Mixed working medium deep-freezing adsorption refrigerating device

A deep freezing and adsorption refrigeration technology, applied in refrigerators, refrigeration and liquefaction, adsorption machines, etc., can solve the problems of complex structure of cascade adsorption refrigeration system, limited popularization and application, high manufacturing cost, and achieve simplified cascade adsorption refrigeration system. Adsorption refrigeration system, broad application prospects, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

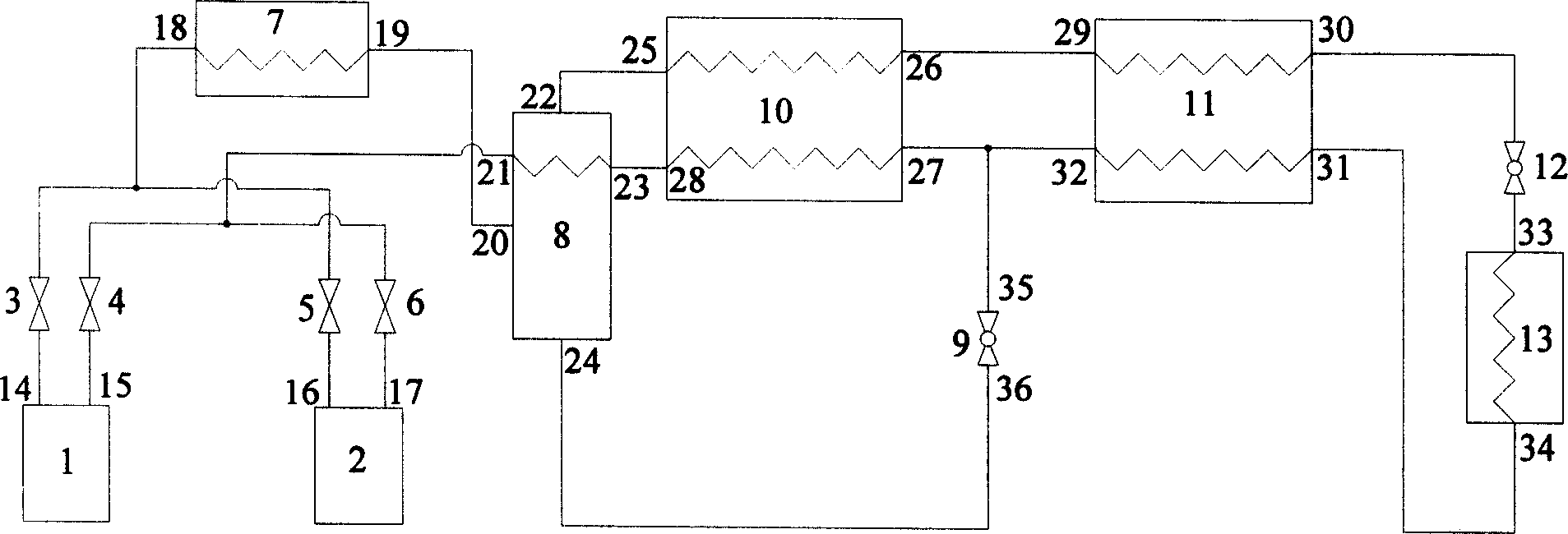

[0011] The present invention has the first adsorption-desorber 1, the second adsorption-desorber 2, the condenser 7, the component separation module 8, the second throttling device 9, the second regenerator 10, and the first regenerator connected in sequence. device 11, first throttling device 12 and evaporator 13, solid adsorbent is housed in the first adsorption-desorber 1 and the second adsorption-desorber 2.

[0012] The end of the pipeline connected to the first port 18 of the condenser 7 is divided into two paths: the one branched from the end of the pipeline connected to the first port 18 of the condenser 7 passes through the first valve 3 and the first of the first adsorption-desorber 1. Port 14 links to each other, and the other way that the pipeline end that is connected with the first port 18 of condenser 7 is connected with the first port 16 of the second adsorption-desorber 2 through the third valve 5, the second port 19 of condenser 7 Be connected with the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com