Evaporating device and method utilizing same

A technology of vapor deposition and vapor deposition, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of low source gas use efficiency and difficulty in obtaining high-quality insulating films, etc., and achieve excellent characteristics, crystallization or annealing The effect of easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

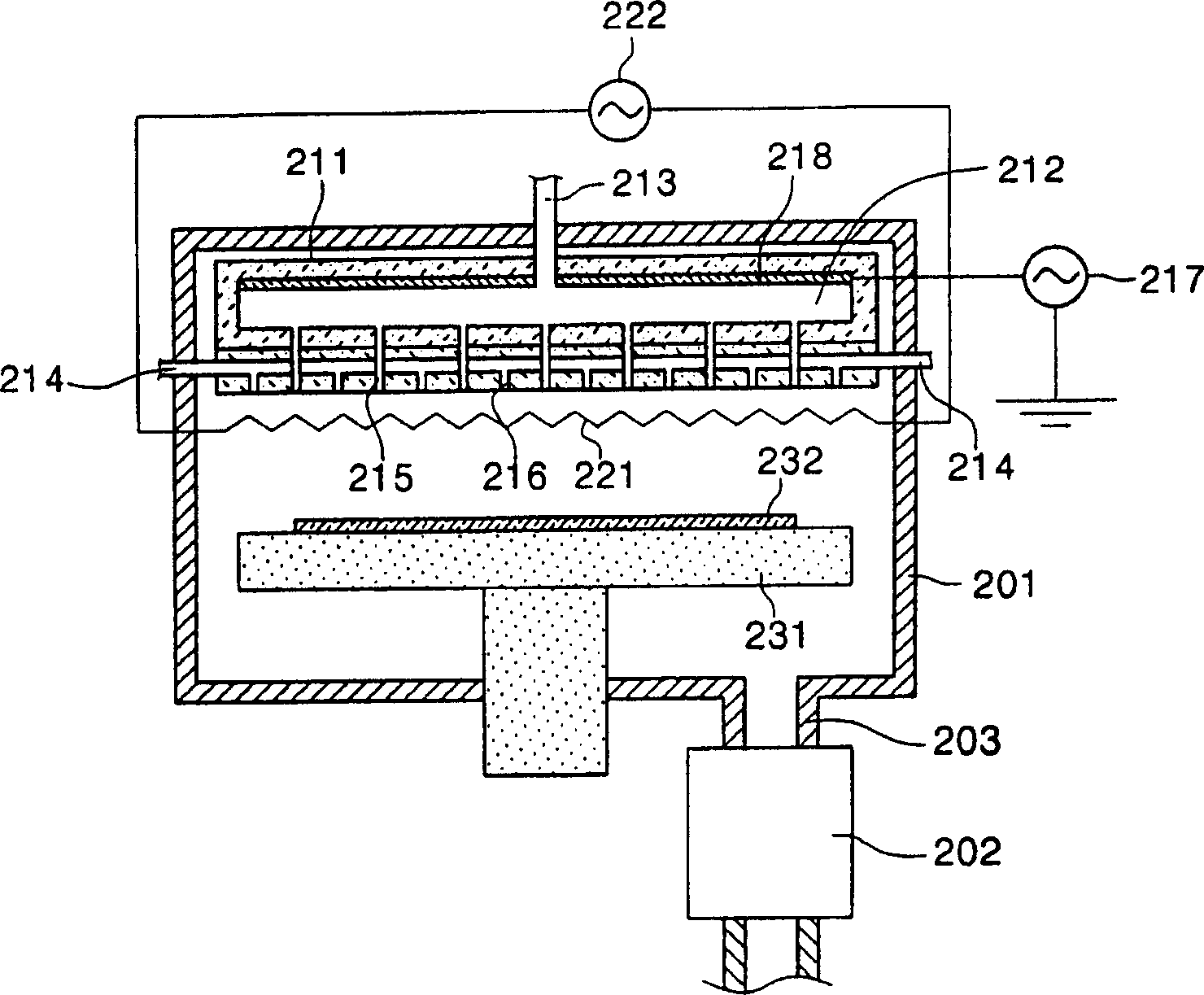

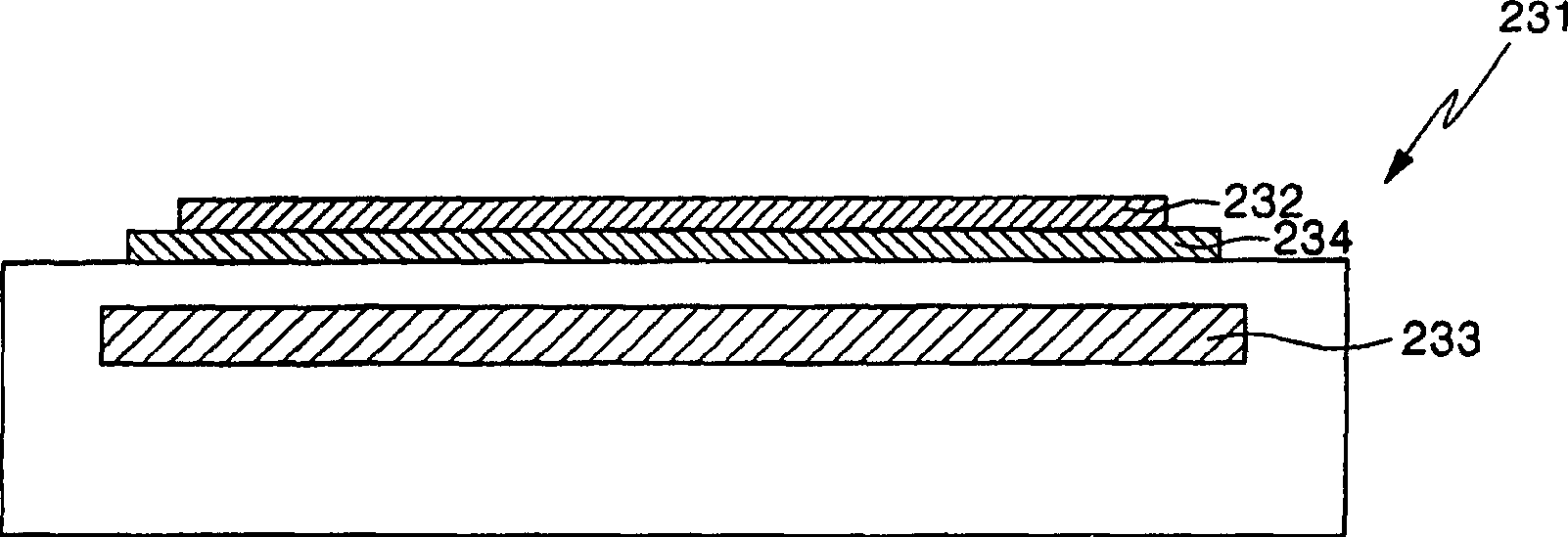

[0053] refer to figure 2 For description, the substrate 232 is placed on a jig of the vapor deposition apparatus of the present invention including a shower head and a heating body.

[0054] Next, use the vacuum pump 202 to exhaust the gas inside the chamber 201 to make the vacuum degree less than or equal to 5×10 -6 torr. The temperature of the wall of the chamber is preferably maintained at a temperature greater than or equal to 120° C., because when the temperature of the chamber is low, the evaporated material is not deposited on the substrate but deposited in the chamber. Problem spot on the wall etc.

[0055] Then, after an inert gas is injected into the first gas injection port 213 , electric power is applied to the electrode 218 to generate plasma inside the cavity 212 . At this time, since the inert gas is a gas for generating plasma, helium (He), neon (Ne), argon (Ar), or the like can be used. At this time, the flow rate of the inert gas is 1-1000 sccm. In addi...

Embodiment 2

[0063] refer to figure 2 For description, the substrate 232 is placed on a jig of the vapor deposition apparatus of the present invention including a shower head and a heating body.

[0064] Next, use the vacuum pump 202 to exhaust the gas inside the chamber 201 to make the vacuum degree less than or equal to 5×10 -6 torr. The temperature of the chamber wall is preferably maintained at a temperature greater than or equal to 120° C., because when the temperature of the chamber is low, there are evaporators that are not deposited on the substrate but deposited in the chamber. Problem spot on the wall etc.

[0065] Then, after an inert gas is injected into the first gas injection port 213 , electric power is applied to the electrode 218 to generate plasma inside the cavity 212 . At this time, since the inert gas is a gas for generating plasma, helium (He), neon (Ne), argon (Ar), or the like can be used. At this time, the flow rate of the inert gas is 1-1000 sccm.

[0066] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com