Joint torque sensor capable eliminating harmonic wave effect by itself

A joint torque and harmonic elimination technology, applied in the field of joint torque sensors, can solve the problem that the joint torque sensor cannot eliminate the influence of harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

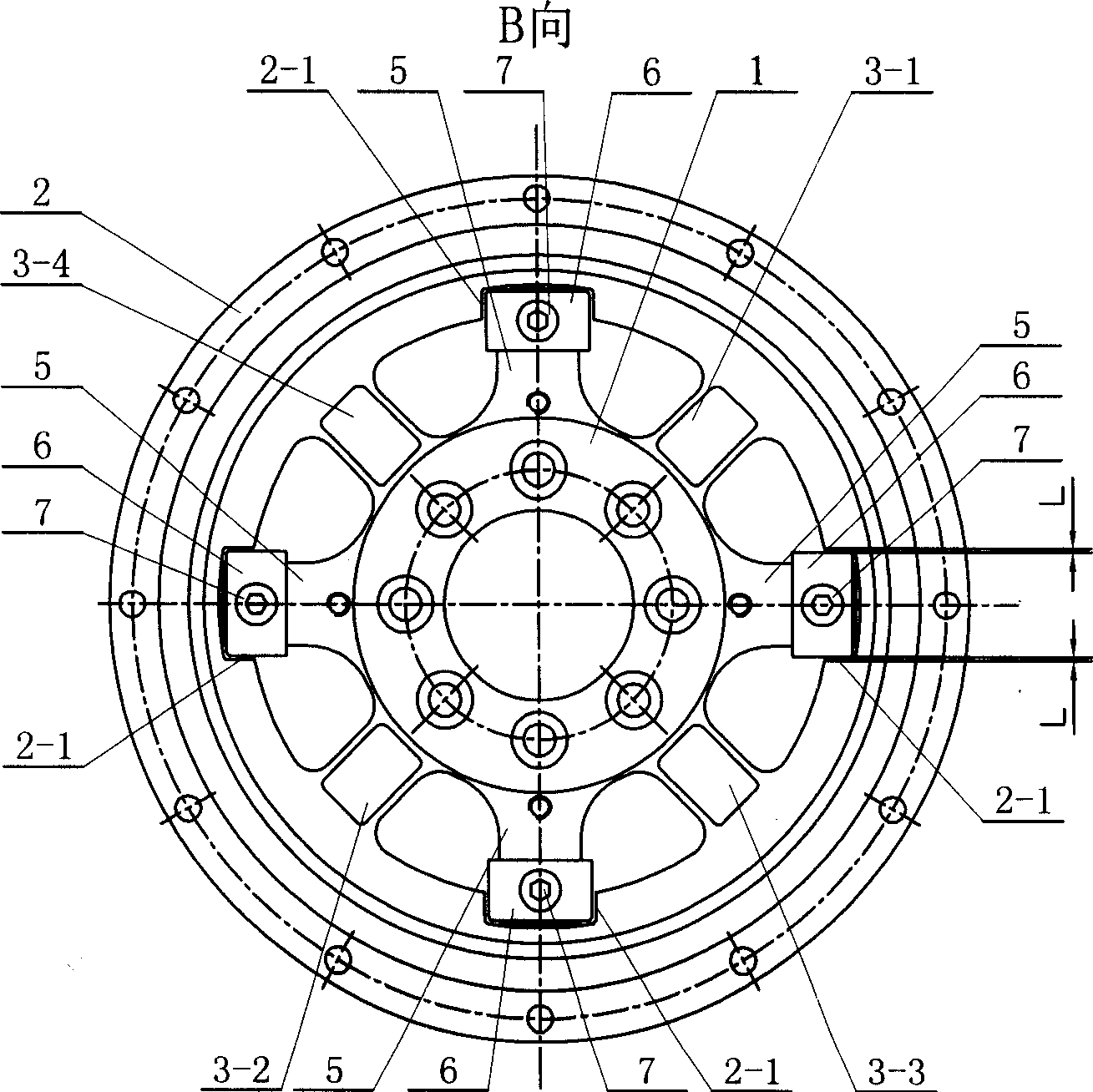

[0005] Specific implementation mode one: (see Figure 1-Figure 4 ) This embodiment includes a torque input disc 1, a torque output disc 2, a sensor strain beam 3 and a strain gauge 4, and there are four sensor strain beams 3, which are No. 1 strain beam 3-1, No. 2 strain beam 3-2, Both ends of No. 3 strain beam 3-3 and No. 4 strain beam 3-4, No. 1 strain beam 3-1, No. 2 strain beam 3-2, No. 3 strain beam 3-3 and No. 4 strain beam 3-4 Respectively connected with the outer edge of the torque input disc 1 and the inner edge of the torque output disc 2 as a whole and uniformly distributed along the circumference of the torque input disc 1; the strain gauges 4 are eight, No. 1 strain beam 3-1, No. 2 strain gages No. strain beam 3-2, No. 3 strain beam 3-3 and No. 4 strain beam 3-4 are respectively fixed with two strain gauges 4, and No. 1 strain beam 3-1 and No. 2 strain beam 3-2 are fixed with four strain gauges. The four strain gauges 4 on the No. 3 strain beam 3-3 and the No. 4 ...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see Figure 1-Figure 3 ) The difference between this embodiment and the specific embodiment one is that the eight strain beams fixed on No. 1 strain beam 3-1, No. 2 strain beam 3-2, No. 3 strain beam 3-3 and No. 4 strain beam The strain gauges 4 are located on the same plane. Other compositions and connections are the same as in the first embodiment. The eight strain gauges 4 described in this embodiment are located on the same plane, and the strain gauges adopt a full-plane pasting method, which is convenient for pasting.

specific Embodiment approach 3

[0007] Specific implementation mode three: (see Figure 1-Figure 3 ) The difference between this embodiment and the specific embodiment 1 or 2 is that it increases the sensor protection beam 5, and the sensor protection beam 5 is fixedly connected with the outer edge of the moment input disc 1 between two adjacent sensor strain beams 3, The inner edge of the torque output disk 2 is provided with a protective beam installation groove 2-1 corresponding to the sensor protection beam 5, and the end of the sensor protection beam 5 is placed in the protective beam installation groove 2-1 on the torque output disk 2. And a gap L is formed between the two side walls of the protection beam installation groove 2-1. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2. During the working process of the joint, excessive load torque may occur, which will damage the joint torque sensor and make it unable to work normally. The overload protection structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com