High power 650nm semiconductor laser for digital multi-purpose optical disks and manufacturing method

A manufacturing method and multi-functional technology, which can be applied to beam sources, optical recording heads, structures of active regions, etc., and can solve problems such as low practicability, high toxicity of drugs, and difficulty in meeting the requirements of fundamental mode output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

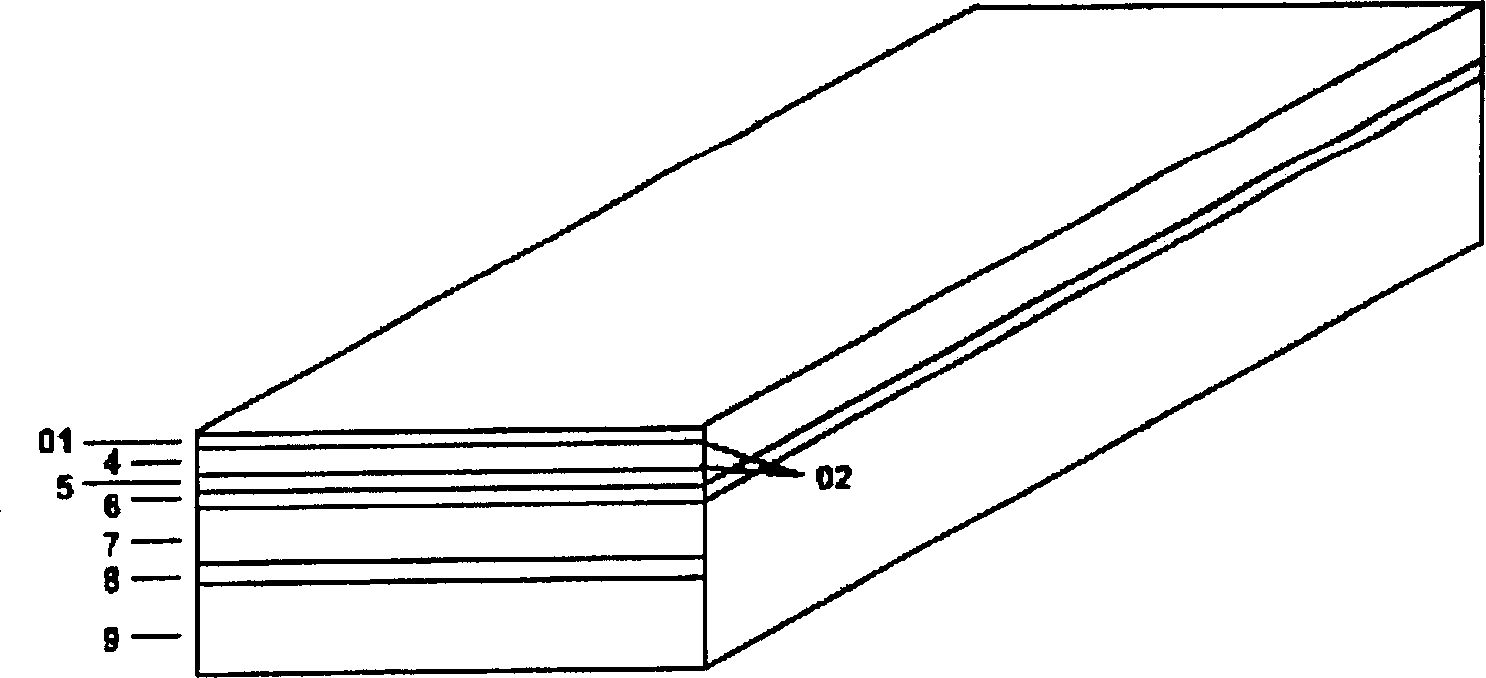

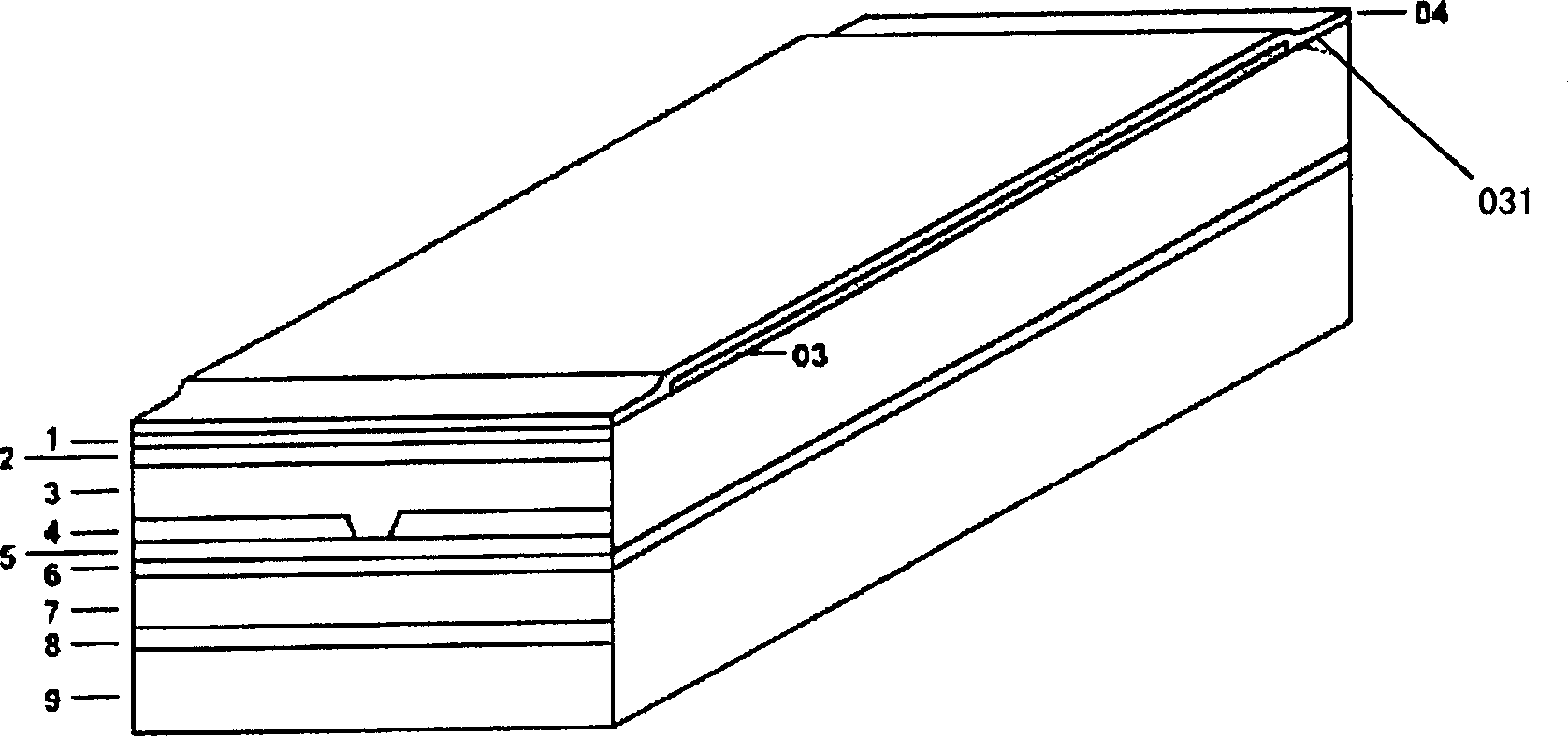

[0057] refer to Figure 5 and Figure 6 , a high-power 650nm semiconductor laser for a digital multifunctional disc of the present invention, comprising:

[0058] A substrate 9, the substrate 9 is used for epitaxial growth of the laser material structure thereon, the substrate is N-gallium arsenic on the (100) plane, and the (100) faces the A plane with an off-angle;

[0059] A buffer layer 8, which is fabricated on the substrate 9 to relieve the lattice mismatch between the substrate 9 and the material of the next layer;

[0060] An N-type cladding layer 7, the N-type cladding layer 7 is fabricated on the buffer layer 8 to limit carrier leakage;

[0061] an active region layer 6 fabricated on the cladding layer 7;

[0062] A first P-type cladding layer 5, the first P-type cladding layer 5 is fabricated on the active region layer 6 to limit carrier leakage;

[0063] A current blocking layer 4, the current blocking layer 4 is fabricated on the P-type cladding layer 5 to blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com