Three dimensional integrated micro mechanical acceleration sensor and producing method

An acceleration sensor and acceleration sensing technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of high paraxial sensitivity, signal output is prone to interference, etc., so that the production cost is not high and the final realization is easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The substantive characteristics and remarkable progress of the present invention are further illustrated below through specific examples, but the present invention is by no means limited to the examples described.

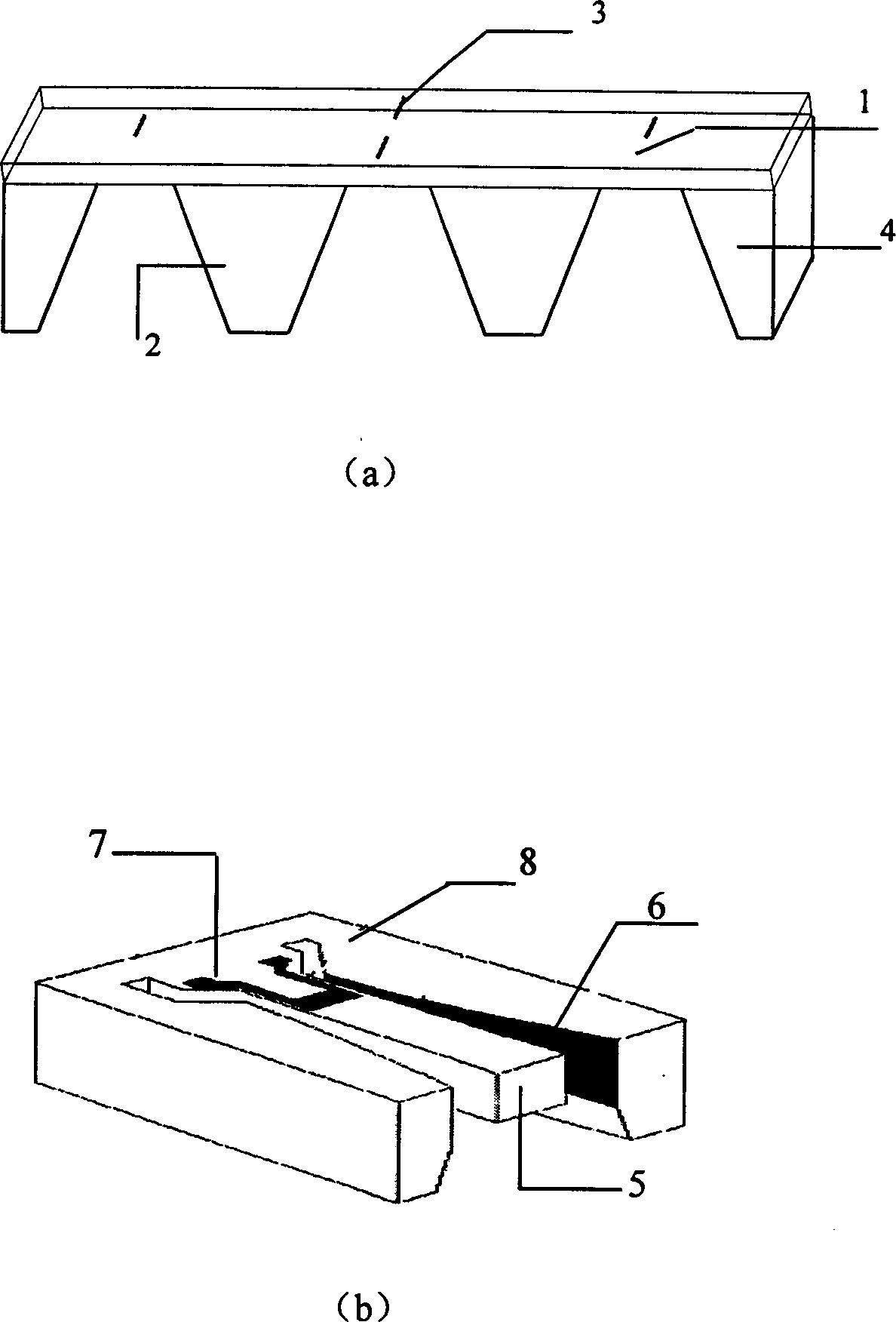

[0042] Design and manufacturing process of a three-dimensional integrated high-shock acceleration sensor with a measuring range of 50,000 g:

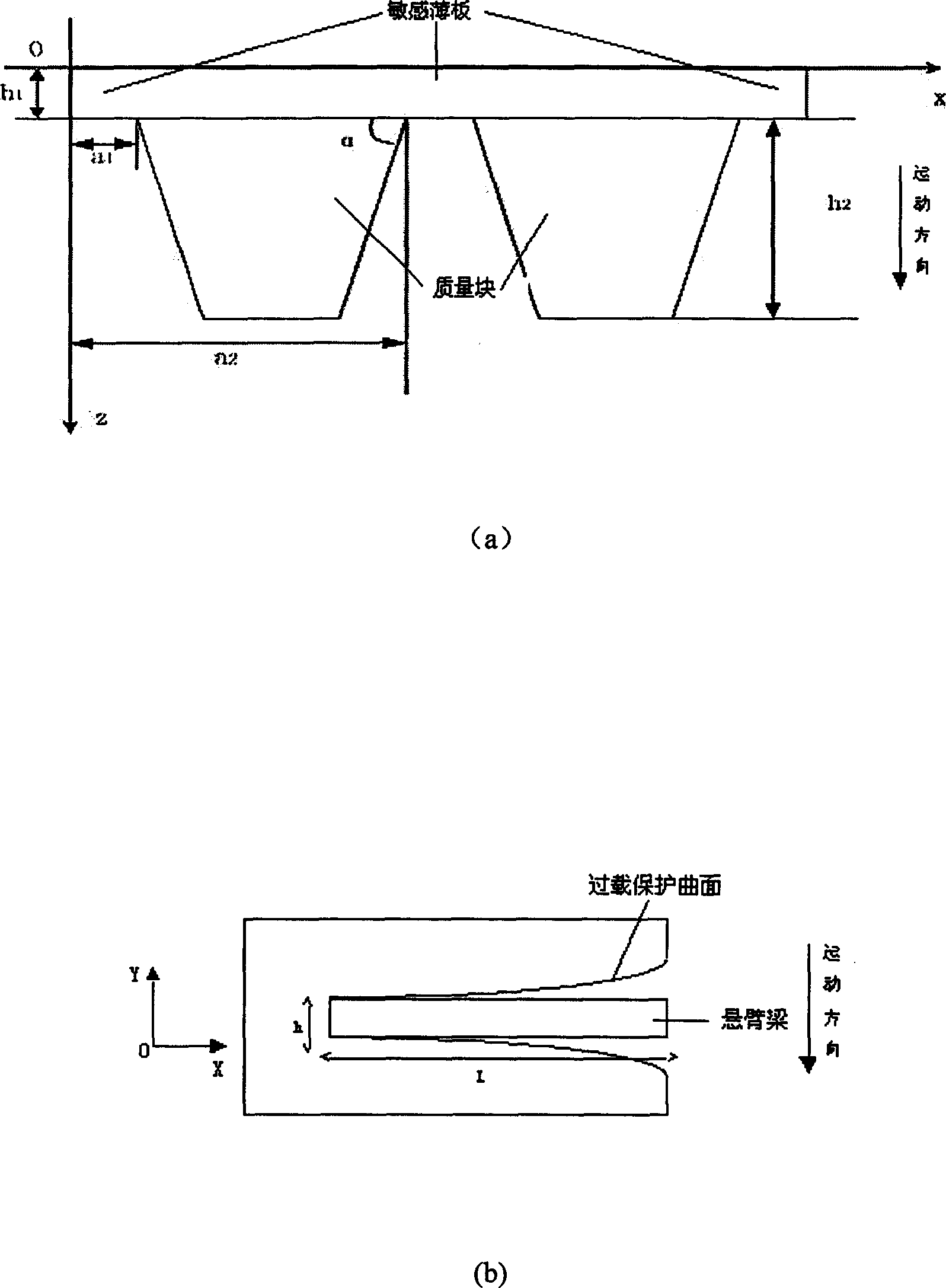

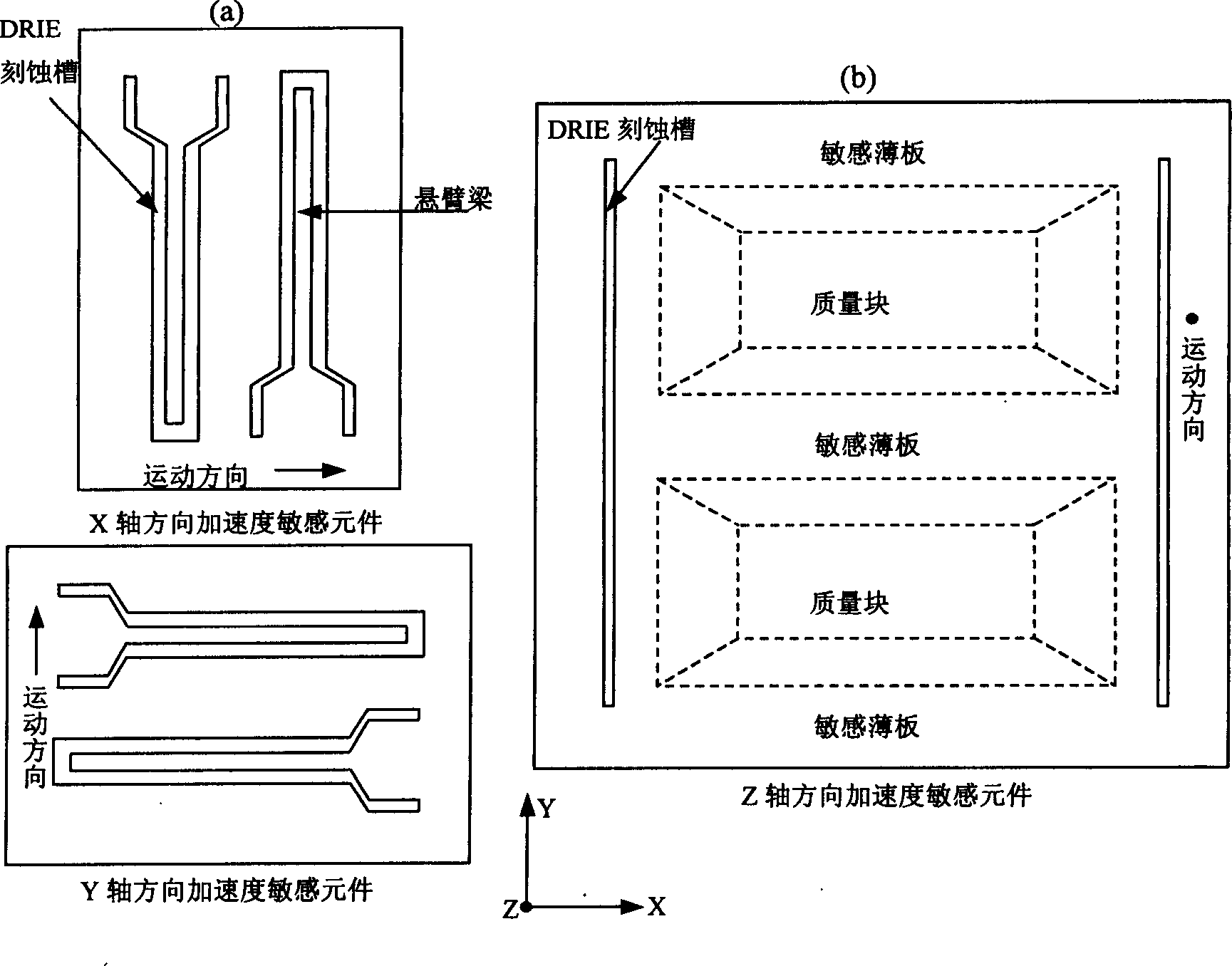

[0043] 1. The structural size of the acceleration sensing element in the X and Y axis directions: the length of the cantilever beam is 515 μm, the thickness is 16 μm, and the width is 50 μm;

[0044] 2. The structural size of the acceleration sensing element on the Z axis: the thickness of the thin plate is 50 μm, the length is 50 μm, the thickness of the mass block is 370 μm, the total length of the mass block and the thin plate is 670 μm, and the width of the entire structure is 1400 μm.

[0045] The dimensions of the entire three-dimensional integrated high-shock acceleration sensor are: length 4100 μm, width 3500 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com