Forming method of weaving fabric with pile on both sides of single sheet

A fabric and monolithic technology, applied in the direction of fabrics, looms, flannel looms, etc., can solve the problems of heavy fabrics, velvet draping and elegant effects, and inability to form high-end clothing or decorative fabrics, etc. sense of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment and the steps of weaving double-faced velvet on the loom of the present invention are as follows:

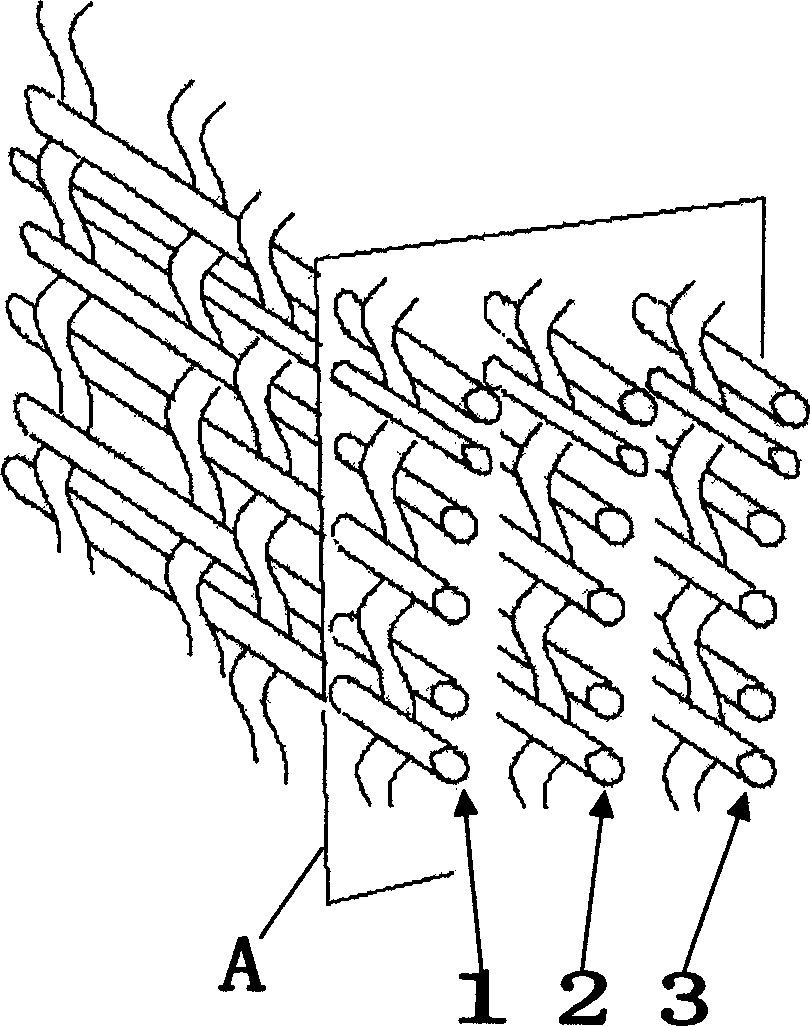

[0016] figure 1 It shows the structure of the base fabric in the embodiment of the present invention. When the fabric is off the machine, it is composed of three layers of base fabric 1, 2, and 3, wherein each layer is composed of double warp yarns to form a plain weave with a smaller longitudinal density, and The yarn of the base fabric is relatively stiff, such as strong twist yarn. Thus, the base fabric has the following properties: the yarn with higher rigidity makes the base fabric with smaller longitudinal density close to each other inside the double warp yarns with the same opening rule. Simultaneously, the closeness between the insides of the double warp yarns causes the deviation between the warp yarns of different opening rules, and as a result, a vertically dense and sparse base fabric can be formed.

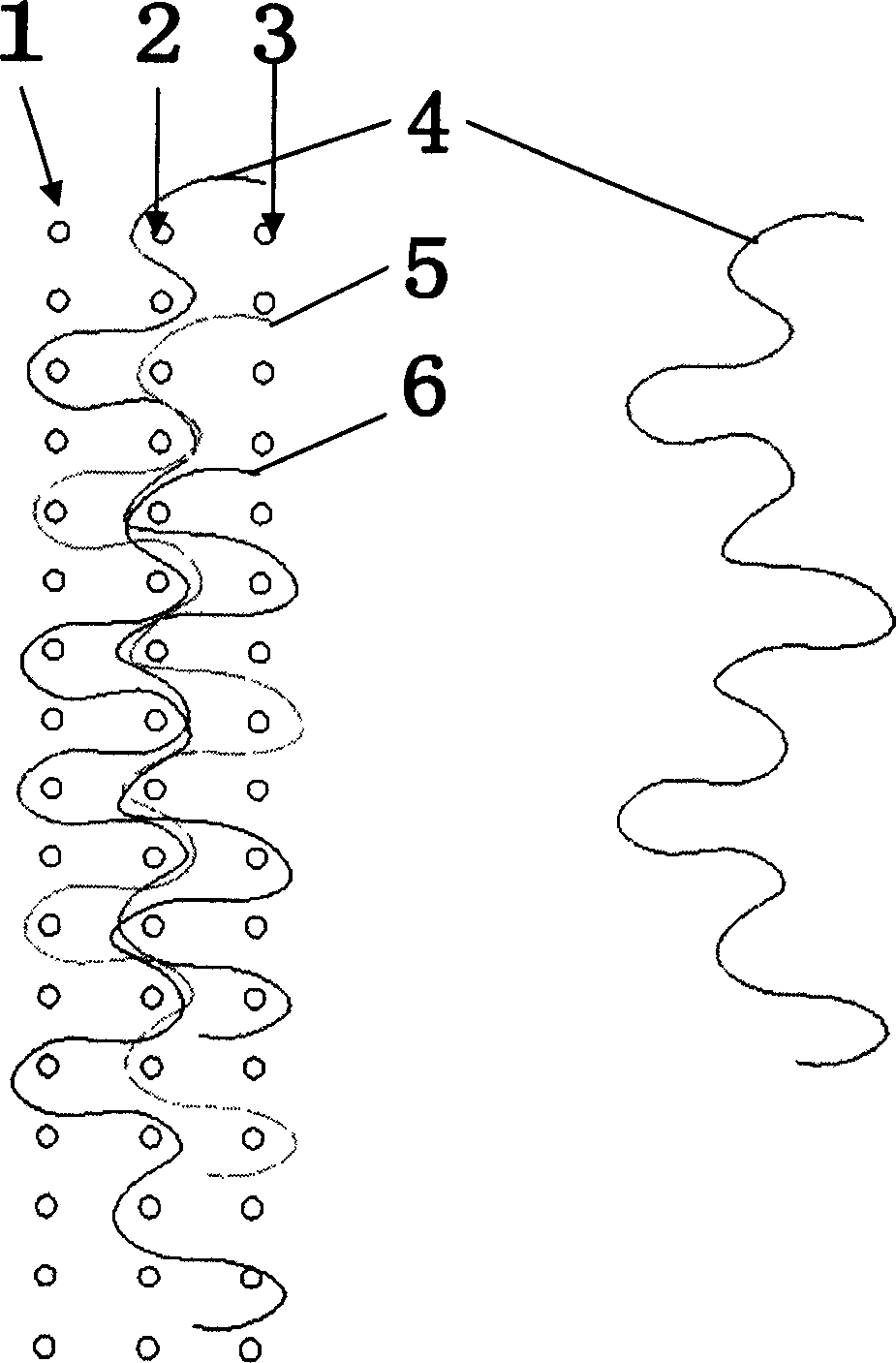

[0017] figure 2 Embodiment 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com