Single walled carbon nanohorn adsorptive material and method for production thereof

A technology of adsorption materials and manufacturing methods, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

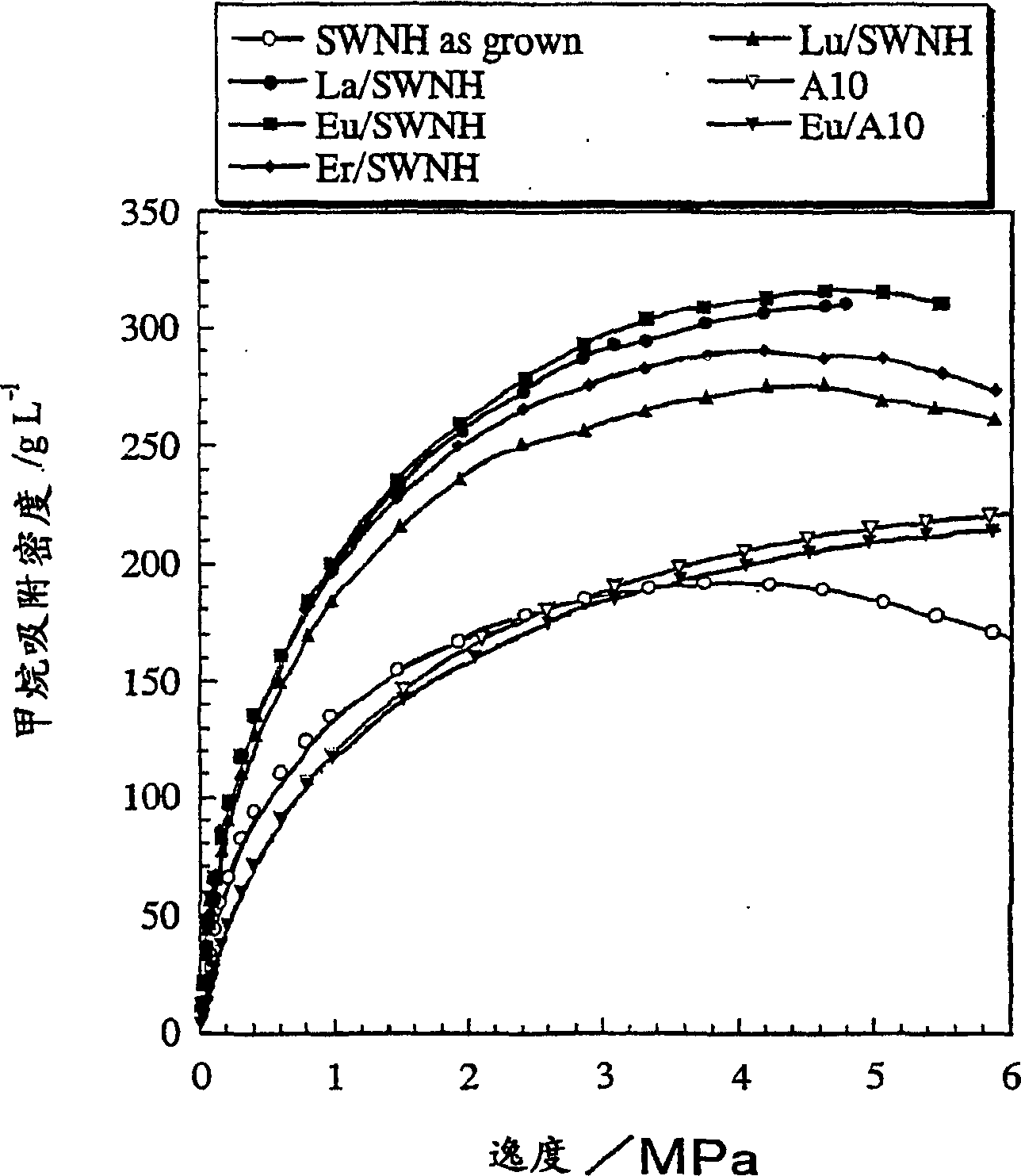

[0027] In an inert atmosphere, irradiate a solid carbon monomer with laser light to vaporize the carbon laser, and prepare a single-layer carbon nanohorn (SWNH) by the so-called laser ablation method, and suspend the single-layer carbon nanohorn in ethanol , and then add a certain amount of lanthanum nitrate ethanol solution, perform ultrasonic treatment for 5 minutes, evaporate and dry, and obtain a single-layer carbon nanohorn adsorption material loaded with lanthanum group metals. The lanthanoid elements used were La, Eu, Er, and Lu, and the supported amounts were 0.1 mmol per 1 g of SWNH. In addition, for comparison, the lanthanide metal treated in the same way was carried on the activated carbon fiber A10 by the same method as above. In addition, the lanthanoid element supported on the activated carbon fiber A10 was Eu, and the supported amount of the lanthanoid metal was 0.1 mmol per 1 g of A10.

[0028] Nitrogen adsorption measurement was performed at 77K to confirm th...

Embodiment 2

[0034]Next, the single-layer carbon nanohorn (SWNH) manufactured by laser ablation method was oxidized under oxygen flow at 693K, then suspended in ethanol, and then, a certain amount of ethanol solution of lanthanum nitrate was added, and ultrasonication was carried out for 5 minutes. After treatment, evaporate to dryness. The lanthanoid element used was Eu, and the supported amount was 0.1 mmol per 1 g of SWNH. For comparison, the methane adsorption density of a substance obtained by oxidizing SWNH in an oxygen flow at 693K was also measured. The results are shown in Table 2 and Figure 4 shown.

[0035] sample

Surface area (m 2 g -1 )

Pore capacity (mLg -1 )

SWNH-ox

1010

0.47

Eu / SWNH-ox

780

0.33

[0036] In this case, as shown in Table 2, there is a certain decrease in the pore capacity due to the loading of Eu, but from Figure 4 It can be seen that the methane adsorption density increases.

[0037]...

Embodiment 3

[0039] Suspend SWNH produced by laser ablation in ethanol, add a certain amount of ethanol solution of lanthanum nitrate elements, perform ultrasonic treatment for 5 minutes, and evaporate to dryness. Afterwards, the sample was pelletized in a pellet former. The lanthanoid element used was Eu, and the supported amount was 0.1 mmol per 1 g of SWNH. The results of measuring their methane adsorption capacity are as follows: Figure 5 shown. In addition, for comparison, samples were prepared by suspending SWNH produced by laser ablation in ethanol and granulating with a particle former. from Figure 5 It can be seen that in this case, the methane adsorption amount of Eu-loaded SWNH particles is increased by about 1.5 times compared with the case of normal SWNH particles.

[0040] As described in detail above, according to the invention of the present application, a single-layer carbon nanohorn adsorbent effective as a methane adsorbent having a large amount of methane adsorbed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com