Bullet mining hydraulic support

A technology of hydraulic support and blasting mining, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of mutual replacement, insecurity, roof leakage, etc., and achieves reduced labor intensity and high frame stability , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

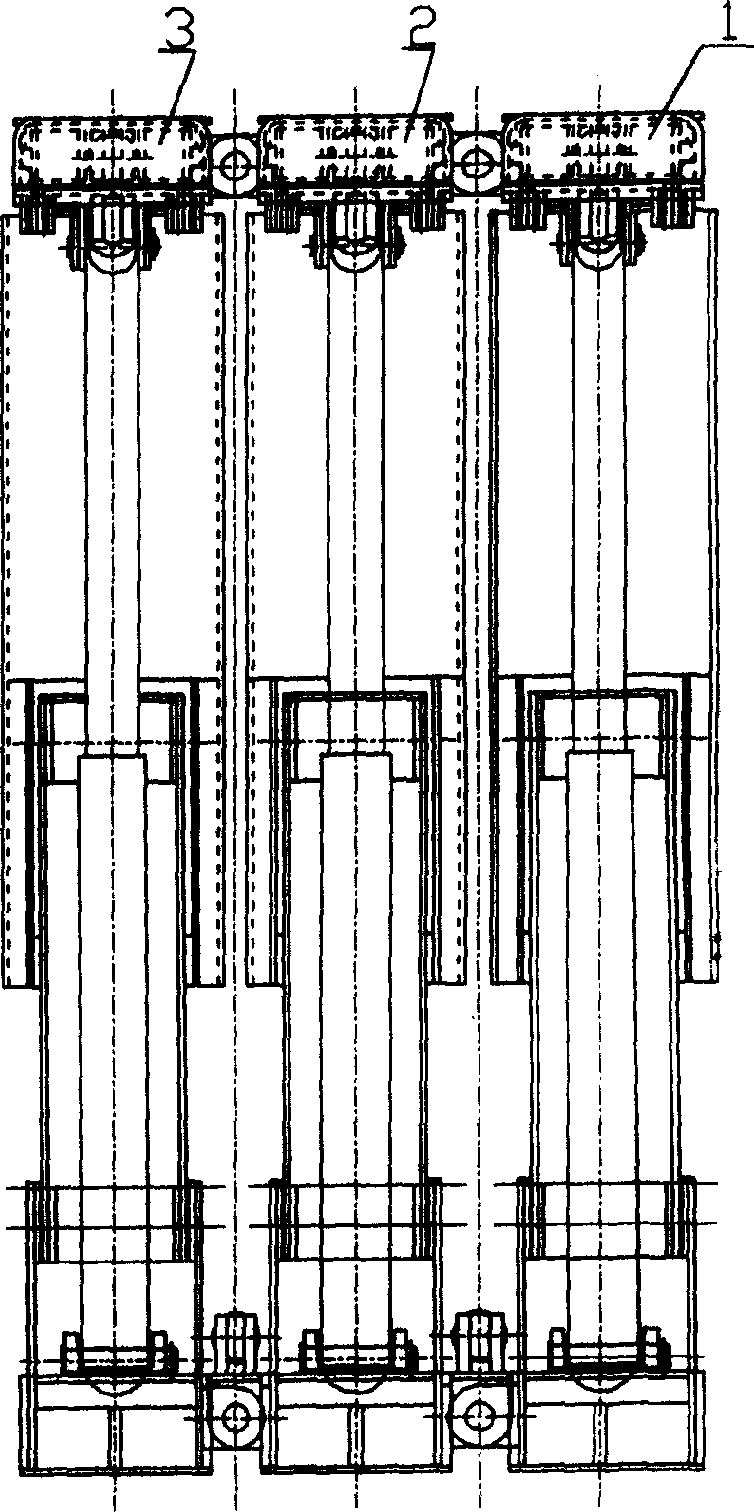

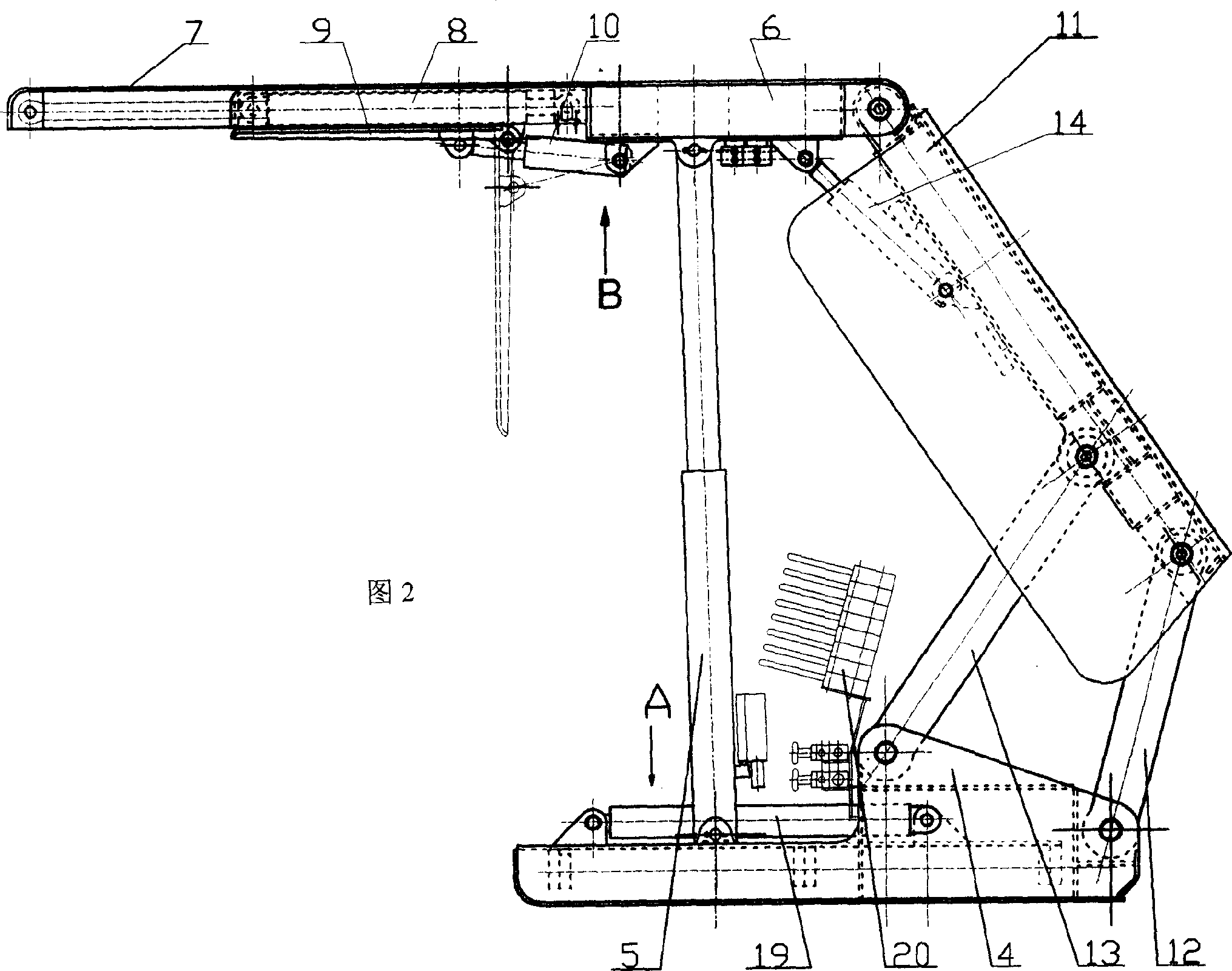

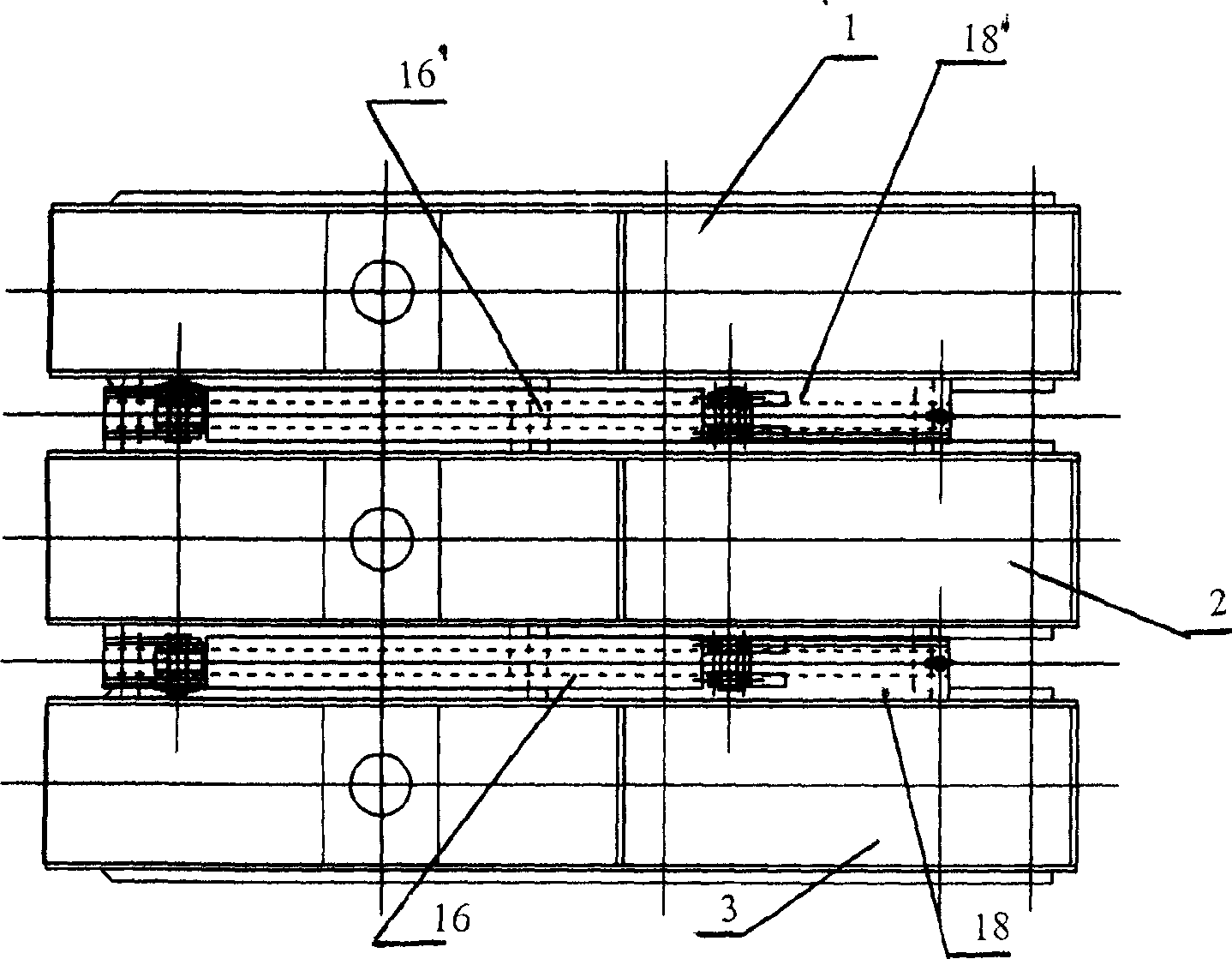

[0023] First refer to figure 1 and Fig. 2 illustrate according to the blast mining hydraulic support of the present invention, each blast mining hydraulic support includes three support sections, namely an intermediate support section 2 and two adjacent support sections 1, 3, and the three support sections are arranged in parallel. The intermediate support section 2 and the adjacent support sections 1 and 3 are basically the same in structure, the difference is that the guiding coupling mechanism and the pushing device used for the relative movement of the intermediate support section 2 and the adjacent support sections 1 and 3 are interactive structures, which are explained separately below .

[0024] With reference to Fig. 2, Fig. 5 and Fig. 8, wherein Fig. 2 is the side view of blast mining hydraulic support of the present invention, Fig. 5 and Fig. 8 are the side views of intermediate support section and adjacent support section respectively, but in Fig. 5 and Fig. 8 only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com