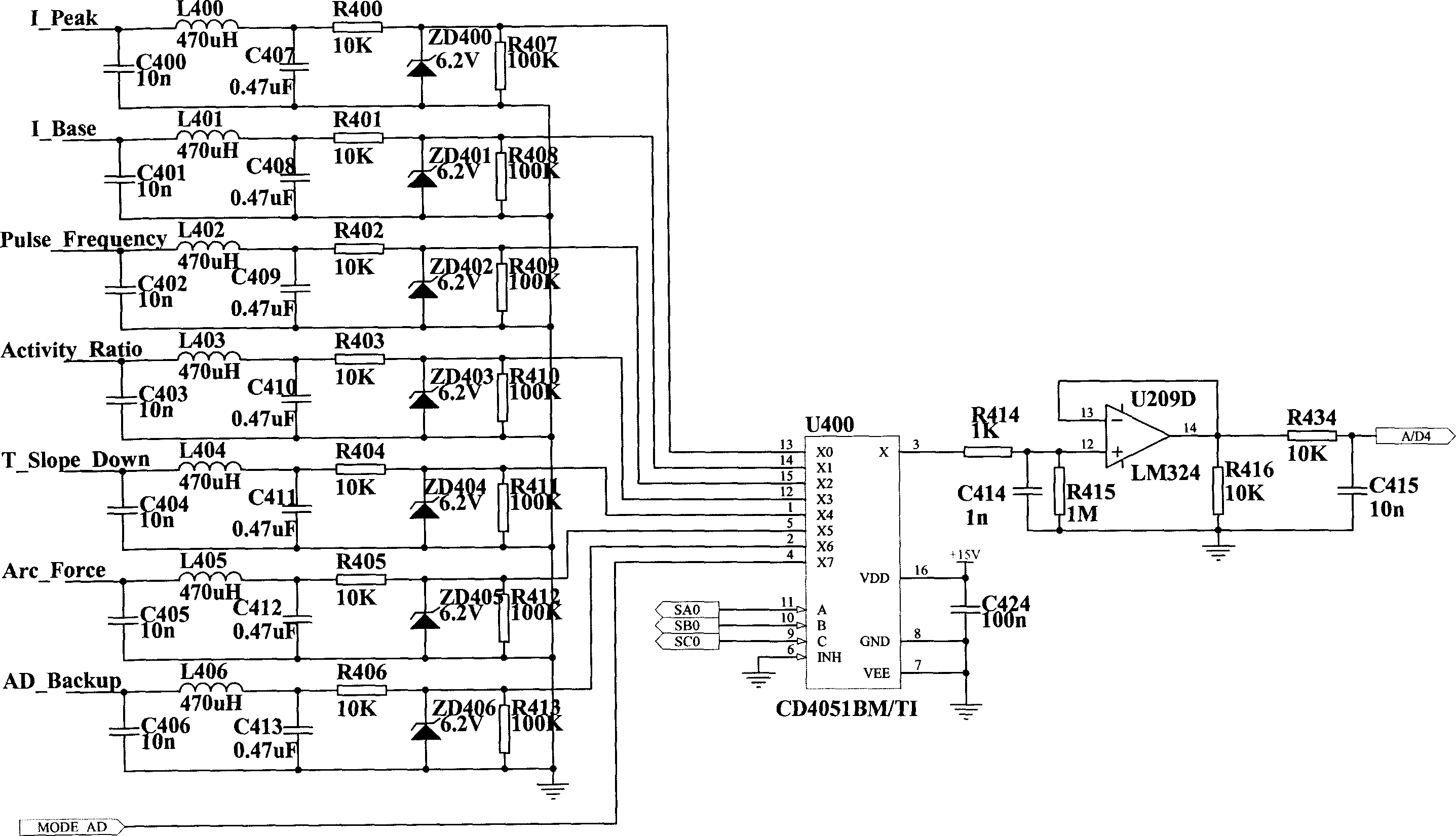

[0019] The output end of the analog signal acquisition circuit module is connected with the input end of the A / D conversion circuit in the embedded MCU control system module, and is used for filtering various analog signals, a voltage divider circuit, and then selecting through a multiplexing circuit After that, it is filtered again and sent to the A / D conversion circuit as a relatively stable input signal;

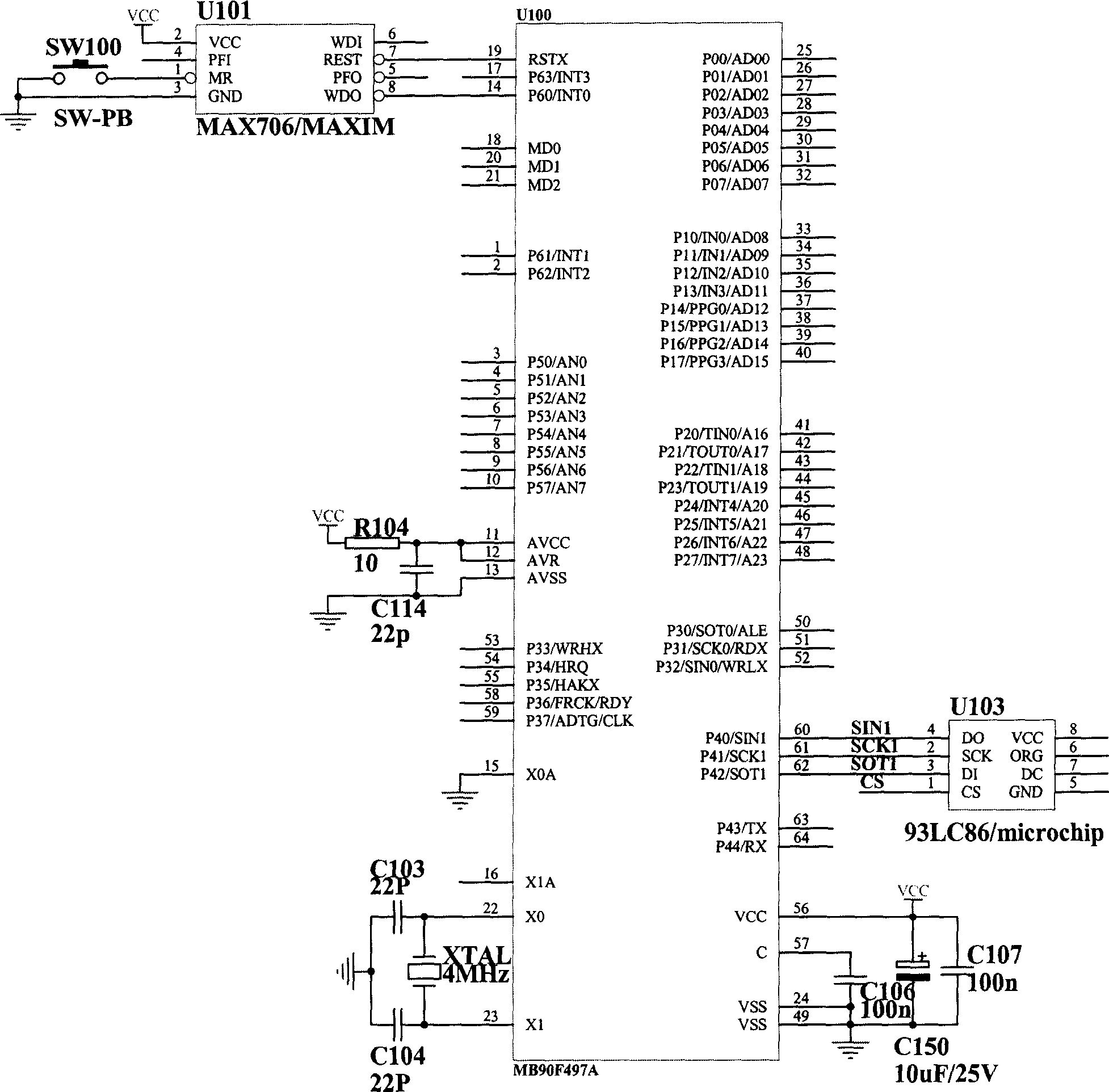

[0020] There is an A / D conversion circuit in the embedded MCU control system module, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com