Characteristic aldehyde-less cold core box resin

A cold core box and resin technology, applied in cores, casting molding equipment, casting molds, etc., can solve the problems of poor moisture resistance of sand cores, poor process performance, affecting workers' health, etc., to extend the usable time, improve Anti-hygroscopic, health-protecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

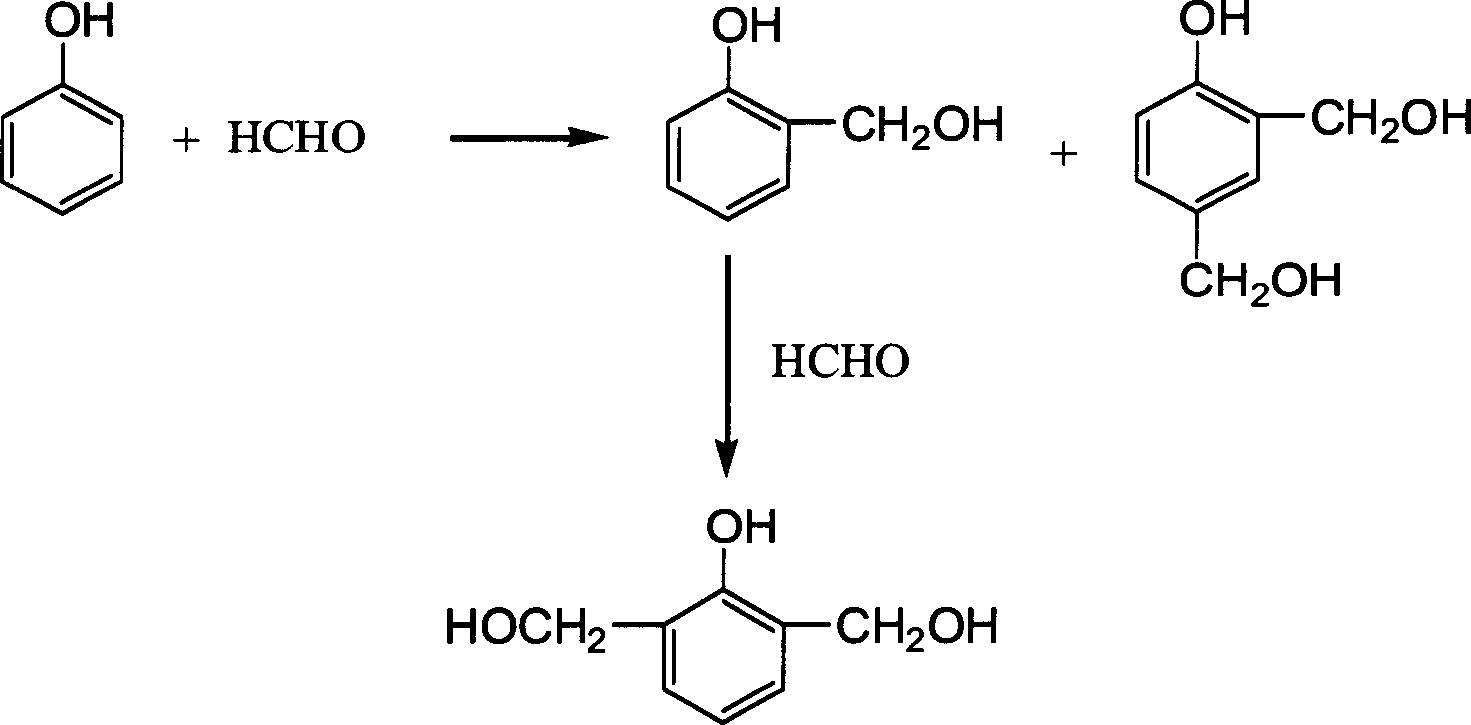

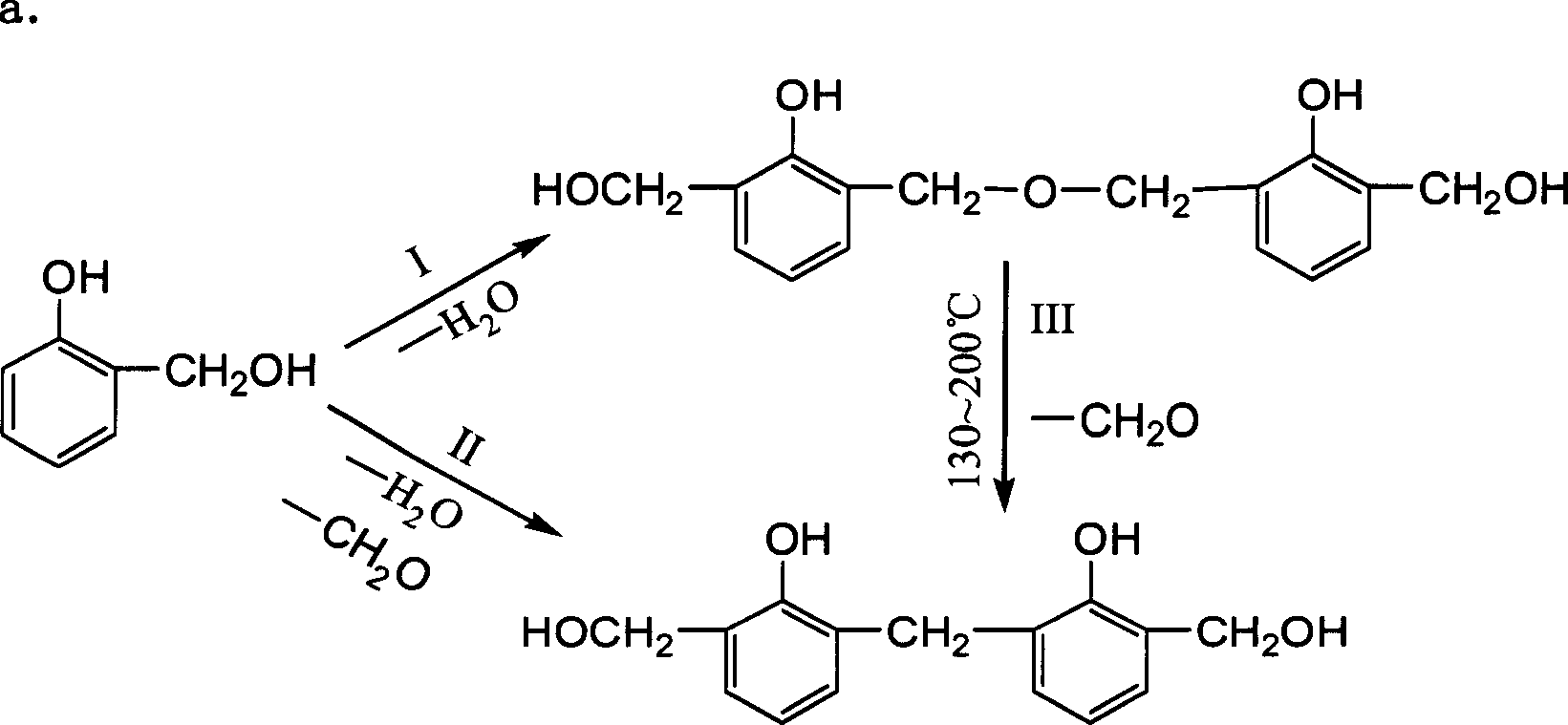

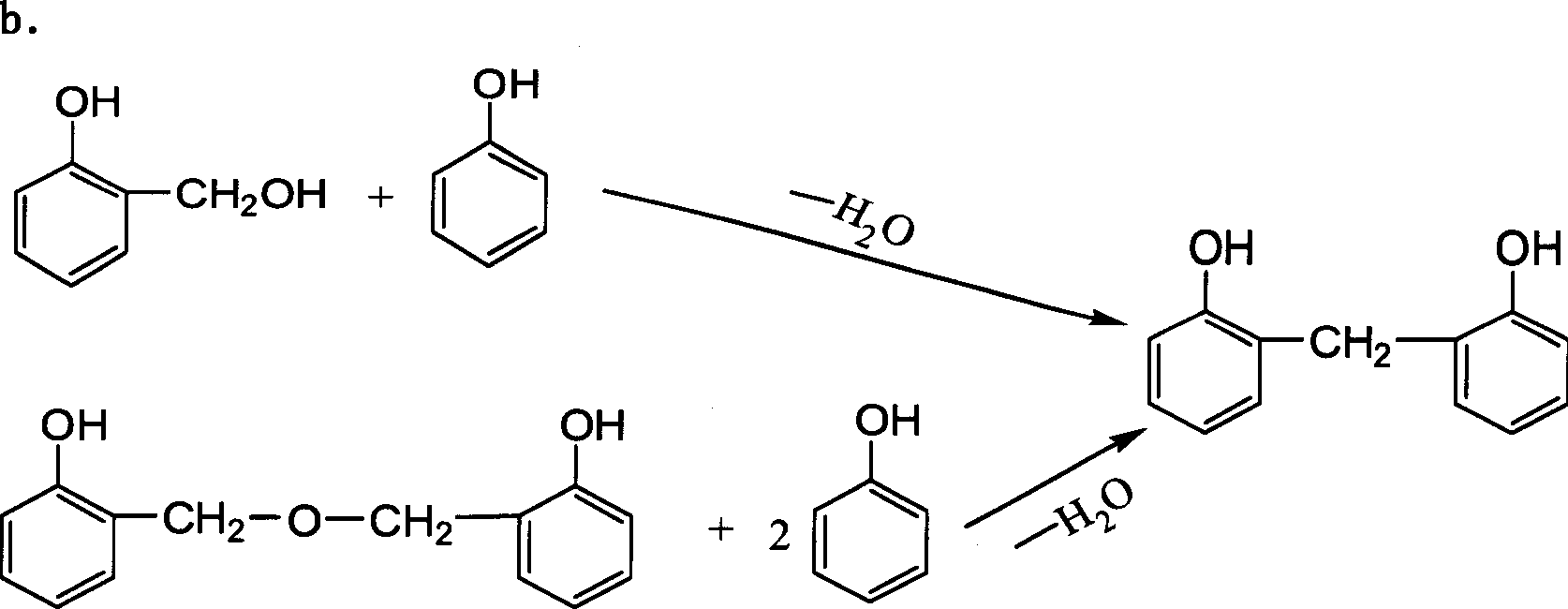

Method used

Image

Examples

Embodiment

[0024] Embodiment: a characteristic formaldehyde-free cold box resin, including two components I and II, the I component is a phenolic resin, with formaldehyde, phenol, modified animal fats, and aromatic hydrocarbon solvents as main raw materials, synthesized through chemical reactions; Component II is mainly made of polyisocyanate and modified animal fat;

[0025] The production process of component I includes the following steps:

[0026] (1) 485 kilograms of formaldehyde are dropped into reactor, start stirring, put in 1000 milliliters of 20% dilute hydrochloric acid;

[0027] (2) pump 400 kilograms of phenol into melting;

[0028] (3) Open the steam valve to raise the temperature, the heating time is 55-60 minutes, and the feed liquid is heated to 109±2°C;

[0029] (4) Incubate at 109±2°C for 40 minutes;

[0030] (5) After the heat preservation is completed, the temperature of the material is raised to 115±2°C, and the heating time is 10 minutes;

[0031] (6) Keep warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com