Soot blowing explosion wave method

An explosion wave and oxygen technology, applied in the field of explosion wave soot blowing, can solve the problems of low volume energy density of premixed gas, low explosion pressure, weak explosion wave, etc., and achieve good soot blowing effect, low cost and fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

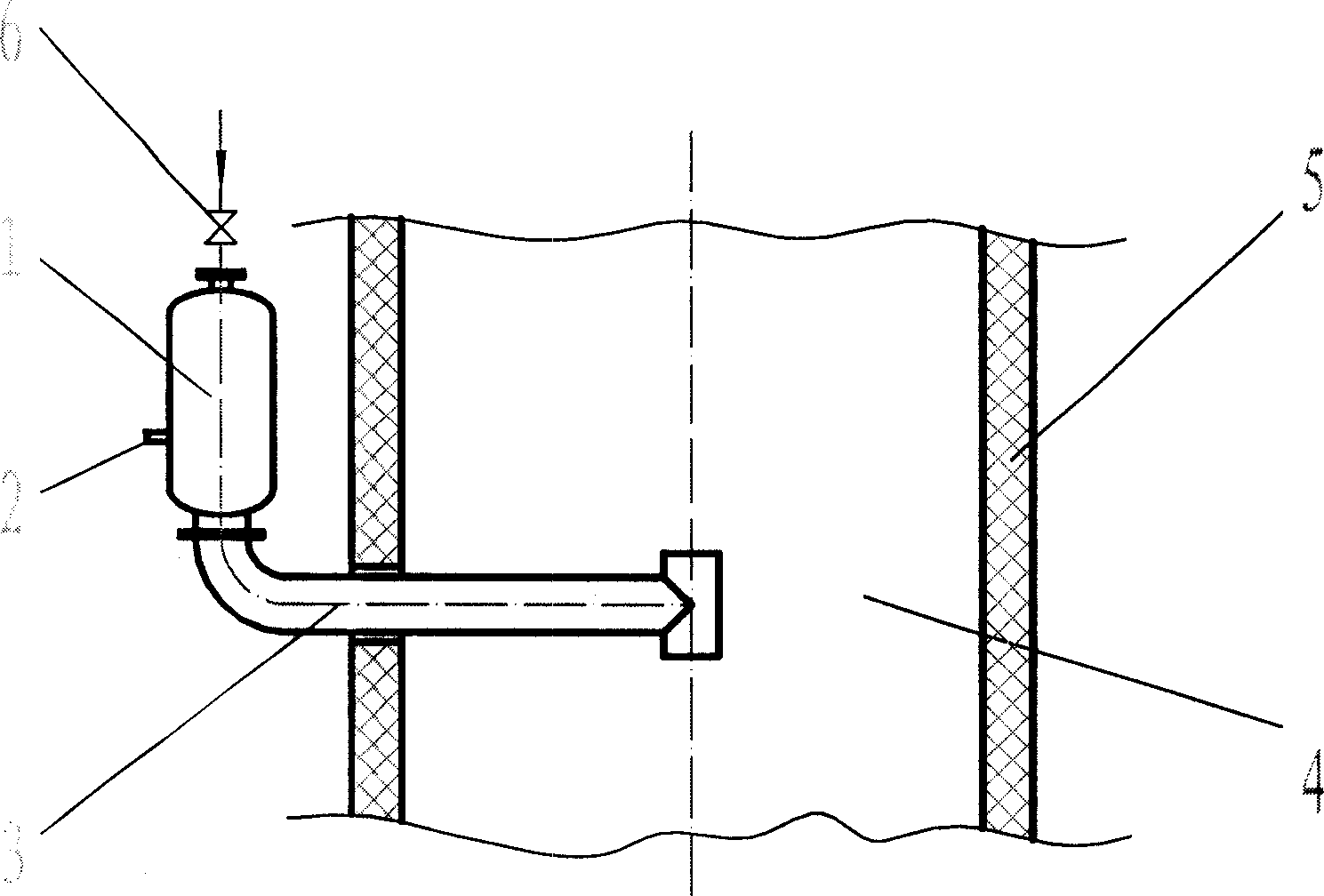

[0019] This embodiment is a method of soot-blowing the vertical flue of a coal-fired forging heating furnace using explosion waves, as shown in the attached figure 1 As shown, at first the explosion tank 1 is installed outside the furnace wall 5 of the flue 4 and the explosion tank 1 is communicated with the flue 4 by the nozzle 3 passing through the furnace wall 5, then the electromagnetic valve 6 is opened, and the explosion tank 1 is opened. Fill the premixed gas fully mixed with liquefied petroleum gas and industrial oxygen until it is full. The ratio of liquefied petroleum gas and oxygen is chemically equivalent, and then close the solenoid valve 6. After 0.1 seconds, it will be ignited by the spark plug 2. The premixed gas in the explosion tank 1 The gas will burn and explode, producing a strong explosion wave, and lead it into the flue 4 through the nozzle 3, and act on the soot on the wall surface of the flue to make it fall off.

Embodiment 2

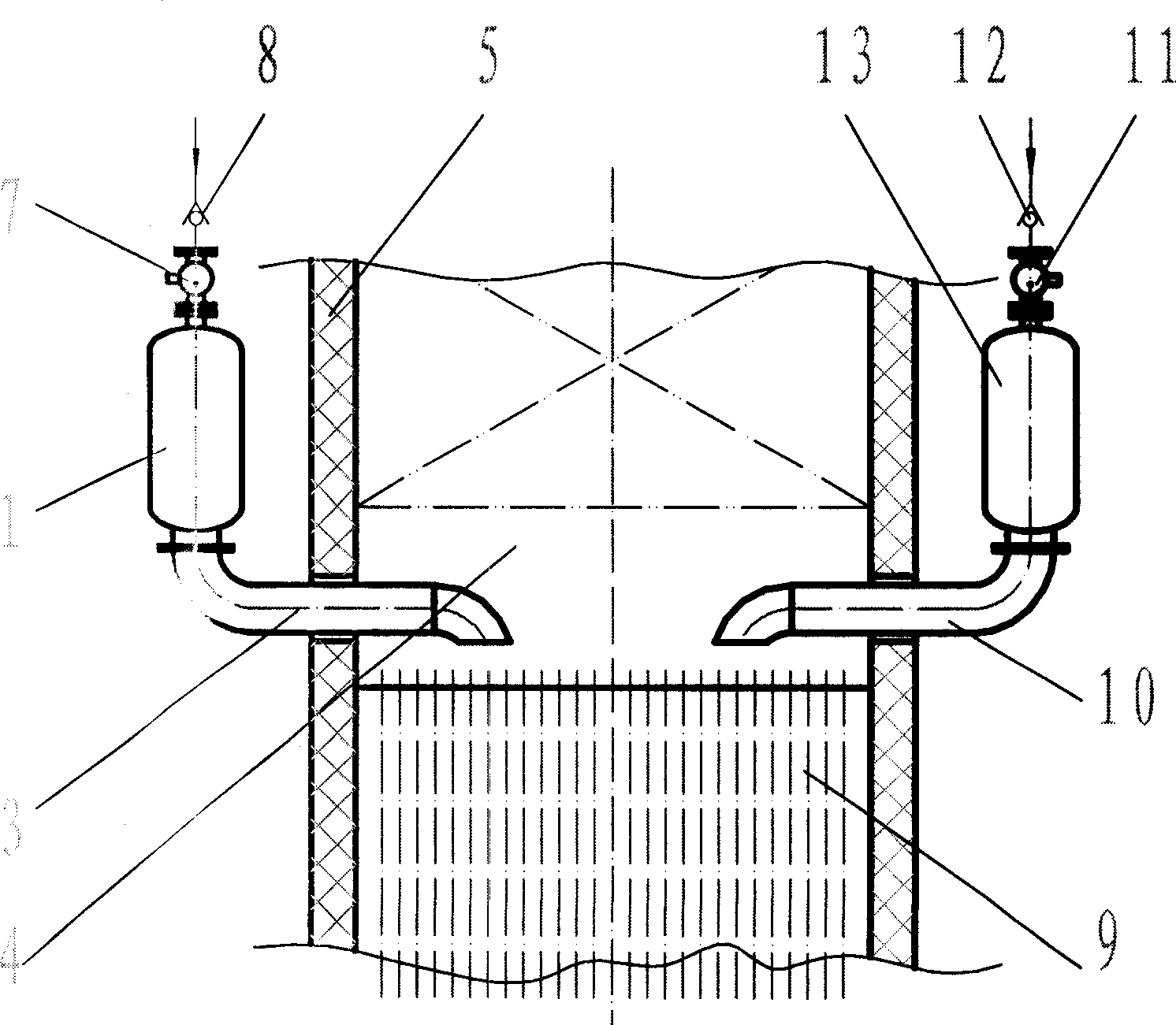

[0021] This embodiment is a method of soot-blowing the tubular air preheater in the tail flue of the boiler by using the explosion wave, as shown in the attached figure 2 As shown, at first an explosion tank 1,13 is respectively installed outside the furnace wall 5 on both sides, and the explosion tank 1,13 is communicated with the flue 4 by two spray pipes 3,10 passing through the furnace wall 5 respectively, Then in explosion tank 1,13, charge into the premixed gas after acetylene and oxygen fully mix to be full of, the proportioning of acetylene and air is 0.8 times of stoichiometric ratio, then by ignition tank 7,11 ignition, explosion tank 1 , the premixed gas in 13 will burn and explode, produce a strong explosion wave, and lead into the flue 4 through the nozzles 3 and 10, and act on the dust accumulation on the inner wall of the tube of the air preheater 9, so that the dust accumulation fall off. Since the inlet pipelines of the explosion pots 1,13 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com