Exposure apparatus

An exposure device and mask technology, which is applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of large errors, time-consuming, difficult to apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the exposure method of the exposure apparatus according to the present invention will be described with reference to the drawings.

[0024] The present invention is an exposure apparatus that calibrates a substrate having a plurality of calibration marks for positioning, and a mask having mask marks for aligning positions with the calibration marks and a mask provided with a predetermined pattern. Exposure is carried out in a state where it fits on the substrate.

[0025] First, the exposure device will be described.

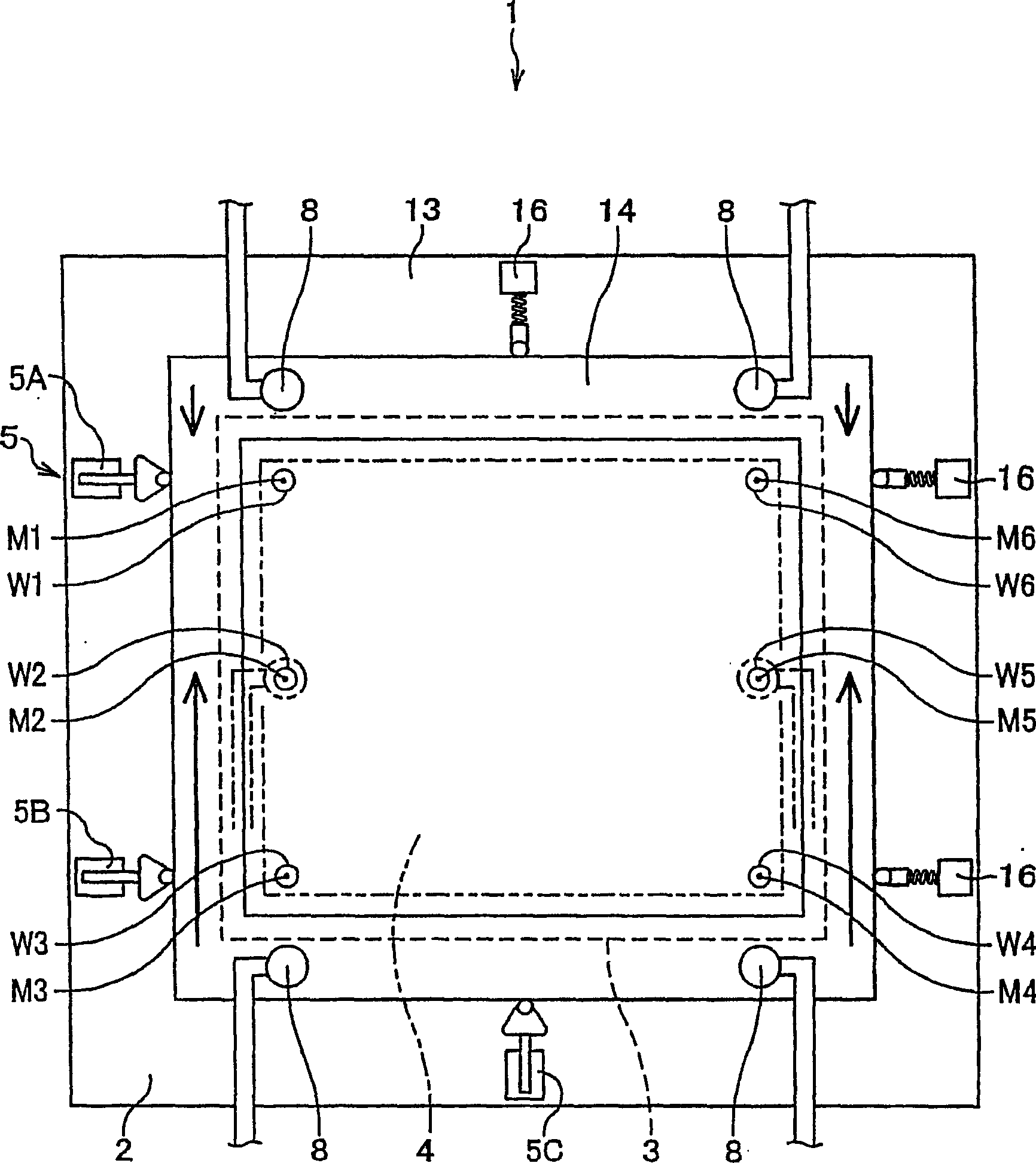

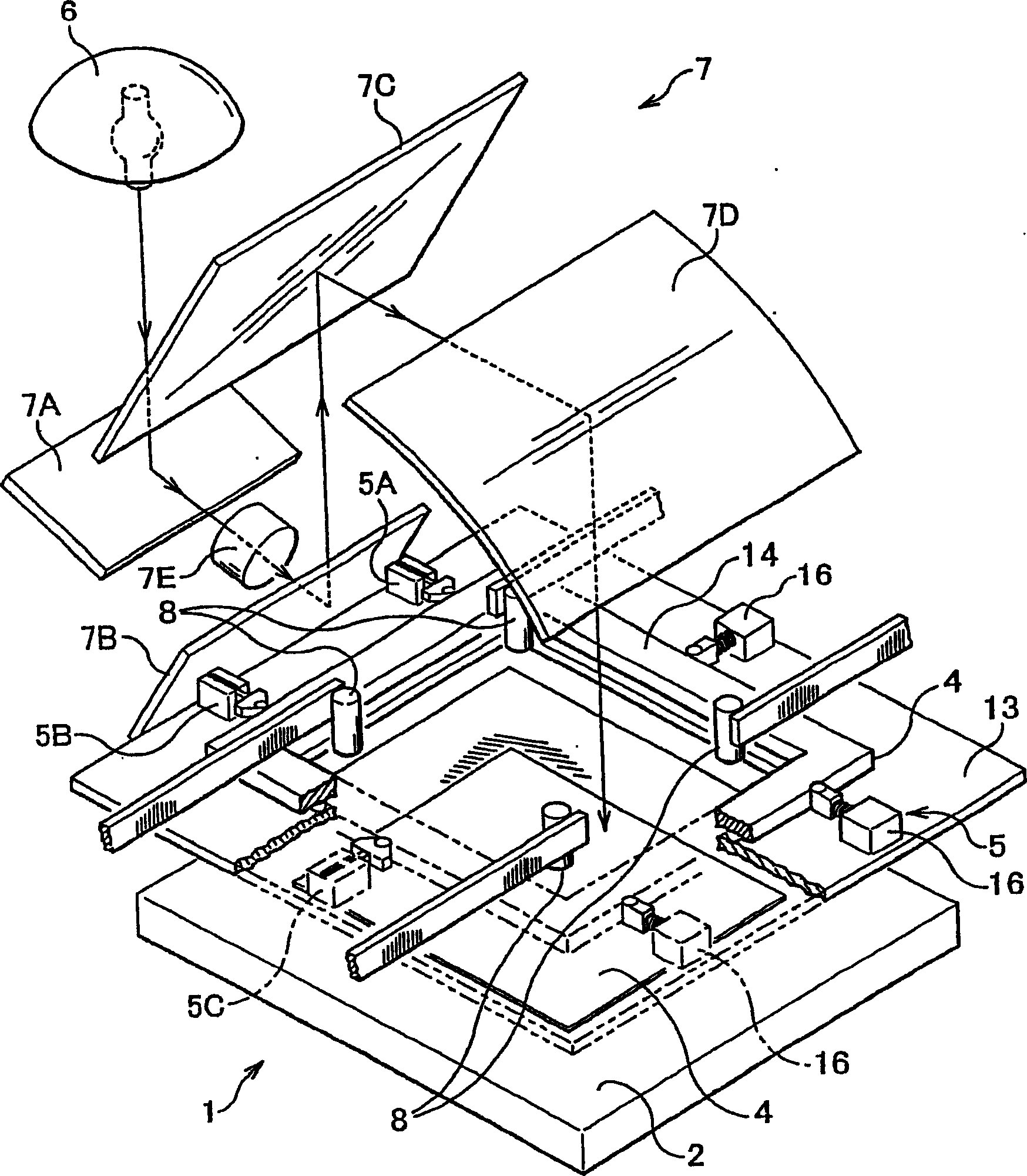

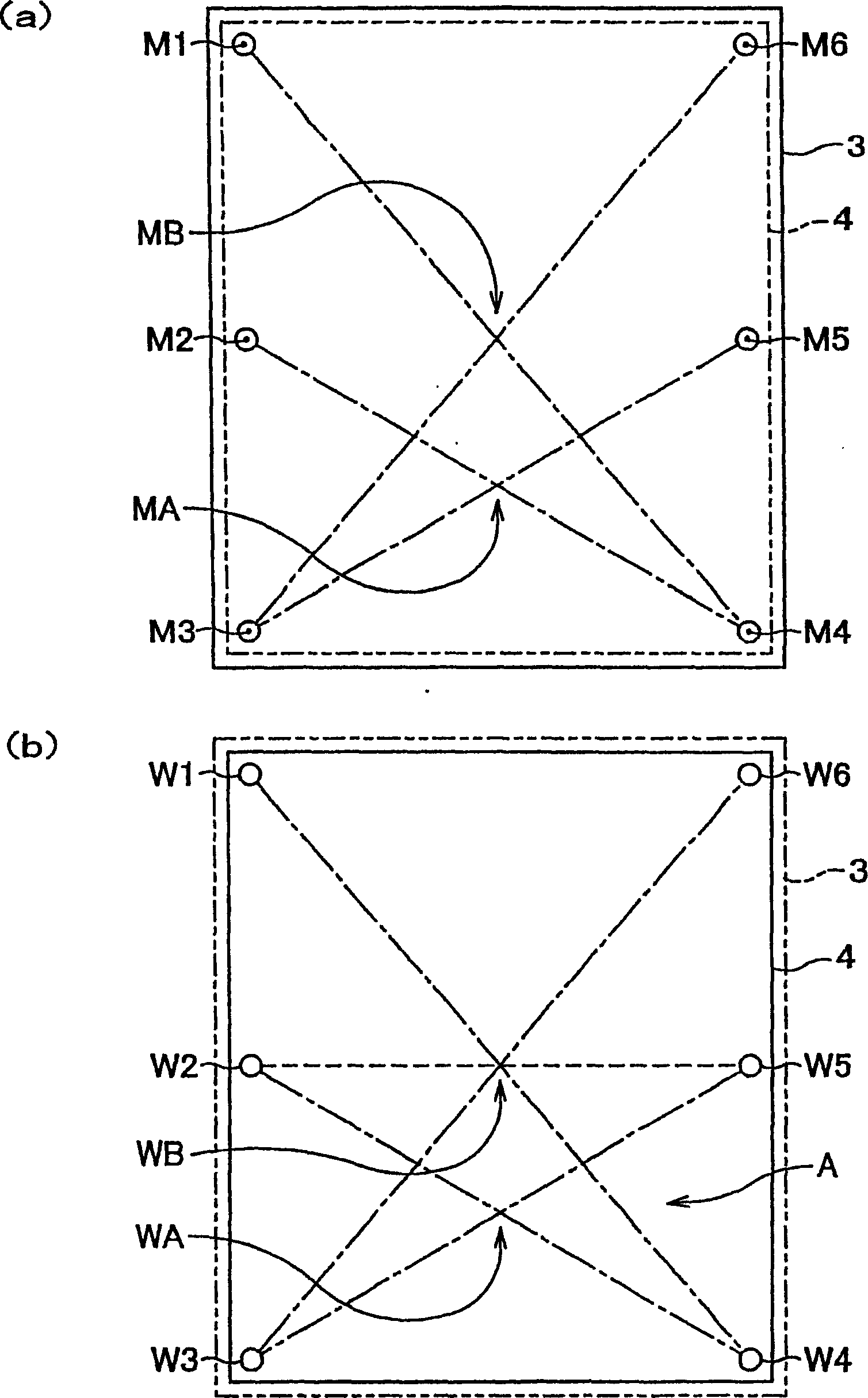

[0026] In the attached drawings, figure 1 It is a plan view showing main parts of the exposure apparatus. figure 2 It is a three-dimensional schematic diagram of the whole exposure device. image 3 (a) is a schematic diagram showing the arrangement of mask marks on the mask. image 3 (b) is a schematic diagram showing the arrangement of alignment marks on the substrate. Figure 4 A schematic side view of the exposure devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com