Drying oven of stenter setting machine

A stenter and oven technology, applied in drying, dryer, progressive dryer and other directions, can solve problems such as high energy consumption, and achieve the effects of stable machine operation, low requirements and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

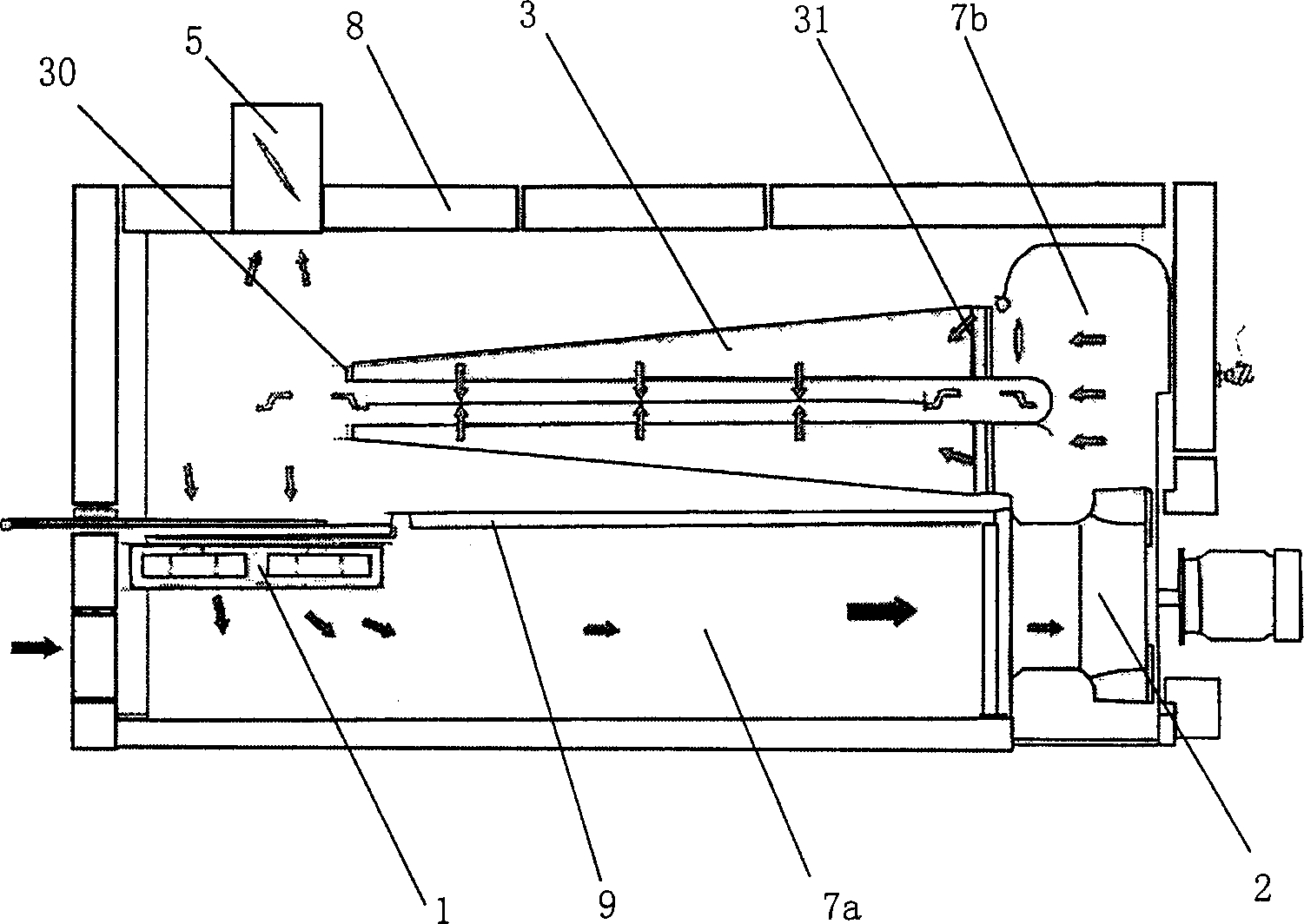

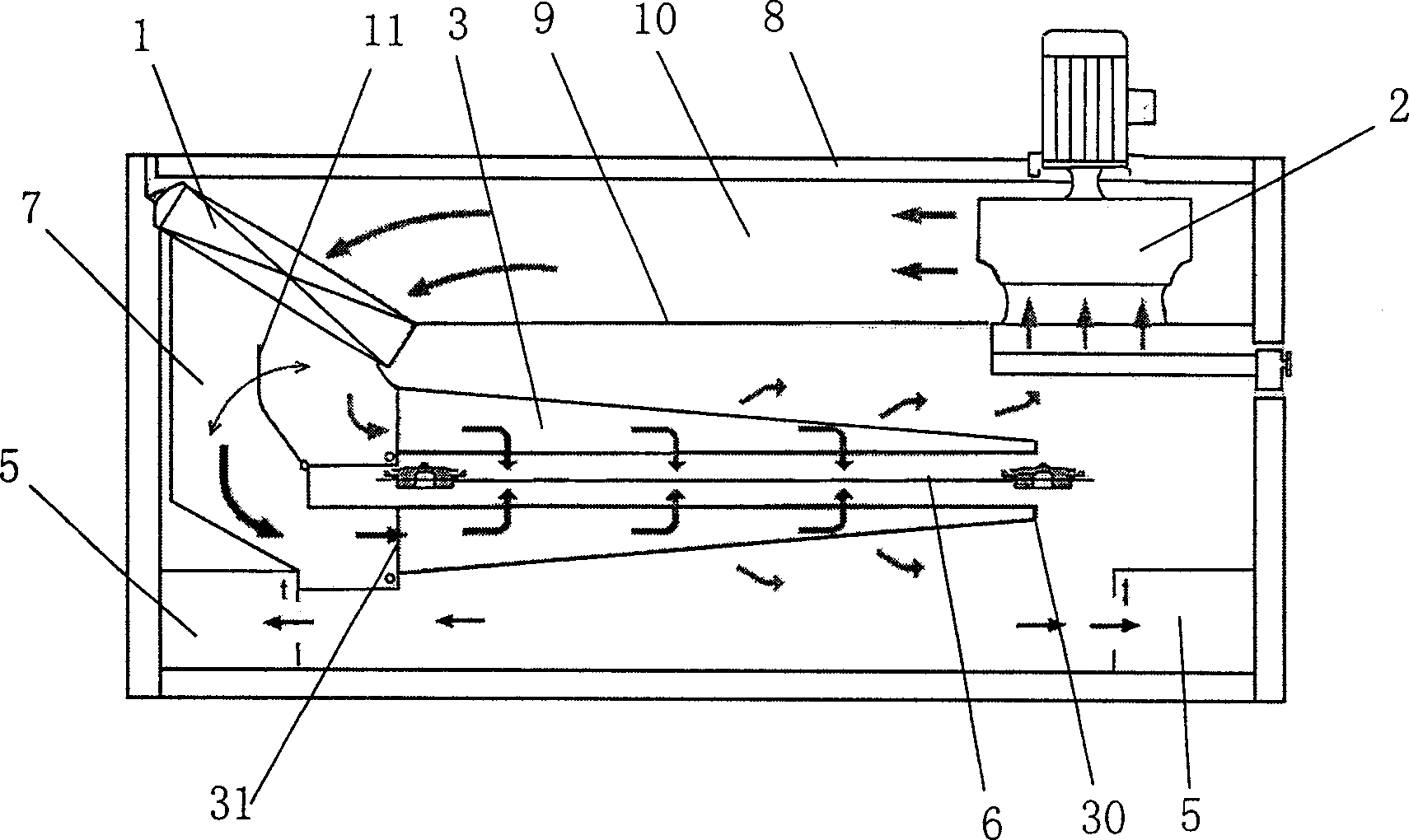

[0021] Refer to attached figure 2 , the specific embodiment of the present invention will be described in detail.

[0022] The schematic diagram of the side section structure of the stenter setting machine oven of this embodiment is as follows figure 2 Shown, be provided with cabinet 8, nozzle 3 is set in cabinet 8, fabric 6 floats thermally and bakes continuously through the gap between upper and lower nozzle 3, at the top of the cabinet outside the return air end 30 top of nozzle 3, set centrifugal Type circulating fan 2, heat exchanger 1 is arranged on the upper side of the inclination of the air inlet end 31 of nozzle 3, and the direction of inclination is to be inclined to the direction away from the fan. Below the space between them, a partition 9 is set between the nozzle 3, thereby forming a closed air duct 10 between the heat exchanger 1 and the centrifugal circulating fan 2, and only between the air inlet end 31 and the heat exchanger 1 Closed wind collection box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com