Dust-proofing road-sweeping lorry

A technology for sweepers and car bodies, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of high power consumption, complex structure of sweepers, and many running parts, etc., and achieves the effect of improving work performance and eliminating dust removal equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

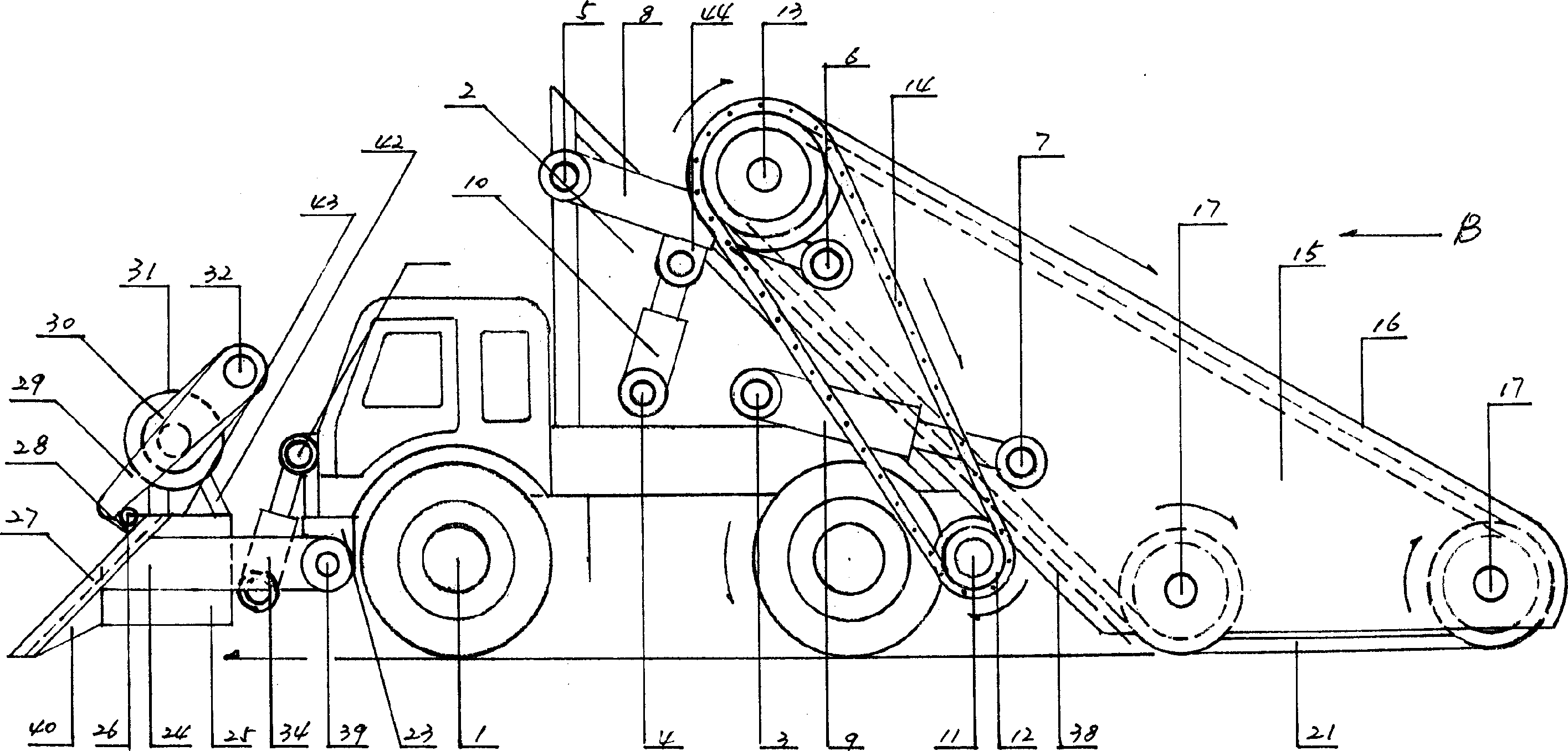

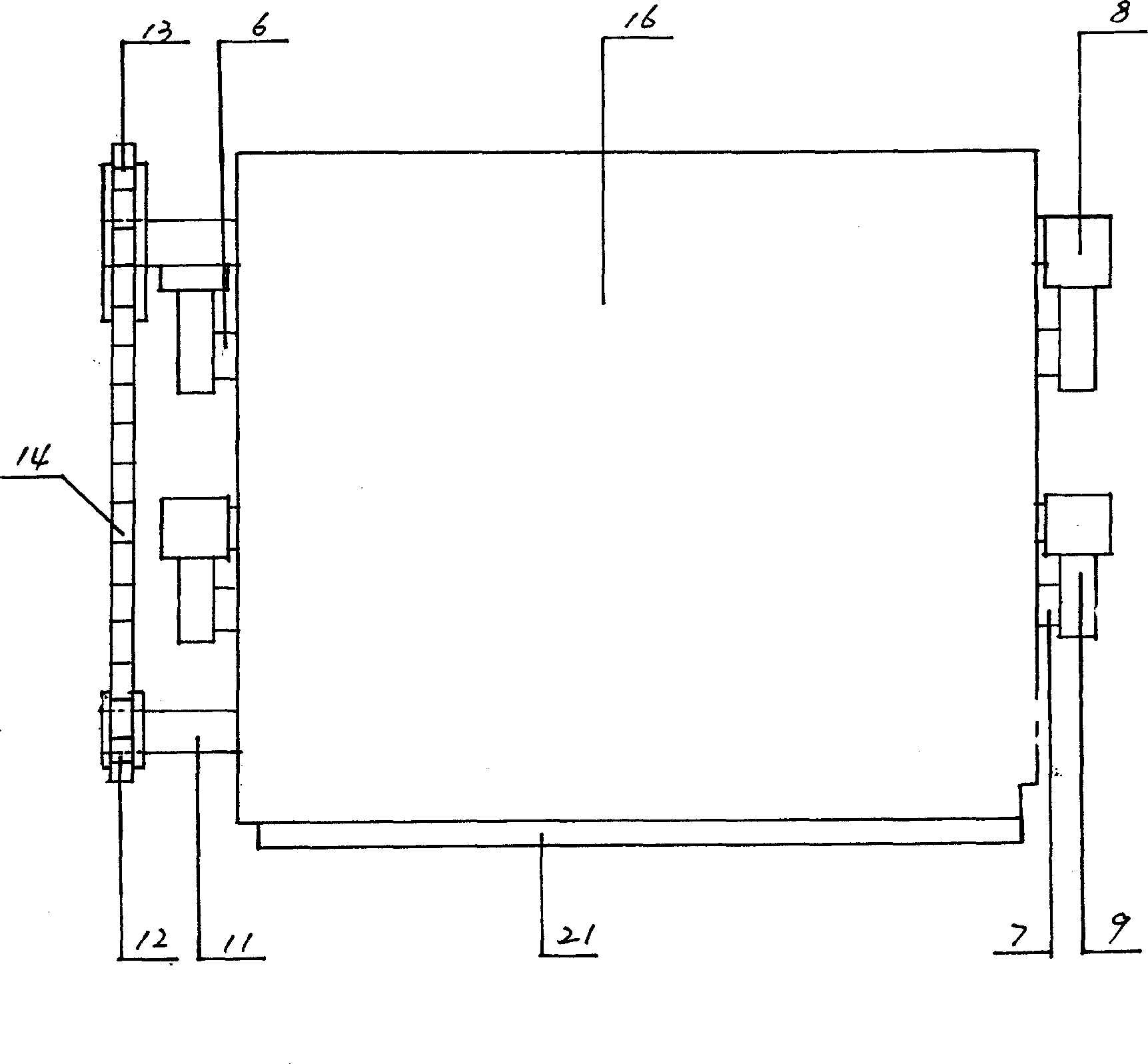

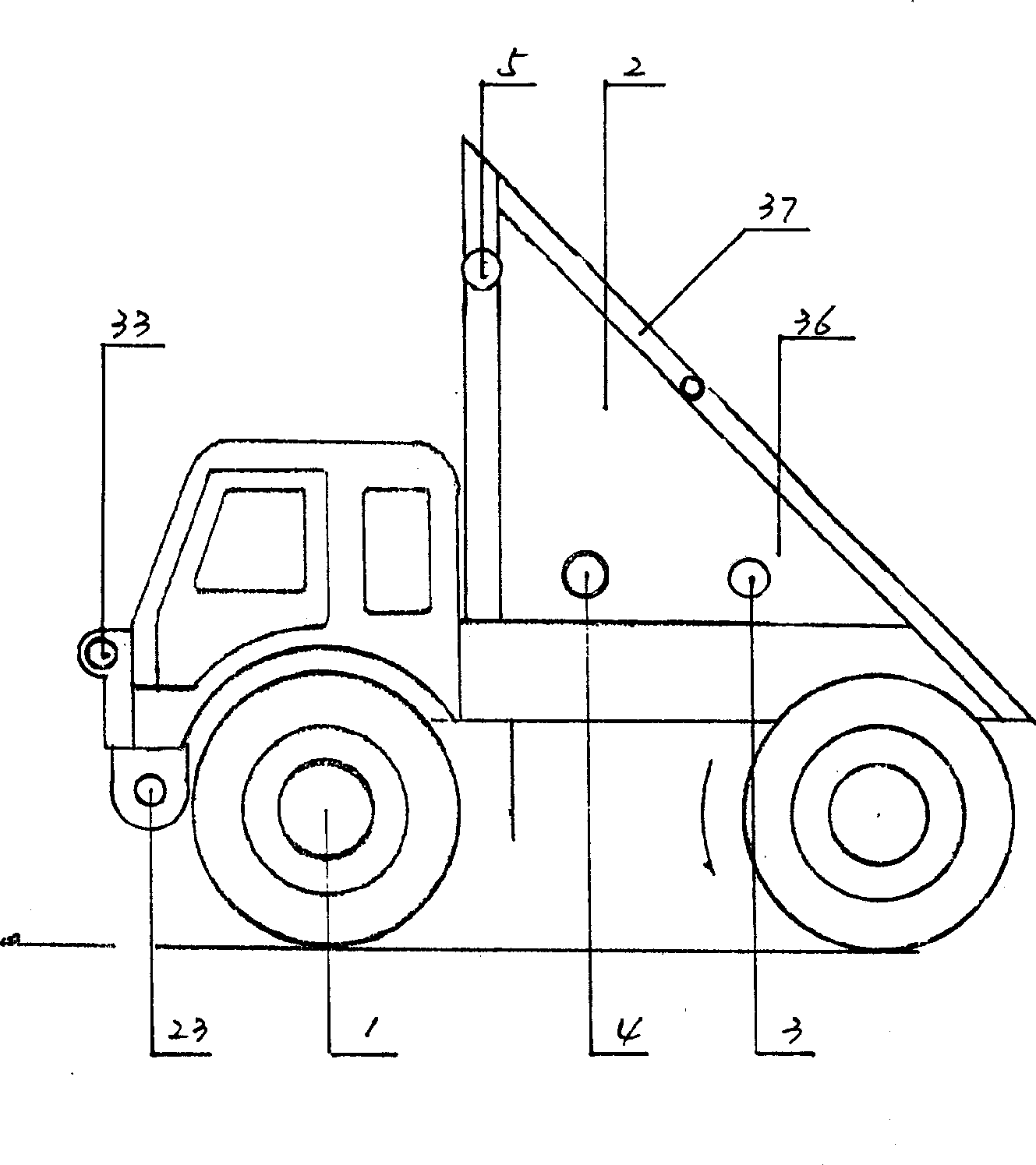

[0022] Below in conjunction with embodiment, make further detailed description. like figure 1 , 2 , 3, 4, shown, on the front end girder of car body 1, two U-shaped connecting clips 23 are installed, and U-shaped clip 33 is installed in the middle part of its girder, and the tipping car box is refitted into a triangular shape and reinforced. The both sides of good carriage 2 are installed carriage shaft head 3,4,5 respectively, completes car body refitting.

[0023] Large waste removal system such as figure 1 , 12 As shown, it is installed at the forefront of the car body, mainly consisting of a shovel 27, a garbage bucket 25 and a manipulator device. The distance from the shovel 27 to the road is controlled by the lifting of the oil cylinder 34. Cover 39 is connected as a whole with pivot pin and connecting card 23. The shovel plate 27 is obliquely placed in front of the dustbin 25 and is fixedly connected with the front end of the dustbin 25 and the crossbeam 24, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com