Export stuff

A technology of outflow port and shell, applied in the field of lead-out plug, can solve the problems of liquid leakage at the outflow port, increased sliding resistance, reduced durability of the lead-out plug, etc., and achieves the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

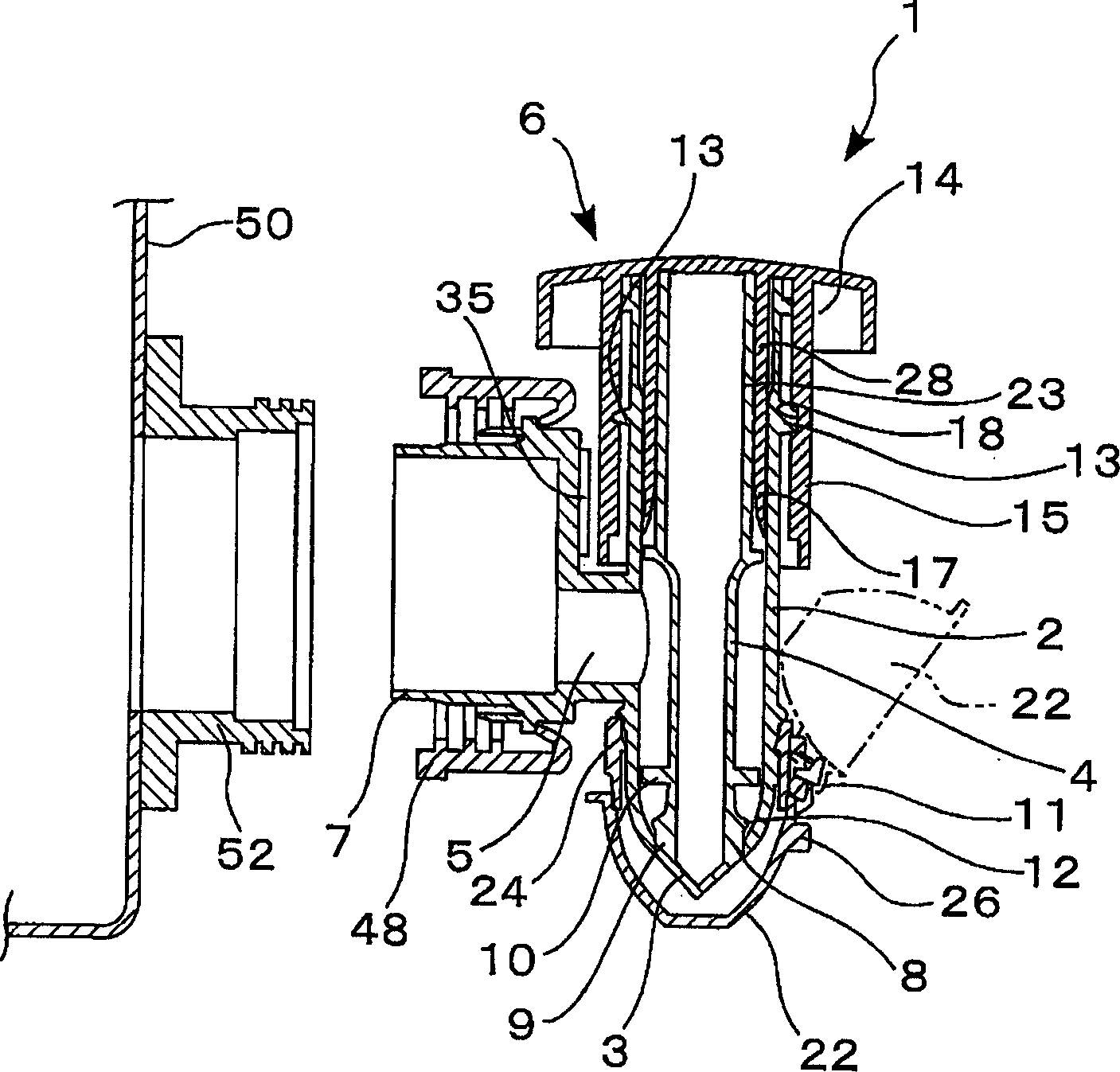

[0027] Hereinafter, one embodiment of the outlet plug of the present invention will be described with reference to the drawings.

[0028] Such as figure 1 As shown, the outlet plug 1 structurally includes: a resin housing 2; a valve body 4 provided in the housing 2; a handle 6 screwed on the upper part of the housing 2 as an operating component, and the like. The lead-out plug 1 is installed on the discharge port 52 of the container 50 through a screw cap 48.

[0029] The container 50 is a container made of resin for containing seasonings and liquors and other liquids. It may be a flexible container that is easily deformed or a rigid container that is not easily deformed. An integrated discharge port 52 is installed on the lower wall surface by welding or the like.

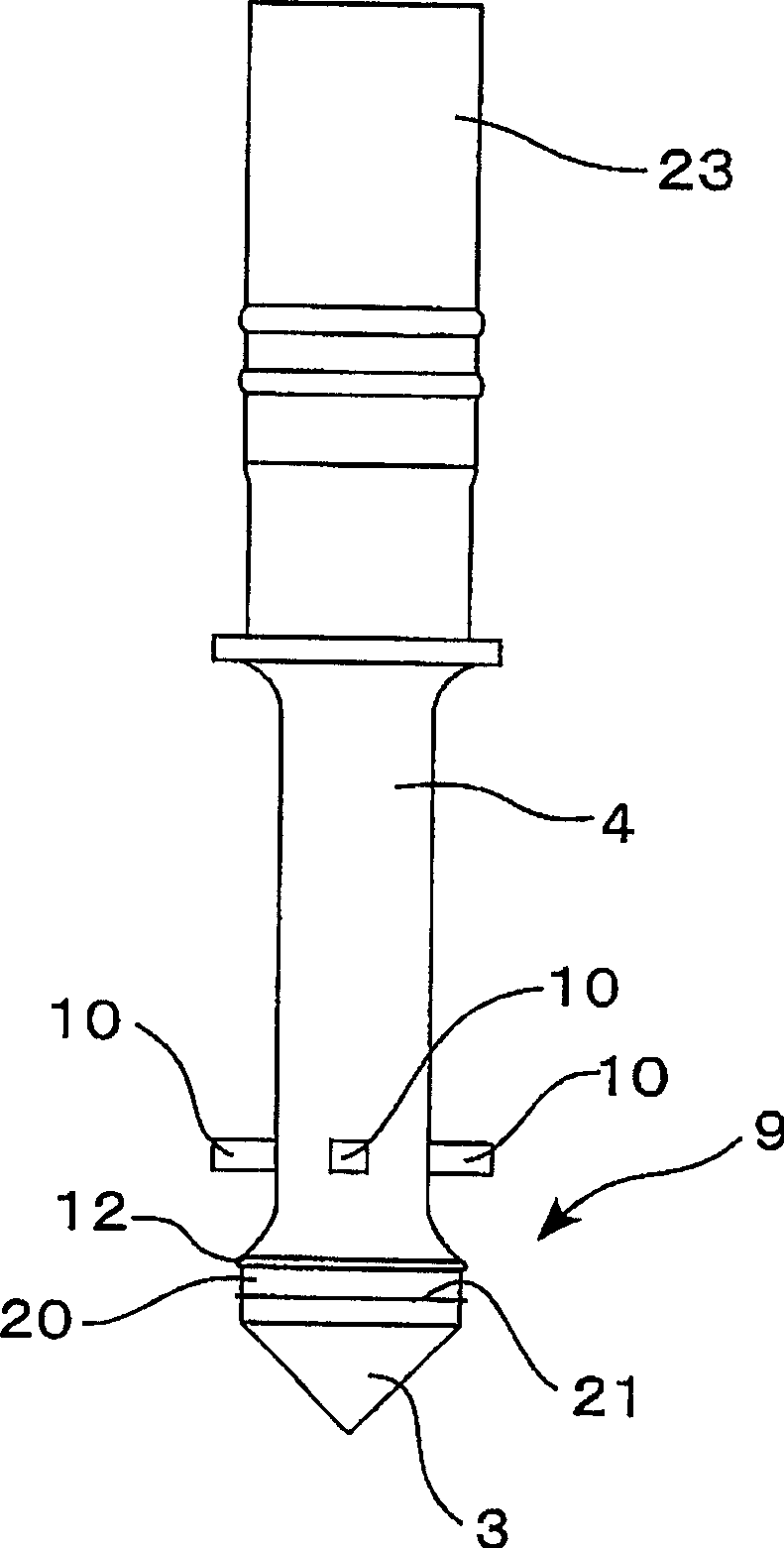

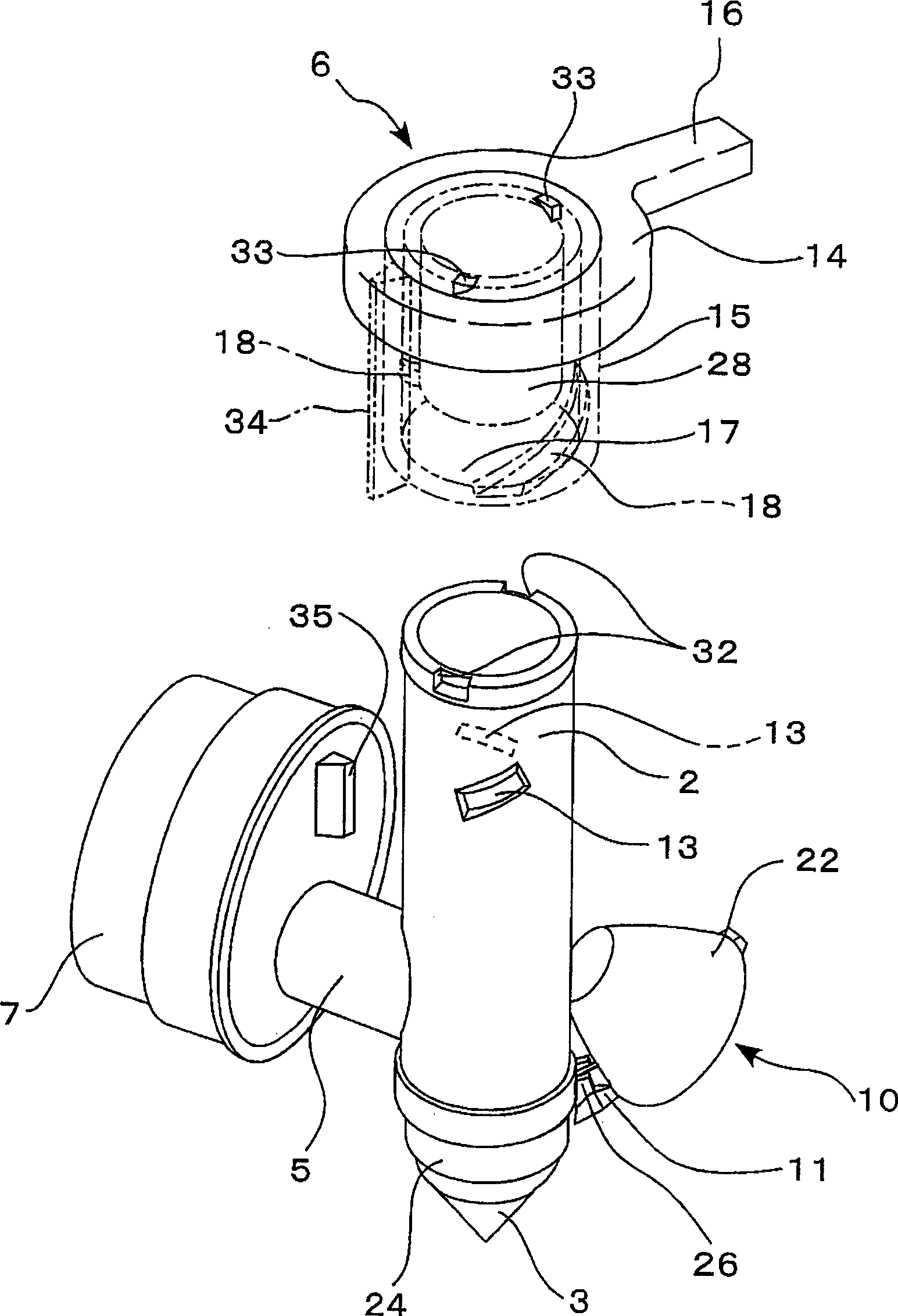

[0030] The shell 2 is a vertical cylindrical shape with an open top, such as image 3 As shown, a pair of opposite engagement pieces 13 with different widths are formed on the outer peripheral surface of the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com