Gas laser oscillator

A technology of gas lasers and oscillators, applied in lasers, laser components, phonon exciters, etc., can solve problems such as difficult to prevent damage to discharge tubes, and achieve the effect of preventing insulation damage and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the following drawings, the same reference symbols are attached to the same components. For ease of understanding, the scales of these drawings are appropriately changed.

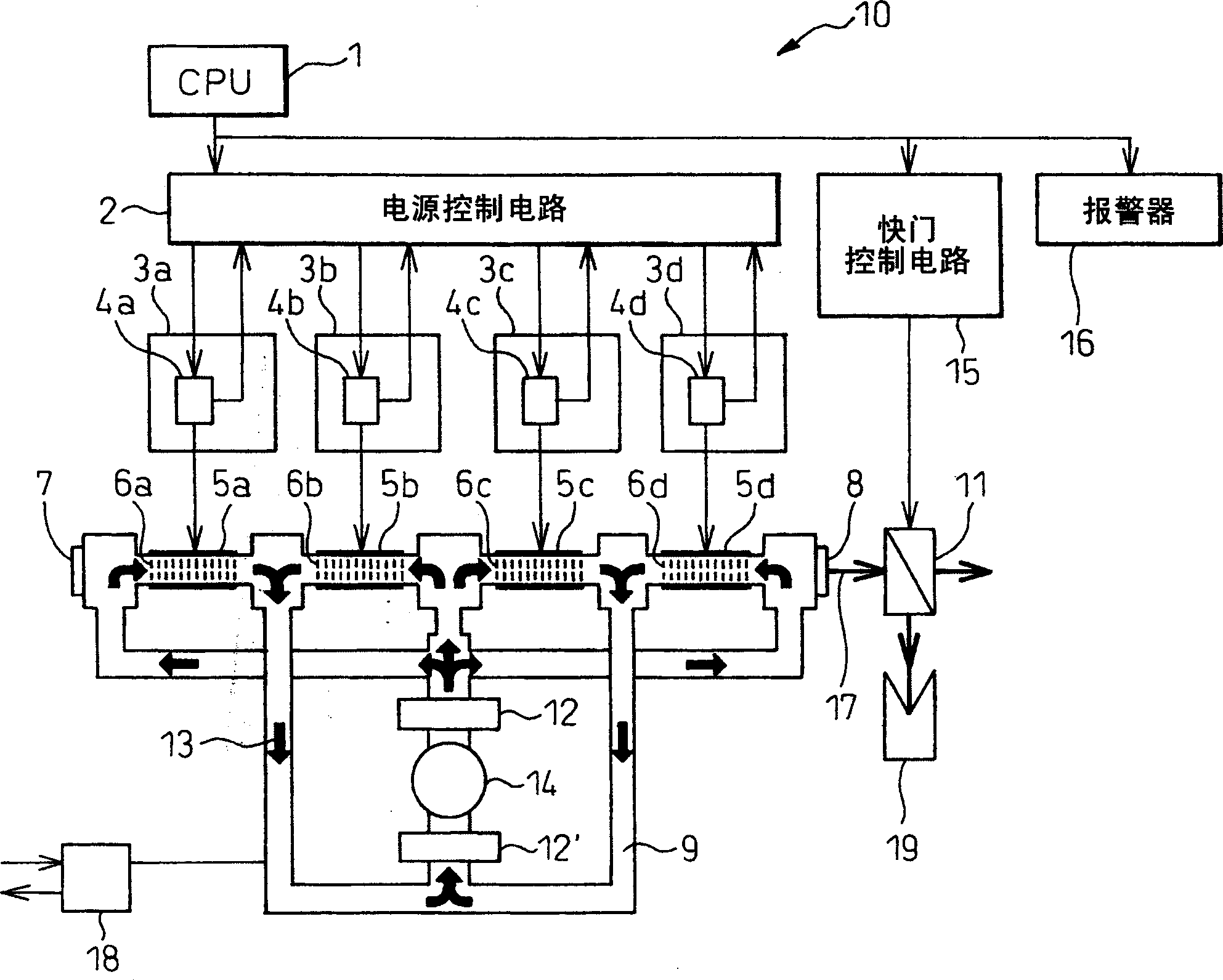

[0030] figure 1 It is a schematic diagram of a gas laser oscillator based on the present invention. like figure 1 As shown, the laser oscillator 10 is a gas laser oscillator of the induction discharge excitation type, and includes discharge tube sections 6 a - 6 b connected to a laser gas pressure control system 18 . The laser gas pressure control system 18 can supply the laser gas to the discharge tube segments 6 a to 6 b and discharge the laser gas from the discharge tube segments 6 a to 6 b. like figure 1 As shown, a non-partially penetrating rear reflector 7 (resonator internal reflector) is provided at one end of the laser oscillator 10, and a partially penetrative output reflector 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com