Button-sewing machine

A button sewing machine and button technology, which is applied in the field of button sewing machines, can solve the problems of not being able to effectively rely on the thread, thread winding and cutting, etc., and achieve the effect of reducing the extension and increasing the sewing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] (Overall configuration of the embodiment)

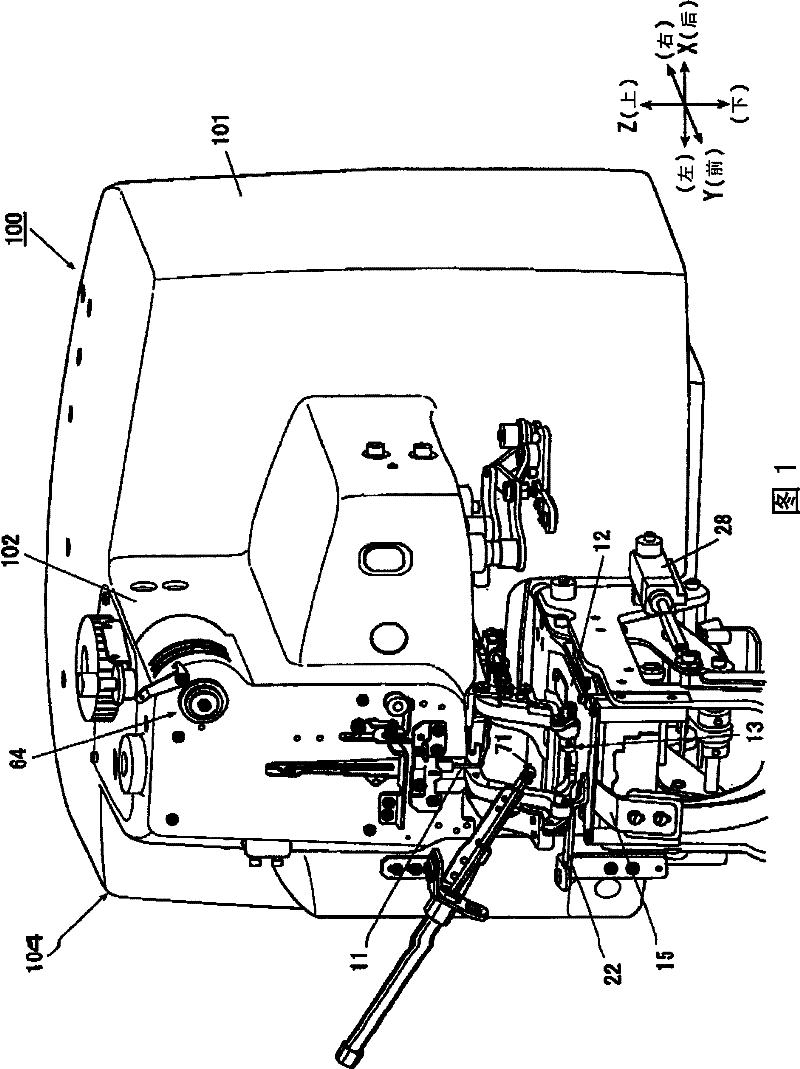

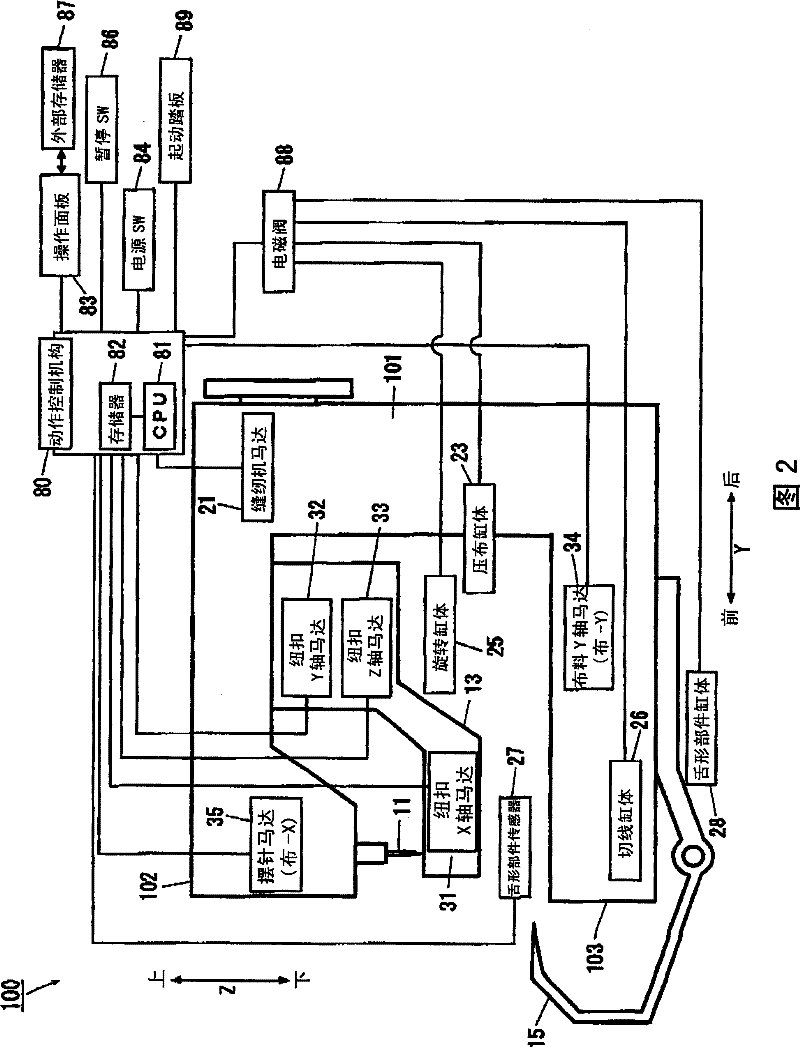

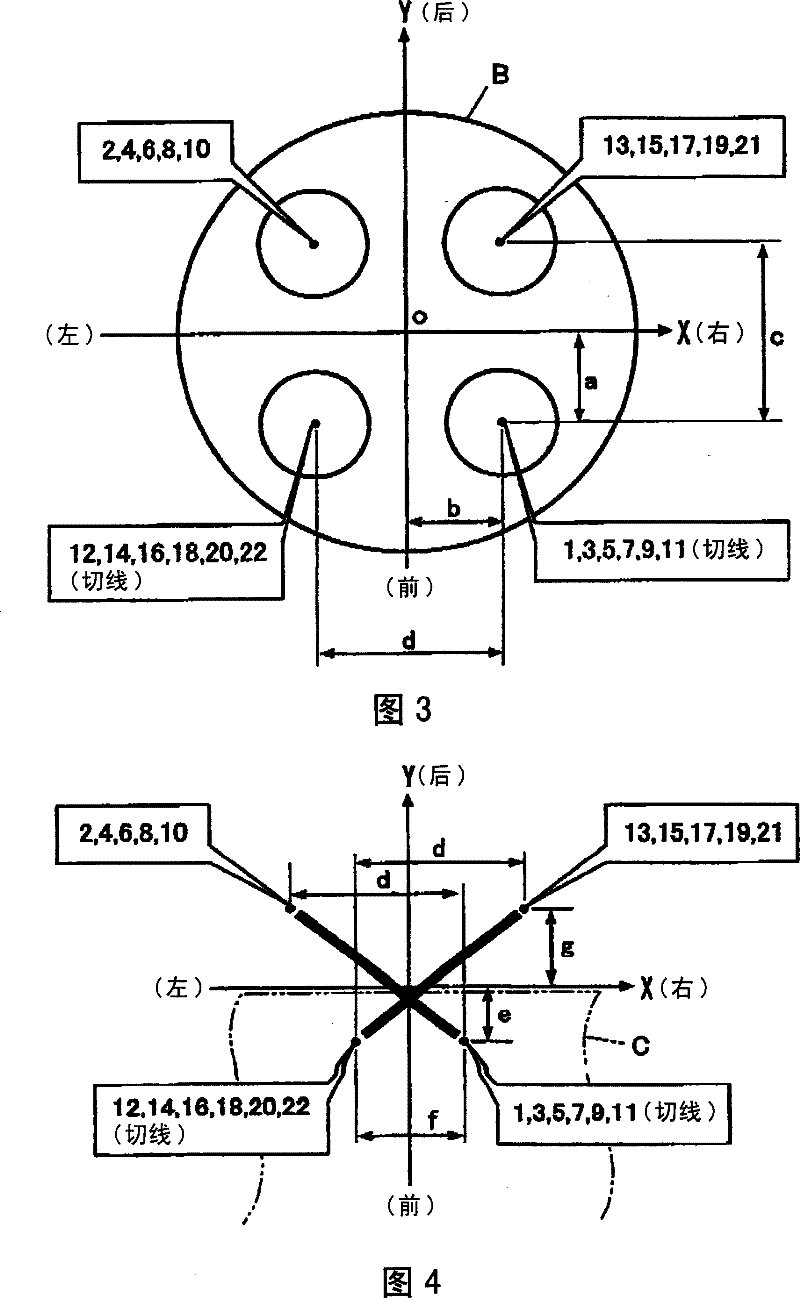

[0056] Below, based on Figure 1 to Figure 13 , the button sewing machine 100 according to the embodiment of the present invention will be described.

[0057] figure 1 is a perspective view showing the main configuration of the button sewing machine 100, figure 2 It is a block diagram showing the main configuration of the button sewing machine 100 .

[0058] The button sewing machine 100 is a machine that sews a button B onto a cloth C using a sewing thread T through the cooperative action of the vertically moving needle 11 , the looper 41 , and the thread resting member 42 .

[0059] Button sewing machine 100, its whole is made up of: the sewing machine base plate 103 that is positioned at its lower part, the sewing machine vertical body portion 101 that is erected upwards from one end portion of the rear of the sewing machine base plate 103, and the sewing machine vertical body portion 101 along the top of the sewing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com