Vertical cavity surface emitting laser capable of controlling outer cavity polarization

A technology of vertical cavity surface emission and polarization control, which is applied in the field of VCSEL and can solve problems such as complex polarization modes and uncontrollable polarization direction of outgoing light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

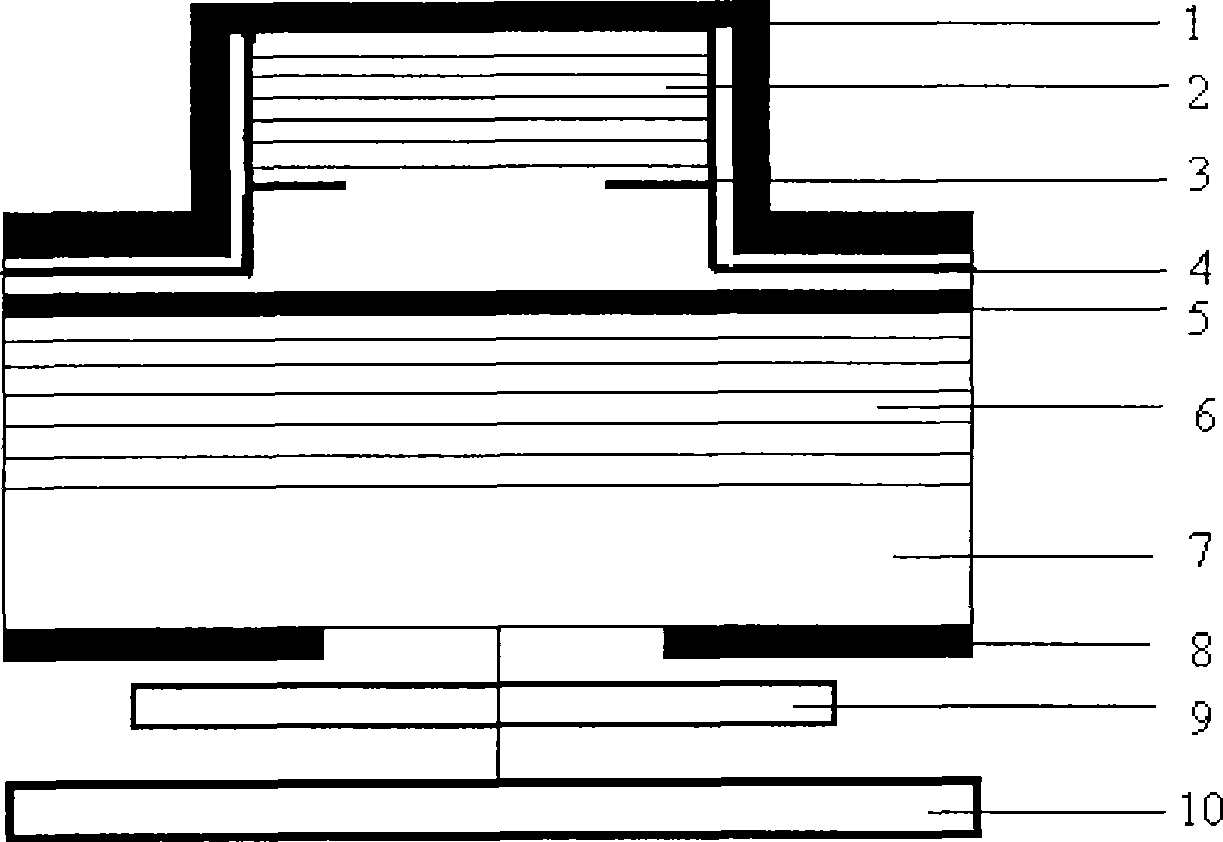

[0010] The structure of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

[0011] refer to figure 1 , a vertical cavity surface emitting laser with external cavity polarization control, mainly including p-type DBR layer 2, active layer 5, n-type DBR layer 6, GaAs substrate 7, p-type DBR layer coated on p-type DBR layer 2 The surface electrode 1, the n-face electrode 8 laid on the bottom of the GaAs substrate 7, and the external cavity high reflection mirror 10 arranged on the optical axis of the outgoing light are characterized in that there is also an external cavity high reflection mirror 10 between the outgoing light window and the external cavity high reflection mirror 10 An amorphous silicon grating 9 is provided.

[0012] The main steps of the manufacturing process of the VCSEL device of the present invention are as follows: on the VCSEL epitaxial wafer, the photolithography, corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com