Three-dimensional woven hollow layer-connecting fabric

A three-dimensional machine and fabric technology, applied in fabrics, multi-strand fabrics, textiles, etc., can solve the problems of insignificant skeleton characteristics of layered fabrics, insignificant vertical support of velvet warp, and influence of velvet warp consolidation fastness, etc., to achieve Excellent physical and mechanical properties, suitable for large-scale weaving, and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

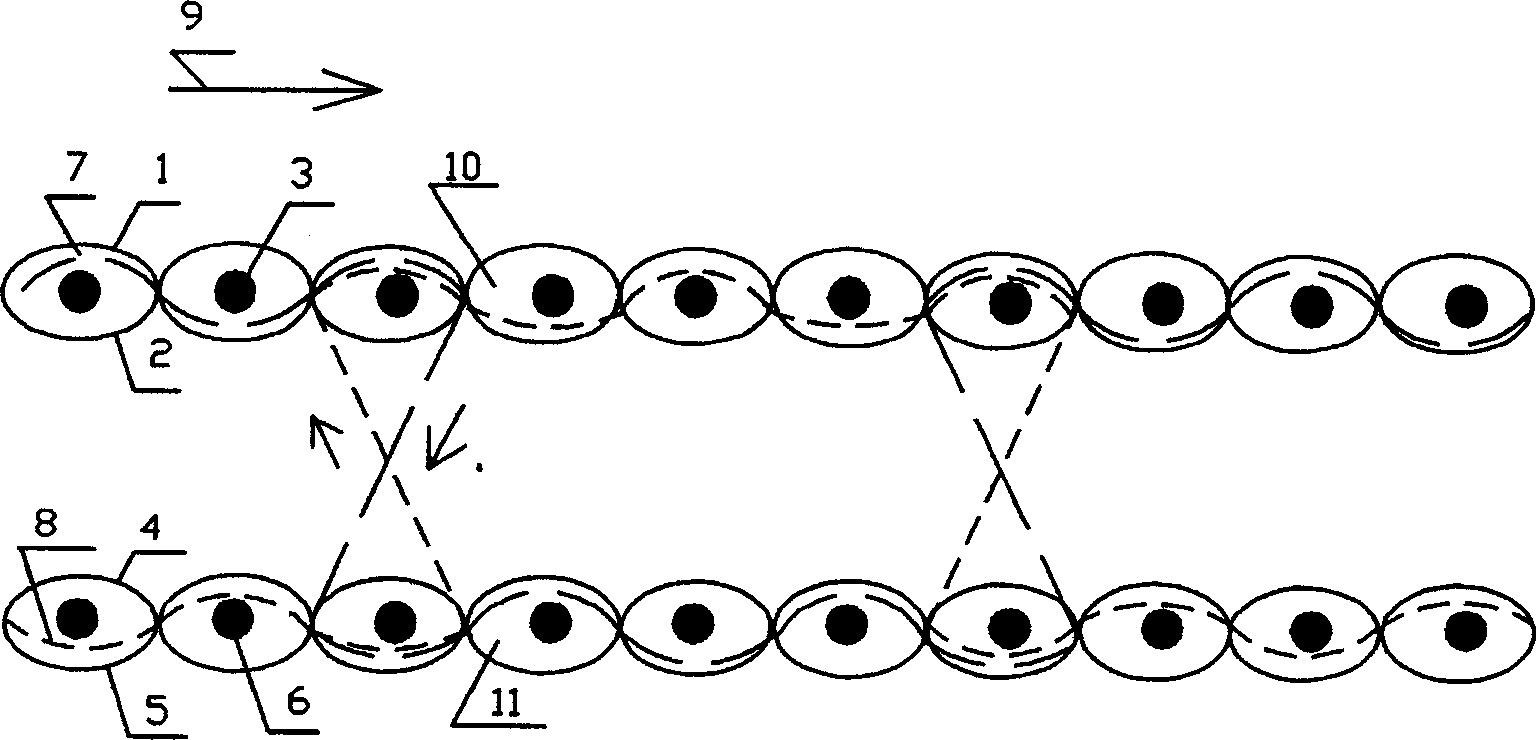

[0014] See attached figure 2 , the present invention forms the upper layer 10 of the fabric through the interweaving of warp yarns 1, 2 and weft yarns 3 of the upper layer (the ground weave is represented by plain weave); The warps 7 and 8 connect the upper and lower layers of the fabric, and the pile warps 7 and 8 are all interwoven with the same weft yarn 3 or 6 at the same time on any layer to form a symmetrical spatial form. When velvet warp 7,8 is woven from one layer of fabric to another layer, the spatial orientation of the two layers is opposite to the weft insertion direction (shown by arrow 9) of the fabric, which is "reverse" interweaving with the same weft yarn 3 or 6. by figure 2 Take the middle pile warp 7 and 8 as an example. During the transition from the upper layer 10 to the lower layer 11, the pile warp 7 is interwoven with the weft yarn 3, as shown by the arrow, it extends to the lower left and then interweaves with the weft yarn 6 On the lower layer 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com